Bridge Report:(3110)NITTO BOSEKI the second quarter of the Fiscal Year ending March 2021

Representative and Chief Executive Officer Yuichi Tsuji | NITTO BOSEKI CO., LTD. (3110) |

|

Company Information

Market | TSE 1st Section |

Industry | Glass and ceramics products (manufacturing) |

Director, Representative and Chief Executive Officer | Yuichi Tsuji |

HQ Address | Kojimachi-odori Bldg., 2-4-1, Kojimachi, Chiyoda-ku, Tokyo |

Year-end | March |

Homepage |

Stock Information

Share Price | Shares Outstanding | Total market cap | ROE Act. | Trading Unit | |

¥4,175 | 39,935,512 shares | ¥166,730 million | 6.3% | 100 shares | |

DPS Est. | Dividend yield Est. | EPS Est. | PER Est. | BPS Act. | PBR Act. |

¥45.00 | 1.1% | ¥257.74 | 16.2 x | ¥2,413.82 | 1.7 x |

*The share price is the closing price on Nov 11. Shares outstanding, EPS and DPS are from the brief financial report for the second quarter of the Fiscal Year ending March 2021. ROE and BPS are the actual values as of the end of the previous fiscal year.

Earnings Trend

Fiscal Year | Net Sales | Operating Profit | Ordinary Profit | Net Profit | EPS | DPS |

2017/Mar Act. | 83,324 | 11,148 | 11,396 | 7,479 | 188.57 | 35.00 |

2018/Mar Act. | 84,526 | 10,837 | 11,071 | 10,253 | 263.97 | 40.00 |

2019/Mar Act. | 82,292 | 8,198 | 8,934 | 7,984 | 205.76 | 40.00 |

2020/Mar Act. | 85,722 | 8,160 | 8,202 | 5,771 | 148.73 | 45.00 |

2021/Mar Est. | 80,000 | 5,500 | 5,400 | 10,000 | 257.74 | 45.00 |

*Unit: million yen, yen. Net profit is net profit attributable to shareholders of the parent company. The same as below.

This report introduces an overview of earnings results for the second quarter of the Fiscal Year ending March 2021 of NITTO BOSEKI CO., LTD.

Table of Contents

Key Points

1. Company Overview

2. Results for the Second Quarter of the Fiscal Year ending March 2021

3. Forecast for Fiscal Year Ending March 2021

4. Taking the Post-Pandemic Era into Consideration

5. Focus Points in the Future

<Reference1:“Long-term Vision 101” and the Mid-term Business Plan “Go for Next 100”>

<Reference2: Regarding Corporate Governance>

Key Points

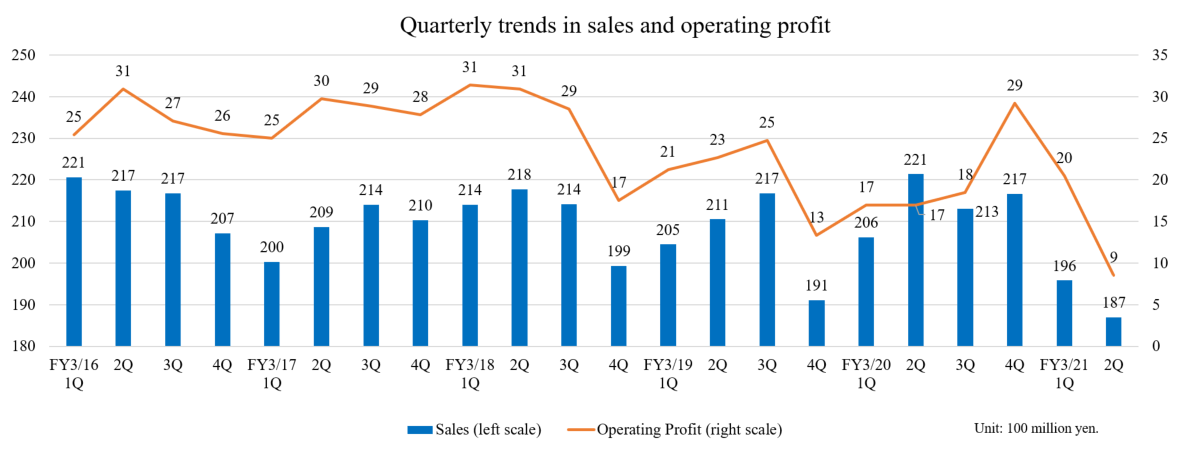

- Net sales for the second quarter of the Fiscal Year ending March 2021 decreased 10.5% year on year to 38.3 billion yen. Net sales for Glass Fiber Cloth Business increased. In addition to being affected by the novel coronavirus(COVID-19), the fire accident at the Fukushima No. 2 Factory in July temporarily reduced production of Special Glass fiber cloth in the Glass Fiber Cloth segment. Operating profit decreased 14.4% year on year to 2.9 billion yen. The costs for strengthening the business base for future growth augmented 1.2 billion yen. Among high value-added products, Special Glass, with a new melting furnace in operation, contributed to profits, but the performance of flat fiber, ultrafine yarn, and ultra-thin cloth was sluggish. Due to the impact of the COVID-19, sales of commodity products and in vitro diagnostic reagents decreased. Net profit increased 325.5% year on year to 8.8 billion yen. In addition to the selling of shares and idle land to secure capital for investment for growth, the company posted the insurance claim incomes for a fire accident that has occurred at a subsidiary in the previous fiscal year.

- Due to the effects of the U.S.-China trade conflict and the spread of the COVID-19 infection, the growth in the demand for Special Glass used in 5G base stations has been slower than initially expected. In light of the current business environment and the future outlooks, the company has revised the full year earnings forecast for the Fiscal Year ending March 31, 2021. Net sales are expected to decrease 6.7% year on year to 80 billion yen, and operating profit is estimated to decrease 32.6% year on year to 5.5 billion yen, unchanged from the previous forecast. There is no change in the dividend forecast. Just as in the preceding period, the annual dividend amount is to be 45.00 yen/share. The estimated payout ratio is 17.5%.

- The impact of the COVID-19 is projected to continue at least through this fiscal year. Under such circumstances, in addition to promoting the strengthening of a foundation for sustainable growth (capital investment and research & development investment) as planned, the company plans to save cash thoroughly, for example, by determining priorities for cash-out. As for investment in glass fiber for high value-added products, the company will expand Special Glass melting furnaces mainly in Fukushima City, Koriyama City, Moka City, and Taiwan from this fiscal year to the next fiscal year.

- There is concern about the fact that the growth in demand for Special Glass, which was relatively strong even in a difficult business environment, is slowing down, but we would like to watch the progress of performance in the third and fourth quarters as well as the status of COVID-19 infections attentively.

- In addition, the company believes that it is necessary to develop more original high value-added products that are not easily affected by economic trends. We wish to place our expectations on the improvement of their cost structure and the revision of the production process in the next Mid-term Business Plan, specific products that will enhance the company's strengths all the more and the measures for their realization, with the aim of realizing an ideal state in the post-pandemic world.

1. Company Overview

The company succeeded in the first industrialization of glass fiber in Japan through technologies of the textiles business which is its original business. It provides products for a wide range of applications, such as electronic materials and industrial materials, with consistent coverage from yarn manufacturing to glass fiber cloth processing.

Among them, Special Glass (NE-glass, T-glass) which achieves low dielectric and low thermal expansion by special composition is used in server base station and precision material for electronic devices such as smartphone and has high competitiveness. Furthermore, for “in vitro diagnostic reagents” in the Life Science Business, have the top share in more than 10 items in Japan.

1-1 Corporate History

“Koriyama Kenshi Boseki Co., Ltd” founded in Koriyama, Fukushima Prefecture in 1898, is the predecessor. The company has a history of 120 years.

Nitto Boseki Co., Ltd. was established in 1923 when Fukushima Boshoku Co., Ltd. (formerly Fukushima Seiren Seishi Co., Ltd.) acquired the ownership of the Iwashiro Spinning Plant of Katakura Seishi (formerly Koriyama Kenshi Boseki Co., Ltd) in 1918.

In 1938, it succeeded in industrialization (mass production) of glass fiber for the first time in Japan. In the world, Owens Corning Glass Fiber of the United States has achieved the industrialization of glass fiber around the same time.

In 1949, it began manufacturing glass wool for the first time in Japan.

In 1969, the company began manufacturing glass fiber cloth for printed wiring board. In 1982, it began manufacturing test reagents for blood coagulation factors. And in 1983, it succeeded in industrializing functional polymers “PAA®” for the first time in the world. As such, the company has continued to challenge new fields and expanded its business fields.

It has established the Mid- to Long-term Business Plan “Long-term Vision 101” and Mid-term Business Plan “Go for Next 100” targeting its 100th anniversary in April 2023 and is currently implementing them.

1-2 Management Philosophy

Its corporate philosophy is as follows: “Nittobo Group will, as a corporate group, enhance its significance by striving to create healthy and comfortable lifestyles, and thereby continue to contribute to the realization of prosperous communities.”

Furthermore, under the following Nittobo Declaration, it is aiming to be society’s “best partner” in collaboration with all stakeholders.

Nittobo Group aims to become the “Best Partner” of your community. (Nittobo BP Declaration) |

We will relentlessly strive to identify our customers’ needs and will find great satisfaction in steadfastly earning their Confidence and Trust. In addition, we will attach importance to sharing this satisfaction with all of our stakeholders (communities) through our products and services, including shareholders, investors, public administrations and regional communities. |

We are committed to becoming a corporate group in which the potential of our respective, independent employees is valued and thereby inspires our employees to freely and willingly share their own ideas, ultimately achieving greater results through teamwork. |

Our corporate group will provide its’ employees with an opportunity for progress and self-realization based on the belief that their progress leads to everyone’s success. We will encourage our employees to be good citizens, think deeply, observe widely, act courageously and to approach their jobs with resolve and determination. |

(From the company’s website)

1-3 Business Description

(1)Business description

The company’s business can be largely divided into three categories, namely, the “Glass Fiber Business” which manufactures and sells various products using glass fiber, “Textiles Business”, which manufactures and sells textile products for clothing, and “Life Science Business”, which manufactures and sells immunological in vitro diagnostic reagents and produces and bottles beverage.

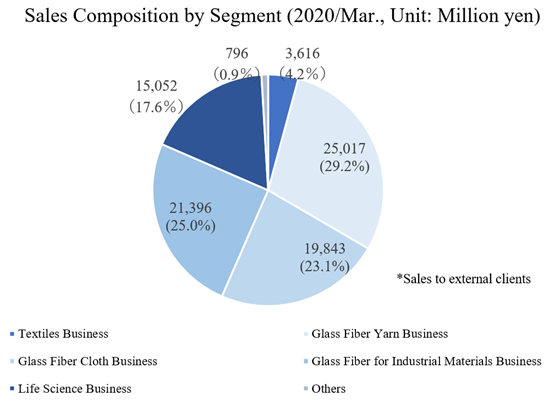

As for the reporting segments, the “Glass Fiber Business” is divided into three categories, namely, the “Glass Fiber Yarn Business,” “Glass Fiber Cloth Business,” and “Glass Fiber for Industrial Materials Business.” Together with the “Textiles Business” and “Life Science Business,” there are a total of 5 reporting segments. In addition, there is a category called “Others” which consists of the service business that are not included in the reporting segment.

Segment | Amount | Composition rate |

Textiles Business | 3,616 | 4.2% |

Glass Fiber Yarn Business | 25,017 | 29.2% |

Glass Fiber Cloth Business | 19,843 | 23.1% |

Glass Fiber for Industrial Materials Business | 21,396 | 25.0% |

Life Science Business | 15,052 | 17.6% |

Others | 796 | 0.9% |

Total Sales | 85,722 | 100.0% |

*Unit: million yen.

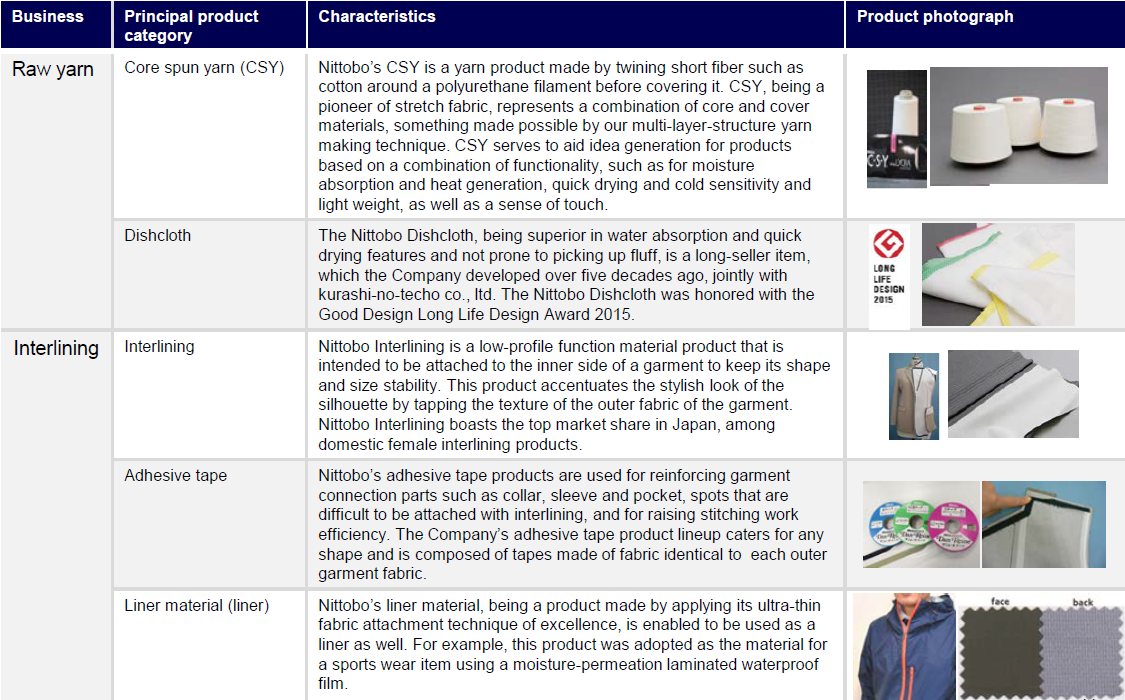

① Textiles Business

The company provides products utilizing its unique technologies to respond to the diversifying needs of customers, from yarns that are indispensable for clothing, to secondary materials and products. “C·S·Y (Core Spun Yarn)” is the double-structured textile which is the precursor of stretch fabrics. “Dan Reine” is adhesive interlining for women and has been boasting high market share. And “Nittobo Dishcloth” won the Good Design Long Life Design Award 2015.

(Source: the company)

② Glass Fiber Business

The company succeeded in the first industrialization of glass fiber in Japan. It provides products for a wide range of applications with consistent coverage from yarn manufacturing to glass fiber cloth processing.

Especially, Special Glass (NE-glass, T-glass) has low dielectric and low thermal expansion characteristics due to its special composition. It is employed as a precision material for electronic devices such as base stations, high-performance servers and smartphones, and is highly competitive.

Among them, Special Glass which achieves low dielectric and low thermal expansion by special composition is used in server, base station and precision material for electronic devices such as smartphone and has high competitiveness.

In addition, micron-level ultra-thin glass fiber cloth is used in smartphones and other devices that are becoming smaller, lighter, and more sophisticated, and is highly regarded for its quality.

The company also spearheaded the manufacturing of glass wool in Japan to be used as insulation for housing and is regarded as the pioneer of heat insulation materials with its unique technologies. In particular, high performance glass wool contributes to an energy-saving society as heat insulation materials for very airtight and highly heated insulating houses.

(Major uses)

High function electronic substrate | NE-glass has low dielectric characteristics that improve transmission loss and is now used in electronic substrates for servers in data centers and base stations. T-glass has low thermal expansion characteristics and high tensile elasticity and is now used in electronic substrates for semiconductor packages that are mounted on smartphones and high-performance servers. |

Glass fiber for composite material of smartphone body (FF) | With its unique technology, the company succeeded in making the cross section of glass fiber an oblong shape, instead of an ordinary circular shape. When used as a composite material, it helps avoid warpage and twist of molded products. It is used in the body of small electronic devices such as smartphones for which even a small distortion cannot be allowed. |

Automobile | “FRP (fiber reinforced plastic)” is widely used in various parts of automobiles as a light weight and high strength material. The company's glass fiber not only has high shape stability and workability, but also has high impact and heat resistance. The company provide new value to vehicles as they evolve toward automation and advanced driving support. |

Resin coating film material | Glass fiber cloth for membrane materials made with ultrafine grass fiber is widely used for multipurpose stadiums, soccer fields, indoor tennis courts, membrane materials for tent warehouse, and various events. |

Residential insulation (glass wool) | Glass wool exerts high insulation performance and is excellent in airtightness and soundproofing. Hence, it is used as heat insulation materials for houses and buildings to enhance the energy-saving effect. It is an environmentally friendly product since it uses 80% recycled glass and is recyclable after use. |

<What is glass fiber?>

Glass fiber is a product for which glass raw material is melted at a high temperature of 1,300℃ or higher and stretched to be fibrous.

The company succeeded in the industrialization of glass fiber for the first time in 1938 in Japan, and it developed rapidly thereafter.

Its characteristics include strength, heat resistance, non-flammability, electrical insulation and chemical resistance, and it is used for various purposes such as printed wiring boards, FRP, and building materials. For its excellent characteristics, it is being used in a wide range of industries.

(Composition, property)

As described earlier, it has characteristics such as strength, heat resistance, non-flammability, and electrical insulation. However, to be applied as electronic materials, higher level of performance including high strength, high elasticity, and low dielectric is required.

(Manufacturing method)

After raw materials of glass are melted at a high temperature of 1,300 to 1,600℃, they pass through a spinning nozzle and are reeled up to form a filament. A very precise control technique is required.The thinness of the glass fiber, which is a glass base pulled out from the machine at high speed, is 3.5 to 24 μm in diameter. (*The thinness of a human hair is about 50 to 100 μm.)

The spun glass fiber is processed into product forms according to the application.

(Major product forms)

◎Glass fiber yarn

Yarns (twisted yarns) include a single yarn which is a strand composed of several hundred filaments that are simultaneously spun and twisted in the same direction and a twisted yarn which is made by twisting several single yarns.

The “E-glass yarn,” a single yarn made of twisted strands mainly composed of filaments of 3.5 to 7.4μm, has excellent electrical insulation, heat resistance, tensile strength, and dimensional stability, and is generally used for printed wiring boards. In addition, it is highly compatible with resins due to its unique surface treatment technology for industrial materials. It is highly evaluated as a base material with good workability.

◎Glass fiber cloth

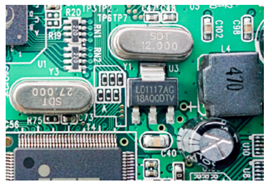

Glass fiber cloth, which is fabric (cloth form) made of glass fiber yarns, is used for a wide range of applications such as printed wiring boards, damping materials, tent films, and road reinforcement materials.

Among them, the glass fiber cloth used for printed wiring boards and electronic parts is the company’s flagship product that it boasts worldwide.

【Glass fiber cloth for printed wiring boards】

A printed wiring board is formed of the fine wiring of metals such as copper on the surface of a base body such as resin, and components including resistors, capacitors and IC chips are fixed by soldering on the wiring. It is an important part that influence the performance of all electronic equipment, including PC, smartphones, servers, medical equipment, industrial robots, automobiles, and aircraft.

Glass fiber cloth, which has characteristics of high insulation, high strength, heat resistance, and dimensional stability, is thought to be the most suitable material for a printed wiring board.

Along with remarkable development of digital technologies, electronic devices such as PC and smartphones are becoming lighter, thinner, smaller and more sophisticated, and the need for the improvement of glass fiber cloth performance is increasing.

In response to these needs, the company develops high performance glass fiber cloth products such as “Low dielectric glass fiber cloth (NE-glass),” “Low thermal expansion glass fiber cloth (T-glass),” and “Ultra-thin glass fiber cloth,” using the strengths of integrated manufacturing based on its unique technologies including glass composition development technology, fiber development technology and textile processing technology and has a high market share.

“Low dielectric glass fiber cloth (NE-glass)”

Higher speed transmission with higher frequency is becoming more common, and low dielectric materials that reduce transmission loss is required for printed wiring boards.

To address the need, the company has developed the “NE-glass” that is excellent in low dielectric constant and dissipation factor with the same characteristics as “E-glass” by lowering the component ratio of alkaline-earth elements (CaO, MgO) as compared with the conventional “E-glass” while enhancing the component ratio of boric acid (B2O3).

It is mainly used for electronic boards for data centers and base station servers.

“Low thermal expansion glass fiber cloth (T-glass)”

“T-glass” has the higher component ratio of silica (SiO2) and alumina (Al2O3) compared with the standard “E-glass” and provides significantly advanced mechanical and thermal performance of glass fiber.

Utilizing its low thermal expansion characteristics and high tensile elasticity, it realizes excellent dimensional stability and increased rigidity, and it is used as an electronic substrate for semiconductor packages mainly mounted on smartphones, high-performance servers as a high-performance electronic material. Like carbon fiber and aramid fiber, it also works well as a reinforcing material for advanced composite materials, so it is used by itself or as a hybrid material with carbon fiber in the fields of aviation, space and sports.

“Ultra-thin glass fiber cloth”

Demand for thinner glass fiber cloth is increasing as a material to respond to the trend of making lighter, thinner and smaller printed wiring boards with high density packaging. In addition to its thinness, the company’s ultra-thin glass fiber cloth has superb capacities to process fine holes both for laser and drill processing and offers great dimensional stability and surface smoothness as a laminated plate.

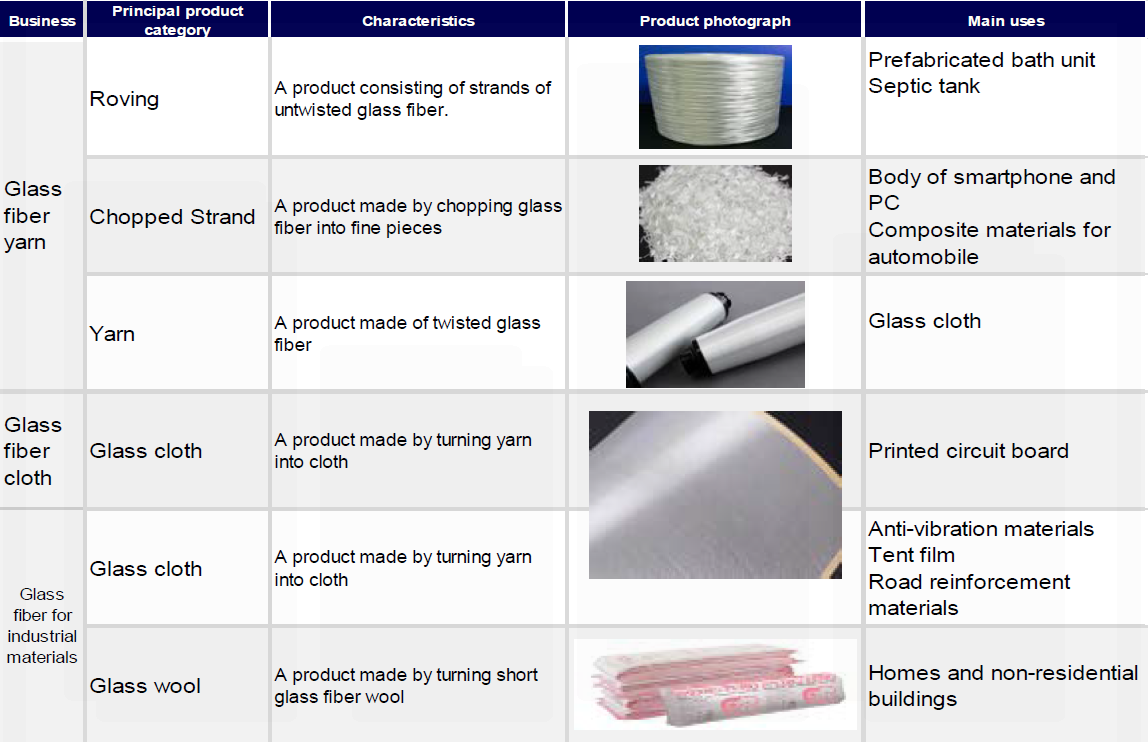

The product forms and uses by segment in the glass fiber business are as follows.

(Source: the company)

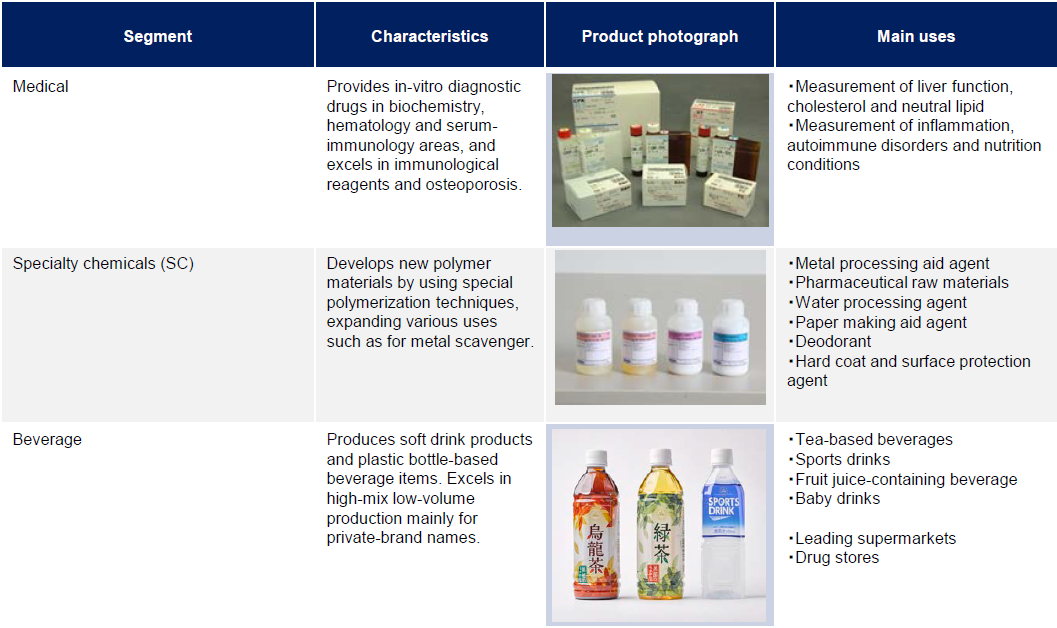

③ Life Science Business

The Life Science Business consists of the Medical Business and the Beverage Business.

The Medical Business manufactures and sells in vitro diagnostics reagents used for blood and urine tests and specialty chemicals products centered on functional polymers.

The company is achieving high quality and stable supply of the “in vitro diagnostic reagents” that are used in health checkups and thorough physical examinations to examine health status using blood or urine, by integrally manufacturing them from the antisera as the raw material to the diagnostic reagents as the final product within the Group.

The products’ high quality has been recognized, and they are supplied in medical fields globally. In Japan, the company is winning the top share with more than 10 items.

As for the Specialty Chemicals Business, the company develops products, and sells unique functional polymers (polyallylamine and polyamine series). The characteristics of this business are R&D together with chemical products/pharmaceutical manufacturers and research institutes and product proposals that capture customer needs. The company is strong in niche markets and is actively expanding the business not only in Japan but also in the global market.

The company utilizes the technologies that have been cultivated over many years to develop a business in the beverage industry.

In the Beverage Business, centered on the private brands, it is working on development of plastic bottles, beverage production and bottling.

(Source: the company)

(2)Research and development (R&D)

Since its founding, the Group has been actively promoting R&D and delivering unique products to the world.

R&D will continue to be a source of enhancing the company’s competitiveness and corporate value.

In recent years, while the needs of customers are becoming more sophisticated and diversified, global competition is intensifying. Under these circumstances, the company established new research and development site in 2017 to provide products and services with high value-added and strong originality in a timely manner with its characteristics and strengths, and to promote R&D toward the future.

The Group will continuously work on R&D from the viewpoint of expertise in each business division. At the same time, it will promote cross-sectional management by the research laboratory to pursue synergy among businesses with a focus on speed.

Furthermore, in each field, in order to accelerate research speed and expand the perspectives, the company is actively promoting joint research on industry, government and academia from the viewpoint of open innovation.

In order to further strengthen company-wide R&D capabilities, the company decided to construct a new building called “NI-CoLabo,” in Koriyama City, Fukushima Prefecture. The total cost of the construction was 2.7 billion yen and the construction were completed in April 2020. In addition to consolidating R&D divisions of each business segment into one location, it will enhance collaboration with external users. The building will be a symbol of the company’s R&D system.

Also, in July 2018, the satellite laboratory “NI-Tech” was opened at the Innovation Center of Nano Medicine in Kawasaki City as a new research and development site to strengthen the Life Sciences Business.

1-4 Characteristics and Strengths

◎ Supply products by accurately grasping needs of the times

In addition to succeeding in the industrialization of glass fiber for the first time in Japan, the company began manufacturing glass wool for the first time in Japan. As such, the company has been always leading the global and Japanese markets in the field of glass fiber. In the history of over ninety years, it has always been capturing the changes and needs of the world accurately and developing and supplying various products centered on glass fiber.

Since the company’s product is not the final product, people do not see the company’s products directly. However, it supplies many materials that are indispensable to the world and supports our lives behind the scenes.

◎ High competitiveness by unique technologies

Among many manufacturers of glass fiber in the world, it is almost the only company that realized excellent low dielectric constant and low dielectric loss tangent (NE-glass) and high dimensional stability and higher rigidity (T-glass) in the field of glass fiber cloth for electronic materials and has established a system that can stably supply sufficient volume.

In addition, having acquired the top share in Japan for more than 10 items with in vitro diagnostic reagents in the Medical Division also shows its high competitiveness with its unique technologies.

1-5 ROE Analysis

| 2014/Mar | 2015/ Mar | 2016/ Mar | 2017/ Mar | 2018/ Mar | 2019/ Mar | 2020/Mar |

ROE(%) | 6.3 | 6.8 | 7.6 | 9.8 | 12.5 | 9.1 | 6.3 |

Net Profit margin (%) | 4.53 | 5.09 | 6.49 | 8.98 | 12.13 | 9.70 | 6.73 |

Total asset turnover [times] | 0.63 | 0.64 | 0.60 | 0.59 | 0.59 | 0.55 | 0.53 |

Leverage [times] | 2.21 | 2.09 | 1.96 | 1.86 | 1.75 | 1.69 | 1.77 |

In the "Long-term Vision 101", the company’s goal figures of ROE are to achieve 10% or more.

2. Results for the Second Quarter of the Fiscal Year ending March 2021

(1) Consolidated business results

| 2020/Mar 2Q | Ratio to sales | 2021/Mar 2Q | Ratio to sales | YY change |

Net Sales | 42,762 | 100.0% | 38,280 | 100.0% | -10.5% |

Gross profit | 13,437 | 31.4% | 12,690 | 33.2% | -5.6% |

SG&A | 10,043 | 23.5% | 9,786 | 25.6% | -2.6% |

Operating Profit | 3,394 | 7.9% | 2,904 | 7.6% | -14.4% |

Ordinary Profit | 3,391 | 7.9% | 2,818 | 7.4% | -16.9% |

Quarterly Net Profit | 2,065 | 4.8% | 8,788 | 23.0% | +325.5% |

*Unit: million yen.

Sales and profit dropped.

Net sales for the second quarter of the Fiscal Year ending March 2021 decreased 10.5% year on year to 38.3 billion yen. Net sales for Glass Fiber Cloth Business increased. In addition to being affected by the COVID-19, the fire accident at the Fukushima No. 2 Factory in July temporarily reduced production of Special Glass fiber cloth in the Glass Fiber Cloth segment. Operating profit decreased 14.4% year on year to 2.9 billion yen. The costs for strengthening the business base for future growth augmented 1.2 billion yen. Among high value-added products, Special Glass, with a new melting furnace in operation, contributed to profits, but the performance of flat fiber, ultrafine yarn, and ultra-thin cloth was sluggish. Due to the impact of the COVID-19, sales of commodity products and in-vitro diagnostic reagents decreased. Net profit increased 325.5% year on year to 8.8 billion yen. In addition to the selling of shares and idle land to secure capital for investment for growth, the company posted the insurance claim incomes for a fire accident that has occurred at a subsidiary in the previous fiscal year.

(2) Trend by segments

| 2020/Mar 2Q | Ratio to sales | 2021/Mar 2Q | Ratio to sales | YY change |

Total Sales | 42,762 | 100.0% | 38,280 | 100.0% | -10.5% |

Textiles | 2,006 | 4.7% | 1,066 | 2.8% | -46.9% |

Glass Fiber Yarn | 13,122 | 30.7% | 10,806 | 28.2% | -17.6% |

Glass Fiber Cloth | 8,761 | 20.5% | 10,055 | 26.3% | +14.8% |

Glass Fiber for Industrial Materials | 10,656 | 24.9% | 9,036 | 23.6% | -15.2% |

Life Science | 7,839 | 18.3% | 6,854 | 17.9% | -12.6% |

Others | 376 | 0.9% | 461 | 1.2% | +0.3% |

Total Operating Profit | 3,394 | 7.9% | 2,904 | 7.6% | -14.4% |

Textiles | -115 | - | -419 | - | - |

Glass Fiber Yarn | 1,055 | 8.0% | 1,376 | 12.7% | +30.4% |

Glass Fiber Cloth | 1,227 | 14.0% | 1,429 | 14.2% | +16.5% |

Glass Fiber for Industrial Materials | 73 | 0.7% | 62 | 0.7% | -15.1% |

Life Science | 1,646 | 21.0% | 1,080 | 15.8% | -34.4% |

Others Adjustments | -492 | - | -624 | - | - |

*Unit: million yen. Total sales mean sales to external clients. Ratio to sales (in profit) means the ratio of profit to sales.

①Textiles Business

Sales decreased and loss increased.

Due to the declaration of a state of emergency caused by the spread of the COVID-19, department stores were affected by the voluntary restraint of business. Even after the state of emergency was lifted, consumption of clothing remained sluggish due to the shift to a new lifestyle.

②Glass Fiber Yarn Business

Sales decreased and profit increased.

Personnel costs and depreciation costs increased due to the measures to strengthen the business foundation, but with the addition of new Special Glass melting furnaces, the production of Special Glass (NE-glass yarn and T-glass yarn) for electronic materials and external sales of NE-glass yarn expanded, contributing to increasing profits. On the other hand, sales of composite materials for reinforced plastics and glass fiber yarns for electronic materials of commodity products were sluggish due to the effects of the COVID-19.

③Glass Fiber Cloth Business

Sales and profit increased.

Although affected by the fire accident (July 2020) that occurred at the Fukushima No. 2 Factory, sales of Special Glass fiber cloth for electronic materials that contribute to high-speed, large-capacity communications increased due to an increase in glass fiber yarn production volume by a new Special Glass melting furnace that started operation in the second half of the previous year. Baotek Industrial Materials Ltd. of Taiwan, which became a consolidated subsidiary in the first half of 2020/Mar, contributed to the increase in net sales. As of the end of September 2020, the production facilities at Fukushima No. 2 Factory have been restored to the state they were in before the fire accident.

④Glass Fiber for Industrial Materials Business

Sales and profit dropped.

Sales of glass fiber cloth for facility/construction materials and heat insulation materials for houses decreased due to the impact of the COVID-19. Profit and loss improved due to the elimination of temporary deterioration in profit and losses attributable to large-scale repairs carried out in the previous fiscal year, as well as the reduction of fixed costs.

⑤Life Science Business

Sales and profit dropped.

*Medical

Due to the effects of the COVID-19, sales of in vitro diagnostic reagents were sluggish both in Japan and overseas as patients refrained from going to the hospital and the postponement of regular medical examinations at companies and schools continued.

*Beverages

The volume of contracts for beverage production decreased as people refrained from going out.

(3) Financial standing and cash flows

◎Balance Sheet

| End of 2020/Mar | End of 2020/Sep |

| End of 2020/Mar | End of 2020/Sep |

Current Assets | 80,899 | 91,532 | Current liabilities | 29,808 | 31,140 |

Cash | 22,874 | 35,157 | Payables | 6,290 | 5,704 |

Receivables | 25,164 | 21,788 | ST Interest Bearing Liabilities | 13,281 | 13,086 |

Inventories | 29,364 | 32,297 | Noncurrent liabilities | 44,311 | 46,520 |

Noncurrent Assets | 91,925 | 89,226 | LT Interest Bearing Liabilities | 27,033 | 29,214 |

Tangible Assets | 63,292 | 65,976 | Total Liabilities | 74,120 | 77,660 |

Intangible Assets | 2,705 | 2,598 | Net Assets | 98,704 | 103,099 |

Investment, Others | 25,927 | 20,652 | Retained earnings | 55,574 | 63,393 |

Total assets | 172,824 | 180,759 | Total Liabilities and Net Assets | 172,824 | 180,759 |

|

|

| Total Interest-Bearing Liabilities | 40,314 | 42,300 |

*Unit: million yen

Total assets increased 7.9 billion yen from the end of the previous fiscal year to 180.8 billion yen owing to an increase in cash and deposits due to the sale of assets and an increase in tangible assets due to capital investment.

Net assets increased 4.3 billion yen from the end of the previous fiscal year to 103.1 billion yen due to an increase in retained earnings of 7.8 billion yen.

As a result, the equity ratio remained unchanged from the end of the previous fiscal year at 54.2%.

◎Cash Flows

| 2020/Mar 2Q | 2021/Mar 2Q | Increase/decrease |

Operating CF | 4,781 | 6,370 | +1,589 |

Investing CF | -10,983 | 5,070 | +16,053 |

Free CF | -6,202 | 11,440 | +17,642 |

Financing CF | 15,875 | 935 | -14,940 |

Term End Cash and Equivalents | 25,861 | 34,997 | +9,136 |

*Unit: million yen

Free CF turned positive and the cash position improved due to the sale of investment securities, noncurrent assets, etc.

3. Forecast for the Fiscal Year Ending March 2021

(1) Earnings and dividend forecast

| 2020/Mar | Ratio to sales | 2021/Mar (forecast) | Ratio to sales | YY change | Revision rate | Progress ratio |

Net Sales | 85,722 | 100.0% | 80,000 | 100.0% | -6.7% | -1.2% | 47.9% |

Operating Profit | 8,160 | 9.5% | 5,500 | 6.9% | -32.6% | 0.0% | 52.8% |

Ordinary Profit | 8,202 | 9.6% | 5,400 | 6.8% | -34.2% | 0.0% | 52.2% |

Net Profit | 5,771 | 6.7% | 10,000 | 12.5% | +73.3% | 0.0% | 87.9% |

*Unit: million yen. The revision rate is the rate of revision to the forecast announced in August 2020.

Revision of the earnings forecast

Due to the effects of the U.S.-China trade conflict and the spread of the COVID-19 infection, the growth in the demand for Special Glass used in 5G base stations has been slower than initially expected. In light of the current business environment and the future outlooks, the company has revised the full year earnings forecast for the Fiscal Year ending March 31, 2021.Net sales are expected to decrease 6.7% year on year to 80 billion yen, and operating profit is estimated to decrease 32.6% year on year to 5.5 billion yen, unchanged from the previous forecast. There is no change in the dividend forecast. Just as in the preceding period, the annual dividend amount is to be 45.00 yen/share. The estimated payout ratio is 17.5%.

The impact of the COVID-19 is projected to continue at least through this fiscal year. Under such circumstances, in addition to promoting the strengthening of a foundation for sustainable growth (capital investment and research & development investment) as planned, the company plans to save cash thoroughly, for example, by determining priorities for cash-out.

As for investment in high value-added glass fiber, the company will upgrade Special Glass melting furnaces in Fukushima City, Koriyama City, Moka City, and Taiwan, mainly from the present term and into the next term.

(2) Outlook for each segment

The outlook for each segment is as follows:

・Although 5G-related high-end electronic materials will remain strong, sales will temporarily slowdown from initial expectations due to the effects of the U.S.-China trade conflict and the COVID-19.

・Net sales of Special Glass (NE-glass/T-glass) yarn/ cloth are expected to exceed the peak on a quarterly basis which was in the first quarter (Apr. to Jun.) of the Fiscal Year ending March 31, 2021 after the fourth quarter (Jan. to Mar.) of the current fiscal year.

・The performance of in vitro diagnostic reagents will recover to almost their pre-pandemic level domestically, but the recovery of overseas will be delayed.

・The performance of commodity products for clothing, automobiles, housing, and construction will remain stagnant in the second half.

(Source: the company)

| 2020/Mar | Ratio to sales | 2021/Mar (forecast) | Ratio to sales | YY change | Revision rate | Progress ratio |

Total Sales | 85,722 | 100.0% | 80,000 | 100.0% | -6.7% | -1.2% | 47.9% |

Textiles | 3,616 | 4.2% | 2,000 | 2.5% | -44.7% | - | 53.3% |

Glass Fiber Yarn | 25,017 | 29.2% | 24,000 | 30.0% | -4.1% | +4.3% | 45.0% |

Glass Fiber Cloth | 19,843 | 23.1% | 21,000 | 26.3% | +5.8% | -8.7% | 47.9% |

Glass Fiber for Industrial Materials | 21,396 | 25.0% | 19,000 | 23.8% | -11.2% | - | 47.6% |

Life Science | 15,052 | 17.6% | 13,000 | 16.3% | -13.6% | - | 52.7% |

Others | 796 | 0.9% | 1,000 | 1.2% | +0.3% | - | 46.1% |

Total Operating Profit | 8,160 | 9.5% | 5,500 | 6.9% | -32.6% | - | 52.8% |

Textiles | -221 | - | -800 | - | - | - | - |

Glass Fiber Yarn | 3,091 | 12.4% | 2,400 | 10.0% | -22.4% | -4.0% | 57.3% |

Glass Fiber Cloth | 2,919 | 14.7% | 3,200 | 15.2% | +9.6% | -15.8% | 44.7% |

Glass Fiber for Industrial Materials | 444 | 2.1% | 100 | 0.5% | -77.5% | +100.0% | 62.0% |

Life Science | 2,878 | 19.1% | 1,800 | 13.8% | -37.5% | +12.5% | 60.0% |

Others Adjustments | -951 | - | -1,200 | - | - | - | - |

*Unit: million yen. Total sales mean sales to external clients. Ratio to sales (in profit) means the ratio of profit to sales.

4. Taking the Post-Pandemic Era into Consideration

(1) Contribution fields of Nittobo

The spread of the COVID-19 will bring significant changes in behavioral patterns and social structures. In response to this transformation, the company believes that its purpose as a corporate group that creates a healthy and comfortable lifestyle, is to pursue its strengths to contribute to the realization of a prosperous society.

The environment and needs of each business and the details of the company's contribution are as follows.

Business | Environment and needs | Contributions |

Glass Fiber Business | Next-generation high-speed communications (base stations, data centers) and devices (PCs, tablets, and smartphones) will become more sophisticated and faster due to the spread of remote work throughout the society, medical care, education, entertainment. The need to reduce weight leading to enhanced global environmental measures. | Contribution to advanced communication technologies through the provision of Special Glass.

Contribution from high value-added glass fiber for composite materials |

Life Science Business

| From "treatment to prevention of disease" (strengthening prevention and diagnosis before getting sick). | Contribution through the provision of in vitro diagnostic reagents. |

Textiles Business

| Increasing safety, environmental awareness and various material needs. | Contribution through functional auxiliary materials such as "antibacterials," "deodorants," and "recycled materials." |

The speed and capacity of 5G, which is expected to advance this year fully, are increasing in the wireless and wired markets. On the other hand, it is said that the demonstration tests for 6G, the next generation, which will have ten times the capacity of 5G will start in the period from 2023 to 2024.

The company believes that demand for its Special Glass will expand due to the rapid evolution of such communication infrastructure.

As a pioneer in the development of low dielectric glass, the company will promote research and development of "cutting edge, low dielectric and low loss" glass fiber materials for high-speed servers and switches. The company has already produced a prototype of NER-glass, which is a further developed version of NE-glass.

Regarding the "global production system," which is a source of competitiveness, the company is constructing a new factory in Taiwan in the Glass Fiber Business and aiming for its completion in the autumn of 2021. Also, to reduce supply chain risk, the company is promoting the construction of a global supply system and support for BCP by diversifying Special Glass manufacturing sites.

In the Medical Business, to achieve high quality and cost competitiveness, Nittobo established an optimal integrated production system from raw materials to diagnostic reagents, and is strengthening the vertical integration system within the group through M&A.

(2)"Long-term Vision 101" and Mid-term Business Plan "Go for Next 100."

In the Mid-term Business Plan "Go for Next 100," which ends this fiscal year, the goal is "Net Sales of 100 billion yen and an Operating Profit of 12 billion yen for the Fiscal Year ending March 2021."

Unfortunately, it is difficult to achieve it due to the impact of the COVID-19. However, the company recognizes that it could have been able to set up the base to make an "Operating Profit of 12 billion yen" if it was not for the COVID-19 impact.

In the current environment, the growth in demand for Special Glass has slowed down and the COVID-19 is strongly affecting mainly the performance of commodity products. There is no change, however, in the policy of further reinforcing the company's strengths–Special Glass and in vitro diagnostic reagents.

As it thinks of the post-pandemic society, Nittobo believes that its business can make a significant contribution to society. Thus, it will not change the direction of its Mid-term Business Plan "Go for Next 100" and “Long-term Vision 101,” and will promote investment in future growth (capital investment, R&D, etc.) as planned.

The company will formulate the next Mid-term Business Plan during the current fiscal year. The company is planning the policies of the upcoming Mid-term Business Plan centering on measures to enhance the company's strengths further and on business reforms that focus on the commodity product zone while keeping an eye on the next 10 to 20 years.

5. Focus Points in the Future.

There is concern about the fact that the growth in demand for Special Glass, which was relatively strong even in a difficult business environment, is slowing down, but we would like to watch the progress of performance in the third and fourth quarters as well as the status of the COVID-19 infections attentively.

In addition, the company believes that it is necessary to develop more original high value-added products that are not easily affected by economic trends. We wish to place our expectations on the improvement of their cost structure and the revision of the production process in the next Mid-term Business Plan, specific products that will enhance the company's strengths all the more and the measures for their realization, with the aim of realizing an ideal state in the post-pandemic world.

<Reference1:“Long-term Vision 101” and the Mid-term Business Plan “Go for Next 100”>

(1) “Long-term Vision 101” and the Mid-term Business Plan “Go for Next 100”

The company decided on “Long-term Vision 101” for surviving and growing sustainably while seeing overseas markets, as Japan is faced with the declining birthrate, the super aging population, and the decline in total demand, and defined the ideal corporate vision in Fiscal Year Ending March 2024, which is the 101st anniversary of establishment of the company, as follows: “Nittobo delivers the unique products and innovations globally from Fukushima in Japan based on customer relations and technology.”

As the first stage for achieving “Long-term Vision 101,” the company formulated the Mid-term Business Plan “Go for Next 100,” whose final year is Fiscal Year Ending March 2021, and this plan is ongoing.

The company will first establish the foundation for keeping profitability at the current level, seize a chance to grow, identify the advantages of the corporate group, and pursue it thoroughly.

(2) Activities in each business

“Long-term Vision 101” defines the ideal corporate vision of each business in Fiscal Year Ending March 2024 as follows.

Glass Fiber Business | Stable provision of high value-added products in the rapidly changing environment to consolidate our presence as market leader. |

Medical Business | Supply of high quality in vitro diagnostic reagents for self-medication |

Textiles Business | Accelerate the high value-added strategy and expand the application of textile technology to industrial material fields and make it a business which can earn even if it is small. |

① Glass Fiber Business

The themes are “reinforcing the field of electronic materials” and “reinforcing the field of industrial materials,” taking advantage of the strengths of the Glass Fiber Business.

(Strengths of the Business)

◎Product characteristics

*Superfine count yarn

Produce the world's finest yarn with a stable quality for the realization of smaller and thinner electronic devices.

*NE-glass

Low-dielectric feature and reduce transmission loss and noise. Contribute to high-speed/high-capacity communications using 5G which is expected to rapidly spread from this Fiscal Year.

*T-glass

Actualize high-strength, low thermal expansion. It is essential for high density package substrate.

◎Technical characteristics

*Have both a spinning process and a weaving process and making the integrated production possible. There are fewer companies that have both a spinning process and a weaving process on a large-scale basis.

*In the spinning process, stable production of the world's finest glass yarn (3.5m), NE-glass yarn, T-glass yarn.

*In the weaving process, actualize the optimum weaving process or processing process in line with characteristics of individual yarns, making use of the know-how of the spinning process

“Reinforcing the field of electronic materials”

The demand for high value-added Special Glass will continue to grow as the miniaturization technologies and performance of semiconductor advance with the realization of a high-speed, large-volume communication society represented by 5G. In response, the company will find more purposes of use of Special Glass such as high value-added products “T-glass” and “NE-glass,” enhance its production capacity, produce finer and thinner “E-glass,” and reinforce production capacity.

“Reinforcing the field of industrial materials”

The company introduced Special Glass to the field of industrial materials, actively entered overseas markets, and established the customer solution section. (Current: Product Planning Section)

With the establishment of the customer solution section, the company will promote new purposes of use of “T-glass,” which is now used in electronic substrates for semiconductor packages, and “NE-glass,” which is now used in electronic substrates for servers in data centers and base stations.

The company will enhance the business for industrial materials, to meet the needs for high-strength glass for aircraft and automobiles with “T-glass”

As for investment, the company will make investments mainly for boosting the production capacity, increasing their purposes of use for the high value-added products “T-glass and NE-glass,” making ultrafine “E-glass.”

Major activities of each business for the glass fiber business are as follows.

Glass Fiber Yarn | *Enhance yarn production capacity ・Enhance production capability of Special Glass (T/NE) yarn Nitto Glass Fiber Manufacturing Co., Ltd. 2020/Mar H2~ Fukushima Factory2021/Mar~ Fukushima Factory/Fuji Fiber Glass/ Nitto Glass Fiber Manufacturing Co., Ltd. 2020/Starting operation sequentially from autumn NITTOBO ASIA Glass Fiber(Taiwan) New factory2022/Mar~ ・Enhance production capacity of fine count yarn NITTOBO ASIA Glass Fiber2020/Mar H2~

*Introduce facility of Special Glass (NE-glass) for composite material Fuji Fiber Glass Co., Ltd. 2019/Mar H1~ |

Glass Fiber Cloth | *Enhance production capacity of high value-added glass fiber cloth Fukushima No.2 Factory/Enhance weaving machine's processing ability 2019/Mar H2~ *Acquired shares of Baotek Industrial Materials Ltd. (Taiwan) (August 2018) Processing process:Super-thin cloth manufacturing After 2020/Mar H2~ |

Glass Fiber for Industrial Material | *Ramp up production capacity of thin Glass Wool *Ramp up production capacity of non-formaldehyde Glass Wool |

To capture the increasing demand for both NE-glass and T-glass, the company installed new melting furnaces in the Fukushima Factory this term and plans to install and increase furnaces at three sites in Japan starting from the autumn of 2020. Also, it intends to launch a new factory in Taiwan in the autumn of 2021.

② Medical Business

The two business strategies are “strengthening each function in the value chain, especially improving the capability to procure raw materials” and “establishing a supply chain for global production, sales, and regulatory approval.”

The company will refine its integrated production system in Japan and the United States, which is its strength, and supply high value-added reagents that respond to diversification and refinement to contribute to self-medication.

In these circumstances, the company will implement the following measures for the in vitro diagnostic reagents business.

Construction of new factories | Construction of new factories in the production bases at Nittobo Medical (Japan) and Nittobo America (US). Production capacity expansion will start from 2020. |

Reinforce research production capability | *Investment in Rimco Corporation (Development and production of in vitro diagnostic reagents by using genetically modified silkworms) *Acquired Frontier Institute Co., Ltd. (R&D and production of monoclonal antibodies) *Establishment of FAN Co., Ltd. (JV with Fujikura Kasei Co., Ltd., R&D of materials for in vitro diagnostic reagents) |

Enhance raw material supply capacity | *Acquisition of Capricorn Products (Enhance antisera production capacity) |

Sales | Strengthen know-how of US sales network (acquiring Kamiya Biomedical Company as a subsidiary) |

③ Textiles Business

The company will develop following high value-added products.

Development of new functional products | *Develop interlining with functionality (deodorization, antibacterial, antifouling, cool feel, antistatic treatment), raw yarn (deodorization, water absorption, quick drying, lightweight) *Reinforce innovative fabric (windproof, cotton lining, chambray) *Develop products other than fashion clothing including sports application (e.g., backing, bandage) |

Develop environmentally-friendly products | *Fluorine-free interlinings *Expand product lineup using recycled materials *Take measures to save water in the dyeing process |

Expand into the industrial-use material field | *Reinforce collaboration with Glass Fiber Business *Early launch of products with industrial-use materials |

(3) Numerical goals

The numerical goals in “Go for Next 100” for the Fiscal Year Ending March 2021 and “Long-term Vision 101” for the Fiscal Year Ending March 2024 are as follows.

(Earnings targets)

| 2017/Mar | 2020/Mar | 2021/Mar Forecast | 2021/Mar Plan | 2024/Mar Plan |

Net Sales | 833 | 857 | 800 | 1,000 | 1,500 |

Operating Profit | 111 | 82 | 55 | 120 | 150 |

Ordinary Profit | 114 | 82 | 54 | 120 | 150 |

Net Profit | 75 | 58 | 100 | 80 | 100 |

EBITDA | 153 | 135 | 125 | 200 | - |

*Unit: 100 million yen.

(Capital expenditures and research & development)

| 2017/Mar | 2020/Mar | 2021/Mar Forecast | 2021/Mar Plan |

Research and development expenses | 14.0 | 17.0 | 20.0 | At least 20 |

Research expenses to sales ratio | 1.7% | 2.0% | 2.5% | At least 2.0% |

Capital expenditures (acceptance inspection value) | 112 | 406 | 576 | 550 |

*Unit: 100 million yen. Capital expenditures for the Fiscal Year Ending March 2017 and March 2020 are cumulative for 3 years. The capital expenditures for the Fiscal Year Ending March 2021 means the cumulative total in 4 years.

The company sets forth the business portfolio of the Fiscal Year Ending March 2024 as “development of high value-added products and expansion of overseas sales ratio” and “establishment of the Medical Business as the second pillar” to establish a stable profit structure.

(Capital expenditures, Research and development expenses, and depreciation costs)

As for capital expenditures, the company plans to invest 55 billion yen in the 4-year mid-term business plan. At the end of the Fiscal Year ended March 2020, the company made a capital investment (inspection basis) of about 40 billion yen, including M&A.

The number of staff members at the research institute also increased from 95 in the previous year to 104 in the current fiscal year. They will continue to increase the number.

<Reference2: Regarding Corporate Governance>

◎Organization type, Directors, and Auditors

Organization type | Company with audit and supervisory committee |

Directors | 7 directors, including 4 external ones |

◎Corporate Governance Report

Updated on June 26, 2020

<Basic Policy>

Our Group aims to establish a fair and transparent management system in order to conduct business activities that put importance onto social trust from our stakeholders including shareholders and investors and undertake constant review of corporate governance.

Our company introduced an executive officer system in June 2003 with the intention to make the Board of Directors more effective and expedite decision-making. As a result, a system which maximizes the effect of consolidated management has been established. Since June 2008, the business has been operated with further clarification of functions and responsibilities for business administration and business execution. Having received an approval at the ordinary general meeting of shareholders on June 26, 2014, our company has shifted to a company with committees (currently, a company with nominating committee, etc.). In the new form, our company clearly separates supervising and business execution even further and aims at “supervisory functions reinforcement and transparent business administration” and “swift execution of business and improvement of management mobility.” Our company has also built functional systems, which allow us to respond more effectively to expectations of our stakeholders including our customers, shareholders, business partners, and employees and promotes further improvement of the corporate value.

<Reasons for Non-compliance with the Principles of the Corporate Governance Code (Excerpts)>

All Principles of the Corporate Governance Code that were revised in June 2018 are implemented.

<Disclosure Based on the Principles of the Corporate Governance Code (Excerpts)>

Principle | Disclosure contents |

Principle 1-4 The so-called cross-shareholdings | [Policy concerning cross-shareholdings] Our company may hold shares of listed companies as cross-shareholdings when we determine that it will contribute to the establishment of good relationships with the Group’s important business partners for sale, material procurement, finance, etc., facilitation of smooth business activities of the Group, and maintenance and improvement of the corporate value of the Group. Meanwhile, the share of the companies that do not contribute to the maintenance and improvement of the corporate value of the Group and are judged to have little significance in holding their shares will be sold while considering the impact on the market. [Method to validate rationality of possession] Concerning holding listed stocks, for each stock, the Board of Directors regularly verifies the holding policy, which comprehensively takes into account qualitative factors such as importance of transactions, existence of technical cooperation and joint investment, and implementation of joint ventures as well as quantitative assessments that compare the overall return on investment calculated based on the dividend yield and the business profit with capital cost. Based on this examination, the company sold three stocks worth 783 million yen in the Fiscal Year 2019 and a total of 14 stocks worth 4,138 million yen in three years from the Fiscal Year 2017.

[Exercise of voting rights of cross-shareholdings] With regard to the exercise of voting rights of cross-shareholdings, our company will decide on the matter based on the factors such as whether the issuing company has an appropriate governance system and makes appropriate decisions that lead to enhancing its corporate value over the medium- and long-term, as well as whether it contributes to the enhancement of corporate value of the Group, and exercise the voting right appropriately. |

Principle 5-1 Policy for promoting constructive dialogue with shareholders | <<Policy for developing systems and implementing measures for promoting constructive dialogue with shareholders> (1) The executive officer responsible for corporate communication is assigned to supervise overall dialogue with our shareholders, and the Corporate Communication Department is a responsible department for assisting it. Being led by the executive officer, our group endeavors to create opportunities for dialogue with our shareholders, which should contribute to the continuous growth and mid/long-term improvement of the corporate value. In addition, together with the Corporate Communication Department, other departments associated with IR activities promote ongoing collaboration among departments. (2) The Group strives to continuously disclose information in a timely and appropriate manner so that parties including our customers, shareholders and investors will accurately be informed of and understand the state of the Group. To achieve this, we comply with laws and regulations related to information disclosure, stock exchange rules, etc. as well as establishing and operating appropriate systems for information disclosure. a) The Group publishes information that needs to be disclosed in accordance with domestic and international laws and regulations, stock exchange rules, etc. through our business reports, annual securities reports and annual reports for shareholders as well as making an announcement through information transmission systems at the stock exchange and press releases. b) The Group seeks to engage in fairer and broader information disclosure through our website, etc. in principle. c) Briefings for analysts and institutional investors are held immediately after announcement of half-yearly and final financial statements. d) The company issues an integrated report that integrates financial information and non-financial information, including CSR, so that the Group's medium- to long-term value creation mechanism can be better understood. (3) Feedback including opinions and concerns from shareholders and investors received through dialogue with them is collected at the Corporate Communication Department. The Department then reports to the responsible executive officer while feeding it back to the management team and Board of Directors by reporting at executive meetings when necessary. (4) The Group deals with individual inquiries and dialogue by paying sufficient attention to insider information and using only previously published and publicly known information. |

This report is intended solely for informational purposes, and is not intended as a solicitation to invest in the shares of this company. The information and opinions contained within this report are based on data made publicly available by the Company, and comes from sources that we judge to be reliable. However, we cannot guarantee the accuracy or completeness of the data. This report is not a guarantee of the accuracy, completeness or validity of said information and or opinions, nor do we bear any responsibility for the same. All rights pertaining to this report belong to Investment Bridge Co., Ltd., which may change the contents thereof at any time without prior notice. All investment decisions are the responsibility of the individual and should be made only after proper consideration. Copyright(C) 2020 Investment Bridge Co., Ltd. All Rights Reserved. |