Bridge Report:(4205)ZEON the Fiscal Year March 2020

Kimiaki Tanaka President | ZEON CORPORATION(4205) |

|

Company Information

Market | TSE 1st Section |

Industry | Chemicals |

President | Kimiaki Tanaka |

HQ Address | Marunouchi 1-6-2, Chiyoda-ku, Tokyo |

Year-end | March |

HOMEPAGE |

Stock Information

Share Price | Shares Outstanding (including treasury shares) | Total market cap | ROE Act. | Trading Unit | |

¥1,011 | 237,075,556 shares | ¥239,683million | 7.9% | 100 shares | |

DPS Est. | Dividend yield Est. | EPS Est. | PER Est. | BPS Act. | PBR Act. |

Undecided | - | Undecided | - | ¥1,176.87 | 0.9 x |

* Share price as of closing on July 20. Shares Outstanding, ROE, and BPS are based on the results in the term ended March 2020. The forecast for this year was kept undetermined, because it is currently difficult to reasonably calculate the effects of the novel coronavirus on the business activities and the financial results .

Earnings Trend

Fiscal Year | Sales | Operating Income | Ordinary Income | Net Income | EPS | DPS |

Mar. 2017 | 287,624 | 30,767 | 31,805 | 23,152 | 104.31 | 16.00 |

Mar. 2018 | 332,682 | 38,881 | 40,893 | 13,056 | 58.81 | 17.00 |

Mar. 2019 | 337,499 | 33,147 | 36,319 | 18,458 | 84.06 | 19.00 |

Mar. 2020 | 321,966 | 26,104 | 28,744 | 20,201 | 92.44 | 21.00 |

Mar. 2021 Est. | - | - | - | - | - | - |

*Unit: million yen, yen. Net income is net income attributed to parent shareholders. The same shall apply hereafter. The forecast for this year was kept undetermined, because t is currently difficult to reasonably calculate the effects of the novel coronavirus on the business activities and the financial results.

This Bridge Report presents ZEON CORPORATION’s earnings results for the fiscal year ended March 2020, and more.

Table of Contents

Key Points

1. Company Overview

2. Fiscal Year ended March 2020 Earnings Results

3. Fiscal Year ending March 2021 Earnings Forecasts

4. Measures against COVID-19

5. Progress of “Mid-term Management Plan SZ-20 Phase III”

6. Conclusions

<Reference:Regarding Corporate Governance>

<Appendix:Fact Sheet>

Key Points

- In the fiscal year March 2020, sales and profit decreased, however, the sales and profit of the specialty materials business marked a record high. The sales of the entire company were 322 billion yen, down 15.5 billion yen year on year. The sales of the elastomers business decreased 19.2 billion yen, while the sales of synthetic rubbers, latexes, and chemicals declined due to the global economic recession and the weakening market. Further, the sales of the specialty materials increased by 6.6 billion yen. Additionally, optical plastics, optical films, and battery materials have been performing well. Operating income was 26.1 billion yen, down 7 billion yen. The profit from the elastomers declined 8 billion yen due to the weakening market in Asia, etc. while the profit from the specialty materials increased 1.2 billion yen thanks to the increase in the sales volume of optical films and battery materials.

- It is currently difficult to reasonably calculate the effects of the novel coronavirus on the business activities and financial results for the fiscal year March 2021, the forecast for earnings and dividends is still to be determined.

- It is currently difficult to predict the degree of COVID-19 effects, thus for the short-term, it is probably best to closely follow the reports of each quarter. As the economy recovers when the pandemic subsides, we will pay attention to how quickly the business can expand overseas, where regulations for going out are stricter than those in Japan.

1. Company Overview

ZEON CORPORATION is a petrochemical manufacturer that maintains numerous products with a large share of the global markets including synthetic rubber used in automobile parts and tires, synthetic latex used in surgery-use gloves, and other products. The Company’s strengths include its creative technology development function, R&D structure, and high earnings generation capability. Many of the products and materials manufactured by Zeon are used in a wide variety of products including automobile parts and tires, rubber gloves, disposable diapers, cell phones, LCD televisions, perfumes and other products commonly used in everyday life. The Zeon Group is comprised of the parent company, 61 subsidiaries and 8 affiliated companies. Zeon also has manufacturing and marketing facilities in 16 countries around the world.

|

|

(Source: the company)

1-1 Company Name and Management Vision

The company name “Zeon” is derived from the Greek word for earth “geo” (phonetically pronounced “zeo” in Japanese) and the English word reflecting eternity “eon,” and reflects the Company’s principle of “deriving raw materials from the earth and perpetually contributing to human prosperity” through the development and application of creative technologies.

(Zeon’s original name “Geon,” used at the time of its establishment, was derived from the trademark acquired for the vinyl chloride plastics “Geon” from B.F. Goodrich Company in the United States, with which it had capital and collaborative technological agreements. The company name was changed to “Zeon” when the capital agreement was dissolved in 1970.)

1-2 Corporate History

Zeon was established as a joint venture company formed by the Furukawa Group of companies: Nippon Light Metal Co., Ltd., Furukawa Electric Co., Ltd., and Yokohama Rubber Co., Ltd. in April 1950 to acquire and use the vinyl chloride resins technology from B.F. Goodrich Chemicals Co.

In 1951, Goodrich acquired 35% of the shares of Zeon for full-scale technological and capital partnership, and in 1952 mass production of vinyl chloride resins began in Japan for the first time.

In 1959, Goodrich transferred synthetic rubber manufacturing technologies to Zeon, which, in turn, started Japan’s first mass production of synthetic rubber. Manufacturing facilities were also expanded to match the growing demand for automobile parts.

In 1965, use of the Company’s unique technology called Geon Process of Butadiene (GPB) for the efficient manufacture of butadiene (main raw material of synthetic rubber) from C4 fraction was operational.

Goodrich transferred its specialty synthetic rubber business to Zeon along with the shift in its main business focus toward vinyl chloride resins. Capital ties were dissolved in 1970. Along with these changes, the Company name was changed from Geon to Zeon in 1971.

Also, in 1971, Zeon developed a unique technology called Geon Process of Isoprene (GPI) and began using it to manufacture raw materials including high-purity isoprene, Petroleum plastics, and synthetic perfume ingredients from C5 fraction.

After entering the 1980s, Zeon aggressively launched new businesses in various fields including photoresists and other information materials, synthetic fragrance, and medical-related applications in addition to its main synthetic rubber business.

In 1984, production of hydrogenated nitrile rubber Zetpol®, which currently has top share of the worldwide market, began at the Takaoka Plant.

In 1990, manufacture of cyclo olefin polymer (COP) ZEONEX®, which is the main product of the specialty material business using the GPI method to extract and synthesize products, was started at the Mizushima Plant.

In 1993, Zeon entered China with its electronics materials business.

In 1999, Zeon Chemicals L.P. (Consolidated subsidiary in the United States) acquired the specialty rubber business of Goodyear Tire & Rubber Company of the United States to become the world’s top manufacturer of specialty rubber.

In 2000, Zeon discontinued production of vinyl chloride resins at the Mizushima Plant, and thus withdrew from the Company’s founding business.

Since the 21st century came, the company has been operating business actively. For example, by releasing ZeonorFilm®, an optical film for LCD, strengthening global production and sales systems, starting the commercial operation of solution-polymerized styrene-butadiene rubber(S-SBR) in Singapore, upgrading the equipment for optical films for LCD in Himi-shi, Toyama Prefecture, starting the operation of the world’s first mass-production factory for super-growth carbon nanotubes, and establishing a joint venture for manufacturing and selling S-SBR in cooperation with Sumitomo Chemical.

1-3 Business Description

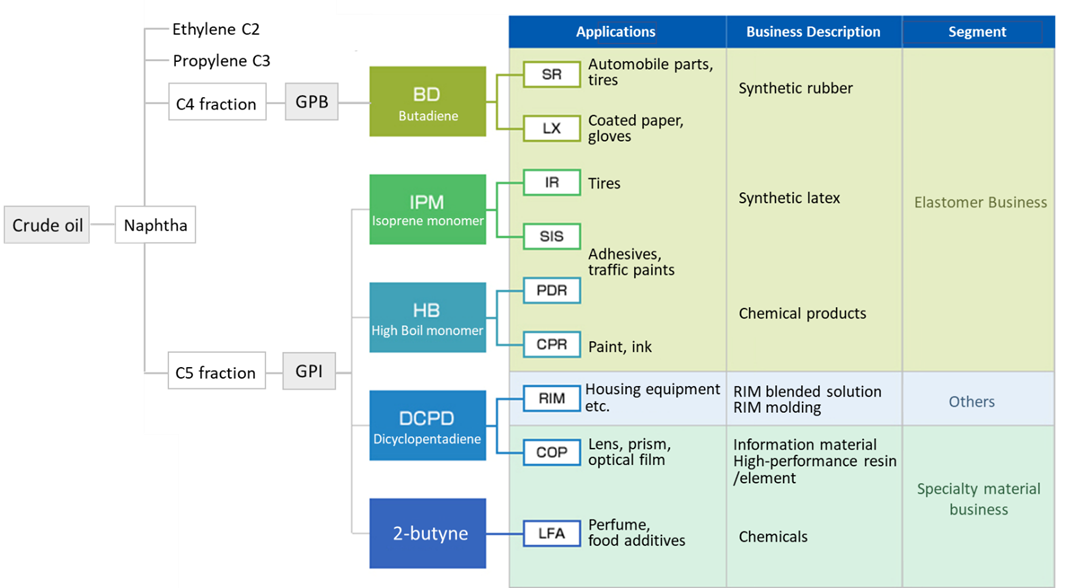

Zeon’s main products use various extracted from naphtha, which is extracted by distillation of crude oil.

Zeon uses butadiene extracted in the GPB method developed in-house from C4 fraction, isoprene monomer, piperylene, dicyclopentadiene, and 2-butyne extracted from C5 fraction using the GPI method, as raw materials to be processed into synthetic rubber, synthetic latex and various other materials.

(Source: the company)

Zeon has three business segments: 1) the elastomer business, where manufactured basic materials are sold to customers; 2) the specialty material business, where basic materials are submitted to primary processing for sale to customers as processed materials, and 3) the other business.

*Both are results for the fiscal year ended March 2020. Composition ratio is before elimination and company-wide.

Elastomer Busines

Elastomers are “high molecular compounds that have rubber-like elastic properties,” an example of which is synthetic rubber. As described in the corporate history section of this report, in 1959 Zeon became the first company in Japan to mass-produce synthetic rubber, which became the foundation underlying all of Zeon’s businesses. This business includes the segments of synthetic rubber, synthetic latex, and chemical products (Petroleum resins, thermoplastic elastomers) businesses.

1) Synthetic Rubber Business

Example of final product: Tires

Zeon provides the world’s leading tire manufacturers with the world’s highest-quality synthetic rubber for use in tires. Among the various types of synthetic rubber manufactured are styrene butadiene rubber (SBR), which promotes superior abrasion resistance, aging resistance and mechanical strength properties, butadiene rubber (BR), which includes a superior balance between elasticity, wear and low-temperature properties, and isoprene rubber (IR), which features similar properties as natural rubber but with higher quality stability. It is expected that the demand for S-SBR for fuel-efficient tires, which was developed by improving the characteristics of SBR, will grow rapidly. In order to increase the supplying capacity for coping with it, the first line of Singapore Factory started operation in September 2013, and the second line in April 2016. The supplying capacity of Singapore Factory is now 70,000 tons.

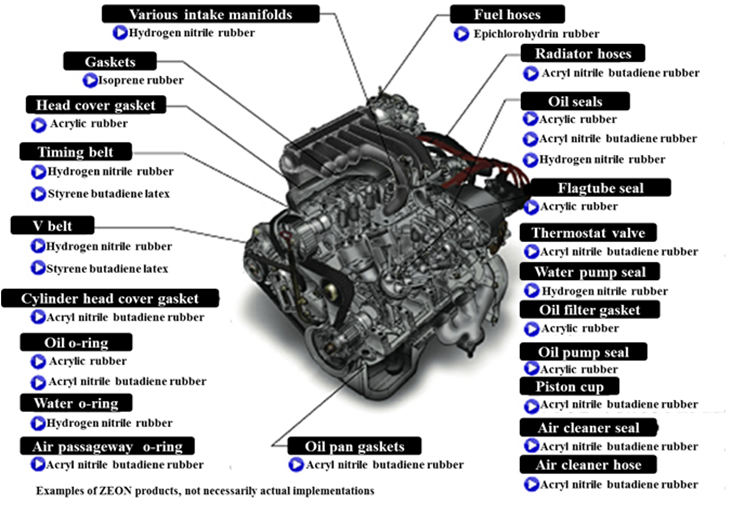

Example of product: Automobile Parts

(Source: the company)

Radiator hoses, fuel hoses, fan belts, oil seals, and various other car engine parts use specialty synthetic rubber that has superior oil resistance and heat deterioration-resistant qualities.

Zeon is the world’s number one manufacturer of specialty synthetic rubber and features high quality levels and high market share of specialty synthetic rubber automobile parts. In particular, Zeon’s Zetpol® hydrogenated nitrile rubber, used for timing belts, displays superior heat and oil resistance and mechanical strength characteristic and claims high share of the worldwide market.

Furthermore, a new grade of Zetpol® has vastly improved the performance of products using the original versions of Zetpol®.

Products using the new grade of Zetpol® are heat resistant at temperatures that exceed the limits for the original version of Zetpol® by 10 degrees centigrade, thereby extending the life of seals and gaskets, and are in strong demand for use in next generation bio-fuel engines. The new grade of Zetpol® is well suited to extrusion processing which is being leveraged to expand its usage in various hoses. Products using Zetpol® have also been well received by customers and are being used increasingly as a replacement material for more expensive competitive rubber in Japan, Asia, Europe, and North America.

2) Synthetic Latex Business

Synthetic latex is liquid rubber that synthetic rubber dispersed in water. It is used to manufacture gloves, paper coating, textile processing, adhesives, paints, and cosmetic puffs, etc. Zeon has high share of NBR latex used in cosmetic puffs in the world.

3) Chemicals Business

Zeon produces C5 fraction by its unique in-house GPI method, and turn it into materials for adhesive tapes and hot melt adhesive traffic paint binder and a wide variety of other products.

Specialty Material Business

Zeon deals in high value-added materials and parts that are created using its unique technologies including polymer design and processing technologies.

This is composed of the specialty plastics business, including optical plastics-related products and optical films, the specialty chemicals business, including specialty chemicals, battery materials, electronic materials and toners, and the medical devices business.

➀Specialty material Business

◎ Optical plastics-related products and optical films

Cyclo olefin polymer is thermoplastic polymer developed using raw material extracted from C5 fraction using GPI methods and synthesized with Zeon’s own unique technologies. The commercial products are ZEONEX® and ZEONOR®.

ZEONEX® leverages its high transparency, low water absorption, low absorptive and chemical resistance properties for use in camera and projector lenses and other optical applications and in medical use containers including syringes and vials.

ZEONOR® leverages its high transparency, transferability, and heat resistance properties for use as transparent general use engineering plastics used in light guide plates, automobile parts, semiconductor containers and a wide range of other product applications.

ZeonorFilm® is the world's first optical film by the melt extrusion method from the cyclo olefin polymer. It is excellent in optical properties, low water absorption / low moisture permeability, high heat resistance, low outgassing, and dimensional stability. Not only for displays for LCD TV, smartphones, and tablets, is it expected to be used in a wide range of applications such as OLED displays.

(Source: the company)

“Diagonally-stretched optical film” is also Zeon’s world first development.

The OELD application as anti-reflection film is progressing, and demand for small- to medium-sized flat panel display applications is growing. The company’s optical films are produced in 3 bases: Takaoka city, Toyama prefecture, Himi city, Toyama prefecture, and Tsuruga city, Fukui prefecture.

ZEOCOAT® is organic insulation material used in electronic devices such as cellphones, smartphones, and LCD televisions.

ZEOCOAT® was successful in improving both the picture quality and reliability of displays because of its high transparency, extremely low water absorption and low gas generation properties. Zeon will aggressively expand its marketing efforts for OELDs, which will be thinner displays than LCD, thin-film transistors using new semiconductors, and flexible displays.

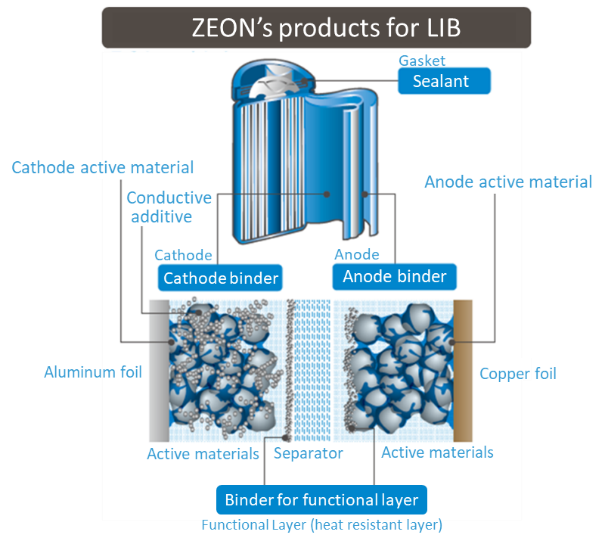

◎ Battery Materials

Zeon provides materials for Li-ion battery in this segment; anode / cathode binders, binder for functional layer (heat resistant separator), and sealant. Currently, Li-ion batteries are widely used as a power source for mobile devices such as smartphone and notebook computers and there is a strong demand for batteries with higher capacity. Adoption for electric vehicles, including hybrid and plug-in hybrid cars, and industrial power sources (such as smart grids, etc.) also have begun, since it is lightweight and compact and can store a lot of energy. On the other hand, there was a problem that lifetime tends to decrease under high temperature usage. The company has advanced the function of Li-ion battery binder and succeeded in developing an aqueous cathode binder, which greatly contributes to longer battery life. In addition, Zeon succeeded in commercializing anode binder, which can raise the storage capacity of Li-ion battery by 5% to 15%.

Zeon believes that its materials contribute to the safety, the longer life, and the more capacity of Li-ion batteries and lead to the widespread of hybrid and electric cars.

The company focused on the promising future of Li-ion batteries and worked on it for a long time. In this business segment for 2020, Zeon seeks to keep its top share in the Li-ion battery binder market, aims to expand the diffusion of new material functions that meet the needs of the application and propose functional materials to realize the next generation of new batteries.

(Source: the company)

◎ Specialty Chemicals

Zeon deals in specialty chemicals that use derivatives from C5 fraction, such as synthesized fragrances for cosmetics and flavor used in foods, characteristic solvents, and plant growth regulator. The Company holds the world’s top share of the synthesized fragrances in green note. They provide a wide range of specialty products including ingredients for intermediary bodies used in medical and agricultural chemicals, alternative solvents to CFCs, cleaning agents, urethane expanding agent, and functional ether agents.

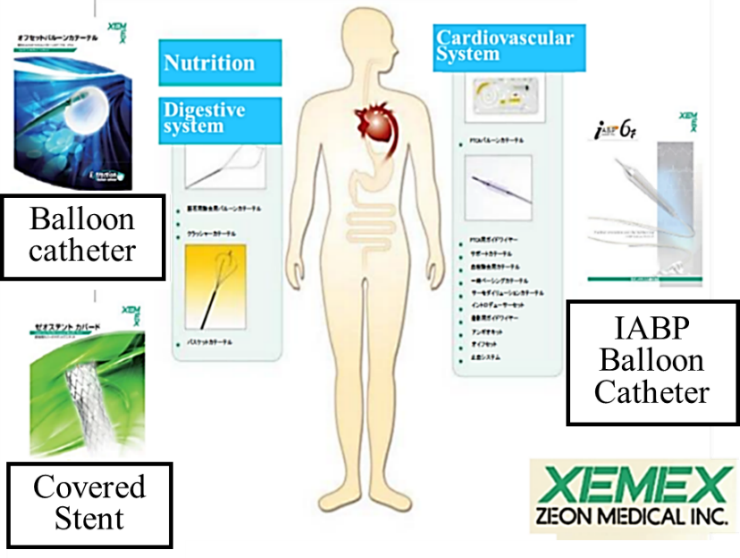

2) Medical Devices Business

The medical device market is relatively well insulated from fluctuations in the economy and is anticipated to grow with the aging society in Japan and expansion in developing countries. Furthermore, medical device companies are subject to strict laws and regulations, and they need to submit approval applications to regulatory bodies. In addition, the need to develop relationships with healthcare professionals is critical and the subsequent high barriers to entry makes this a highly attractive market.Along with the start of development of artificial kidneys in 1974, Zeon aggressively promoted its medical device business. In 1989, a subsidiary Zeon Medical Inc. was established to conduct development, manufacturing, sales, and all other functions of the medical field for the Zeon Group. Zeon has shown bountiful development track record both in gastroenterology and cardiovascular area. The Offset Balloon Catheter as a means of differentiation in the gallstone removal process and with Japan’s first biliary covered stent Zeostent Covered in the area of gastroenterology products, and the world’s smallest diameter XEMEX IABP Balloon PLUS as a device to aid the heartbeat at times of acute myocardial infarction in the area of cardiovascular products.

(Source: the company)

Currently Zeon is focusing efforts in the development of the biliary stone removal devices that eliminate pain. Zeon has a lineup of products for extracting biliary stones ranging from extremely large stones to sludge and sand with products such as XEMEX Crusher Catheter, XEMEX Basket Catheter NT, Extraction Balloon Catheter, and is aiming at a 50% share of the gallstone removal market.In March 2016, the Company launched the world’s first optical sensor FFR device as a type of guide wire. Because it uses an optical fiber sensor, mistaken readings of blood pressure measurements rarely occur. The operability as a guide wire has also gained a high evaluation.

【New Specialty Materials Development: ~Carbon Nano Tube (CNT)~ 】

Aggressive R&D activities have allowed Zeon to launch various new materials into the market, and particularly high expectation is in the development of “single-wall carbon nanotubes (CNT)”.

1) What is Single-Walled CNT?

Carbon Nanotubes (CNTs) are cylindrical nanostructure formed by hexagonal lattice of carbon atoms. In 1993, Sumio Iijima, Ph.D., head of the Applied Nanotube Research Center of the National Institute of Advanced Industrial Science and Technology (AIST), discovered this structure for the first time in the world and named Carbon Nanotubes (CNTs). CNTs are categorized into single-walled and multiple-walled CNTs. Multiple-walled CNT is relatively easy to manufacture and the developments for commercial applications already started.

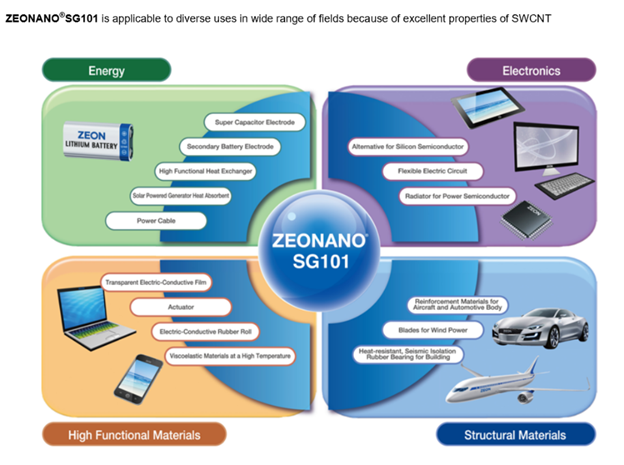

At the same time, single-walled CNT exhibits the following properties and is superior to multiple-walled CNT:- 20 times stronger than steel- 10 times more heat conductive than copper - Half as dense as aluminum- 10 times the electron mobility of silicon- lightweight but highly flexible- has extremely high electric-and heat-conductivity propertiesPossible CNT applications are electrical conductivity assistance agent in Li-ion batteries, transparent conductive film used in electronic paper and ultra-thin touch panel because of its high elasticity and strength, and as a thermal interface material. Because of its ability to absorb a wide spectrum of light, practical applications of single-walled CNT are being promoted in the area of electromagnetic wave absorbing materials for use in a wide range of fields including energy, electronics, structural materials, and other specialty materials.

(Source: Homepage of Zeon Nano Technology Co., Ltd.)

Conventional single-walled CNT has several major issues including high levels of impurities, low levels of productivity and high manufacturing costs, which are about several tens of thousands to hundreds of thousands of yen per gram.

2) Zeon’s Efforts and Position

Against this backdrop, the company aims at establishing technologies that are necessary for the commercialization of new products using single-walled CNT developed in Japan with its numerous superior qualities in response to the worldwide social demands to realize a low-carbon society.

3) Future Endeavors

Having established the mass production technology based on the super growth method, Zeon completed the CNT production facility and started mass production, the first in the world in November 2015 in its Tokuyama plant at Shunan-city, Yamaguchi Prefecture.

Zeon is the only company in the world that has established mass production technologies for single-wall CNT. About 100 companies around the world request for its product samples. Consequently, shipments of samples have already begun. Zeon has also begun to propose practical applications of this product.

At the same time, single-wall CNT is a type of nanomaterial that is extremely small and fiber shape. Therefore, there is a concern that it may have some impact upon biological processes depending upon its size and shape. Currently, the AIST is conducting standardization of the evaluation process, and activities for the OECD endpoint measurement are being conducted, with global standardization and legal and regulatory aspects being considered.

Other Business

The combination liquid for Reaction Injection Molding (RIM) using the ingredient dicyclopentadiene (DCPD) as a raw material.

1-4 ROE Analysis

| FY Mar. 14 | FY Mar. 15 | FY Mar. 16 | FY Mar. 17 | FY Mar. 18 | FY Mar. 19 | FY Mar. 20 |

ROE (%) | 11.7 | 9.8 | 8.6 | 10.3 | 5.3 | 7.2 | 7.9 |

Net income margin (%) | 6.63 | 6.20 | 6.12 | 8.05 | 3.92 | 5.47 | 6.27 |

Total asset turnover (times) | 0.82 | 0.80 | 0.75 | 0.72 | 0.78 | 0.79 | 0.78 |

Leverage (x) | 2.15 | 1.98 | 1.86 | 1.77 | 1.71 | 1.66 | 1.62 |

Since the ratio of net income to sales and leverage are showing a declining trend, ROE was below the 8% that Japanese companies are told to aim for. The company is expected to improve the profitability by focusing on the growth of the specialty materials segment.

1-5 Characteristics and Strengths

1. World’s Leading Creative Technology Development Capability

The GPB method used to manufacture butadiene from C4 fraction is the most important development in Japan’s postwar history of chemicals and is licensed to 49 plants in 19 countries around the world.

In addition, the Mizushima Plant is the world’s only plant with GPI method to extract high-purity isoprene and other effective substances from C5 fraction. This Zeon’s GPI method is a completely unique technology, which is not provided to other companies.

These two technologies represent the creative technological capabilities that are among the strengths of Zeon. They also are highly regarded and have received numerous awards in the global markets. Regarding technologies, Zeon has received 48 awards since 1960 including the GPB and GPI methods, in addition to 26 awards since 1982 for its environment conservation and safety efforts.

2. High Worldwide Share

Zetpol®, ZEONEX®, and ZEONOR® are representative of the products born from Zeon’s highly creative technologies, which have allowed it to acquire high shares of worldwide markets. In addition, their Leaf alcohol for in cosmetics and food flavorings and NBR latex for cosmetic puffs have the world’s top share.

3. R&D Structure that Continues to Yield Creative Technologies

Zeon seeks to conduct R&D activities based upon its basic corporate philosophy of “developing creative technologies in special fields of strength that enables Zeon to contribute to society by generating the world’s leading businesses.”

The Company’s main R&D center is in Kawasaki City, Kanagawa Prefecture. Zeon has also established the Precision Optics Laboratory and Medical Laboratory at the Takaoka Plant, the Specialty Chemical Product Research Facility at the Yonezawa Plant, the Toner Research Facility at the Tokuyama Plant and C5 Chemicals Laboratory at the Mizushima Plant for more efficient R&D activities to be conducted closer to the manufacturing sites. The technical support bases are in the U.S., Germany, Singapore, and China.

The R&D personnel are never satisfied with the current conditions, and always keep conscious of the threat that their competitors pose in their research activities. Furthermore, Zeon bases its valuation on a positive point awarding system that places high priority on speed and creativity. R&D expenses were formerly measured as a percentage of sales, but now it has established an annual value amount of ¥16.0 billion as an investment budget to ensure that stable R&D activities can be maintained in the future.

2. Fiscal Year ended March 2020 Earnings Results

2-1 Consolidated Earnings

| FY 3/19 | Ratio to sales | FY 3/20 | Ratio to sales | YoY | Compared with the initial forecasts | Compared with the revised forecasts |

Sales | 337,499 | 100.0% | 321,966 | 100.0% | -4.6% | -2.4% | +0.6% |

Gross profit | 96,742 | 28.7% | 91,911 | 28.5% | -5.0% | - | - |

SG&A | 63,595 | 18.8% | 65,807 | 20.4% | +3.5% | - | - |

Operating Income | 33,147 | 9.8% | 26,104 | 8.1% | -21.2% | -13% | +4.4% |

Ordinary Income | 36,319 | 10.8% | 28,744 | 8.9% | -20.9% | -10.2% | +6.5% |

Net Income | 18,458 | 5.5% | 20,201 | 6.3% | +9.4% | -8.2% | +12.2% |

*Unit: million yen.

Sales and profit decreased. The sales and profit of the specialty materials business marked a record high.

The sales of the entire company were 322 billion yen, down 15.5 billion yen year on year. The sales of elastomers decreased 19.2 billion yen, while the sales of synthetic rubber, latex, and chemicals declined due to the global economic recession and the weakening market. Further, the sales of specialty materials increased by 6.6 billion yen. Additionally, optical plastics, optical films, and battery materials have been performing well. Operating income was 26.1 billion yen, down 7 billion yen. The profit from elastomers declined 8 billion yen due to the weakening market in Asia, etc. while the profit from specialty materials increased 1.2 billion yen thanks to the increase in the sales volume of optical films and battery materials.

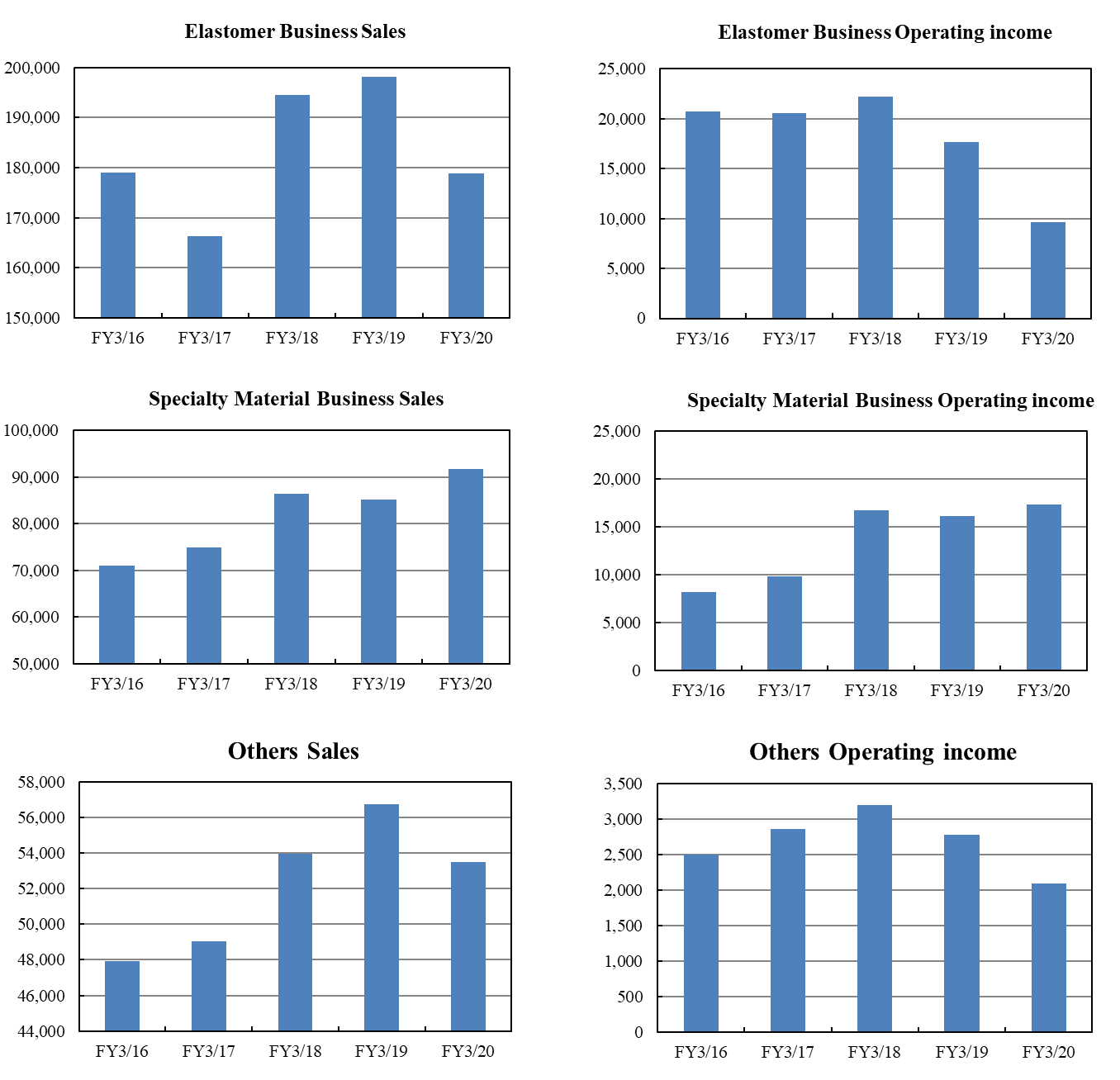

2-2 Trends by Business Segments

| FY 3/19 | FY 3/20 | YoY |

Sales |

|

|

|

Elastomer Business | 198,087 | 178,847 | -9.7% |

Specialty material Business | 85,142 | 91,749 | +7.8% |

Other Business | 56,733 | 53,473 | -5.7% |

adjustment | -2,463 | -2,103 | - |

Total | 337,499 | 321,966 | -4.6% |

Operating Income |

|

|

|

Elastomer Business | 17,691 | 9,642 | -45.5% |

Specialty material Business | 16,115 | 17,311 | +7.4% |

Other Business | 2,786 | 2,098 | -24.7% |

adjustment | -3,446 | -2,948 | - |

Total | 33,147 | 26,104 | -21.2% |

*Unit: million Yen

【Elastomers】

Sales and profit decreased.

Sales were 178.8 billion yen, down 19.2 billion yen year on year. Due to the slowdown of the global economy, the performance of synthetic rubber for the automobile industry and the general industry was sluggish for the domestic market, export, and overseas subsidiaries. The demand for latex products for cosmetic materials and general industry applications decreased causing prices to fall and thus sales decreased. The sales of chemical products declined as production volume was found to be commensurate with shipping according to the regular inspection conducted in Mizushima Plant as well as due to the decline in the Asian market.

Operating income was 9.6 billion yen, down 8 billion yen year on year. The drop in raw material prices contributed positively to business results. However, it was affected by the decline in prices due to the raw material formula, the weakening market in Asia, etc. Operating income margin was 5.4%, down 3.5 points from 8.9% in the previous fiscal year.

Among synthetic rubber, the demand for general-purpose rubber for tires was weak, but BR and S-SBR grew and secured a sales volume on par with the previous years. The sales volume of specialty rubber for the automobile industry declined 6% year on year, mainly because demand has weakened globally.

【Specialty Materials】

Sales and profit increased

Sales were 91.7 billion yen, up 6.6 billion yen year on year. As for specialty plastics, optical plastics and optical films have been performing well. As for specialty chemicals, battery materials performed well, but the sales of specialty chemicals and toners declined.

Operating income was 17.3 billion yen, up 1.2 billion yen year on year. Prices declined, the expenses related to the experimental development of optical films augmented, and the general and administrative expenses increased due to the increase in sales volume. However, the quantitative factors due to the increase in the sales volume of optical films, battery materials, etc. and the cost price factor due to the increase in the operations of optical films have contributed positively. Operating income margin was 18.9%, unchanged from the previous year.

Among battery materials, which performed well, the sales volume of the battery materials for EVs increased 13% year on year. Sales to domestic, European, and American automobile manufacturers were healthy.

The sales volume for products other than those aimed at EVs decreased 4% year on year. Growth slowed down in the first half, as it was affected by the energy storage system (ESS) fire, which occurred in Korea.

The sales volume of optical films for small and medium-sized panels increased by 9% year on year. In addition to adopting a new model, the demand for laptops and tablets increased because of COVID-19. The sales volume of products for large panels increased 9% year on year. The sales channel expansion was successful.

The sales volume of optical plastics for optical intermediates increased 21% year on year. Further, products for smartphones also performed well. The sales volume of products for the medical field and others increased 2% year on year.

【Others】

Sales and profit decreased.

The sale of the trading division and the RIM business were sluggish. Operating income rate decreased 1.0 points year on year from 4.9% to 3.9%.

2-3 Financial standing and cash flows

◎Main Balance Sheet

| End of 3/19 | End of 3/20 | Increase/decrease |

| End of 3/19 | End of 3/20 | Increase/decrease |

Current Assets | 227,238 | 214,447 | -12,791 | Current liabilities | 130,039 | 112,410 | -17,629 |

Cash | 37,534 | 32,029 | -5,505 | Payables | 82,414 | 65,691 | -16,723 |

Receivables | 78,352 | 71,332 | -7,020 | ST Interest-Bearing Liabilities | 12,125 | 10,960 | -1,165 |

Inventories | 71,125 | 73,203 | +2,078 | Noncurrent liabilities | 35,742 | 32,363 | -3,379 |

Noncurrent Assets | 197,700 | 190,684 | -7,016 | LT Interest-Bearing Liabilities | 12,000 | 10,000 | -2,000 |

Tangible Assets | 102,323 | 114,791 | +12,468 | Total Liabilities | 165,781 | 144,773 | -21,008 |

Intangible Assets | 3,197 | 3,669 | +472 | Net Assets | 259,156 | 260,358 | +1,202 |

Investment, Others | 92,179 | 72,224 | -19,955 | Capital | 256,168 | 257,218 | +1,050 |

Total assets | 424,937 | 405,131 | -19,806 | Total Liabilities and Net Assets | 424,937 | 405,131 | -19,806 |

*Unit: million yen. Receivables include electronically booked receivables; likewise, payables include electronically booked payables.

Current assets decreased 12.8 billion yen from the end of the previous term due to the decline in cash and bank deposits, receivables, etc. Although the production facilities of optical films were increased, total fixed assets decreased 7 billion yen from the end of the previous term due to the increase in depreciation expenses, the decline in investment securities, etc. and total assets decreased 19.8 billion yen from the end of the previous term.

Total liabilities decreased 21 billion yen from the end of the previous term due to the decrease in payables, etc. Net assets increased 1.2 billion yen from the end of the previous term owing to the increase in retained earnings and such.

As a result, the capital-to-asset ratio grew 3.2 points from the end of the previous term to 63.5%. D/E ratio was 0.08, down 0.01 points from 0.09 at the end of the previous term.

3. Fiscal Year ending March 2021 Earnings Forecasts

(1) Earnings Forecast

It is currently difficult to reasonably calculate the effects of the novel coronavirus on the business activities and financial results for the fiscal year March 2021, the forecast for earnings and dividends is still to be determined.

(2) Current correspondence

Since there is no prospect of the convergence of the new coronavirus, and the risk of long-term impact cannot be dispelled, the Emergency Response Headquarters has been established to respond immediately to unforeseen situations.

All offices and bases will continue to thoroughly prevent infection, and if cases of infection occur, they will promptly deal with the infection in accordance with the response measures.

4. Measures against COVID-19

The company has been swiftly and accurately taking measures, mainly the following 3 since January.

(1) Main countermeasures

① Securing the employees’ health and safety

The company put securing the health and safety of its employees and their families as well as contributing to society as its priority. Since January, it has been implementing infection-preventing measures including employing the work-from-home and staggered hours scheme, postponing or canceling events, stopping overseas business trips, limiting domestic business travel and movement, calling back overseas resident employees, supporting overseas bases by the headquarters, and practicing self-isolation during weekends and holidays. The headquarters’ work-from-home ratio is 95%.

② Stable financing

The current ratio at the end of March 2020 was 191% and the ratio of liquidity on hand was 1.2 months, thus there is no concern over funding difficulties.

Moreover, the company has an issuance limit of 50 billion yen on CP (current outstanding balance is 0 yen). Additionally, in order to avoid liquidity risks if the economy recession prolongs, the company plans to set a commitment line (the planned amount is 50 billion yen), which the company considers not only beneficial as a countermeasure against the current crisis but also effective for maintaining the supply chain.

③ Maintaining the supply chain

As for domestic plants and overseas manufacturing bases, the company has established infection preventive measures and operations are proceeding almost as usual.

Regarding overseas sales bases, the company employed infection preventive measures including work-from-home schemes and will continue to operate according to the situation of customers, etc.

(2) Future measures

The company has established an emergency headquarters, collected information about the business environment and such, and is currently implementing measures such as inventory and costs reductions in order to avoid sharp declines in sales due to the rapidly recessing global economy.

Moreover, based on this experience, the company plans to fully utilize its risk management system.

5. Progress of “Mid-term Management Plan SZ-20 Phase III”

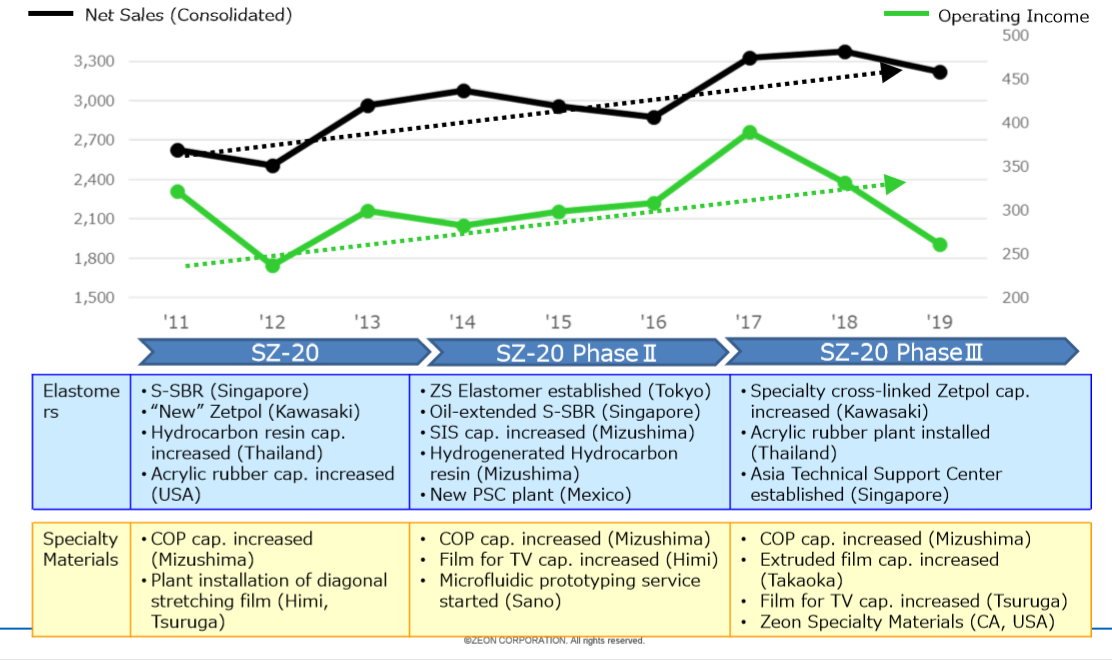

Progress of “Mid-term Management Plan SZ-20 Phase III” covering a four-year period beginning from fiscal year March 2018 is as follows.

(1) Groupwide Strategy

Growth | 1 | “Reinforce” the combined strengths of the Zeon group. “Explore” ways of going beyond boundaries and collaborating with external players to provide solutions globally as a contribution to society. |

2 | Accelerate the pace of new businesses creation and product development in “key development areas”: global environment, smart devices, and health and living. | |

Corporate Culture | 3 | Cultivate a corporate culture that places value on taking proactive action by harnessing diverse idea and trying them. |

As for the key development areas, the company applies for “global environment (e.g. energy conservation, automobile-related, power generation and storage)”, “health and living (e.g. self-driving cars, medical devices/materials, daily necessities)” and “smart devices (IoT-related),” which are estimated to have a high growth rate and probability of innovation.

◎Strategies by Business Segment

| Elastomer Business |

| Specialty Materials Business |

☆ | Reinforce competitive business by responding globally to growth markets and raising cost effectiveness. | ☆ | Expand business in step with the speed of market growth and technological progress through focused investment of resources and stronger collaboration with outside players. |

☆ | Explore new opportunities and achieve growth based on the trust built in the market and relationship with customers. |

Under the themes of “speed,” “dialogue,” and “social contribution,” the company fosters more mutual trust with its group members. As the way it wants to be in FY 2020, the company pursues “Zeon makes the future today with the power of chemistry” and aims to achieve consolidated sales of more than 500 billion yen.

(2) Performance of the entire company

① Overview

Sales hit a record high consecutively in the fiscal year March 2018 and the fiscal year March 2019 after entering SZ-20 Phase III. However, for the fiscal year March 2020, sales, and profit decreased because of the global economic slowdown.

Looking at each segment, sales of elastomers in the automotive industry and the general industry decelerated, which resulted in a decline in sales and profit. In contrast, for the specialty materials business, optical plastics, optical films, and battery materials performed well and hit a record high in sales and operating income.

Furthermore, the effects of the novel coronavirus were minor in the previous term; however, the company thinks that for this term a great impact is unavoidable.

② ROE

ROE, which is an important management indicator, has recovered to around 8% as there was no longer impairment loss of the Singapore subsidiary.

Regarding returns to stockholders, the company aims to provide stable and continuous dividends.

(3) 9 years of SZ-20 progress

Regarding “SZ-20” which started in the fiscal year March 2012, the company followed the policies and continuously made investments for the elastomers business and the specialty materials business, thanks to which the business grew.

Particularly, for the specialty materials business, the company focused on improving COP and achieved a record high in sales and operating income.

(4) Progress of phase III in each segment

① Elastomer Business

<Specialty Rubbers>

To cope with environmental issues, EVs and fuel-cell vehicles are expected to be distributed, but the sales volume of internal combustion engine vehicles is estimated to be at a certain level from the viewpoints of cost and efficiency.

The importance of specialty rubber, which is used in the automobile industry, will remain significant, and the company plans to support the industry by supplying it stably.

The sale of the specialty cross-linked type of Zetpol® is steadily growing.

As for acrylic rubber, the company’s annual production output at its 3 bases in Japan and the U.S. is 17,000 tons, and the Thai plant with a production capacity of 5,000 tons/year is to be completed in the spring of 2020.

Asia Technical Support Laboratory, which was established in 2017, continues customer support and related sales of Zeon’s rubbers.

➁ Specialty Material Business

<Investment Situation>

◎Optical Film

The company is increasing the production output of extruded films at Takaoka Plant, and the operation of the new production line is scheduled to be started in the spring of 2020. In addition, the company is constructing a new line for optical films for large-sized TV sets at Tsuruga Plant, and its operation is scheduled to be started in the first quarter of the fiscal year ending March 2021. Production output is 50 million m2 per year. Furthermore, the company is investing for enhancing the production output of COP at Mizushima Plant, and it is scheduled to be completed in July 2021. Annual production capacity is 4,600 tons. Thanks to these investments, the company expects that the production capacity of COP will increase to 41,600 tons/year in the fiscal year March 2022.

◎ Sales bases in the U.S.

As the company can respond to the market needs quicker after entering Silicon Valley, the hub of the IT industry; in October 2017, it established the specialty materials business base, “Zeon Specialty Materials Inc.,” and started operations in January 2018.

The operational activities are targeting the specialty plastics (cyclo olefin polymer), specialty parts (optical films), battery materials (binders for lithium-ion rechargeable batteries), and electronic materials (insulation material, resistance, and etching gas).

<Strengths of the Optical Film Business>

The company considers that this business has the following 4 strengths:

Strength | Outline |

Strength of the raw material | Applicability of dicyclopentadiene obtained with the original GPI method |

Strength of the plastics | Characteristics of the plastics synthesized from raw materials obtained with the GPI method, such as heat resistance, moisture resistance, and workability |

Strength of the processing technology | The melt extrusion and film stretching technology is unique to the company. |

Strength of the integrated production | With the integrated production, including polymer design, manufacturing, and processing, it is possible to reflect the needs in the market in polymer design swiftly. |

<Exploring medical devices and materials for the medical field>

In April 2020, the subsidiary, Zeon Medical Inc., decided to invest 500 million yen in the “MPI-2 Investment Limited Partnership,” a fund established by MedVenture Partners, which is a VC (Venture Capital) that specializes in medical devices investments.

Through this investment, the company plans to expand its business portfolio by utilizing opportunities to directly invest in venture businesses, collect information about the advanced medical technologies domestically and internationally, and discover cooperation opportunities with venture businesses.

6. Conclusions

It is currently difficult to predict the degree of COVID-19 effects, thus for the short-term, it is probably best to closely follow the reports of each quarter. As the economy recovers when the pandemic subsides, we will pay attention to how quickly the business can expand overseas, where regulations for going out are stricter than those in Japan.

<Reference: Regarding Corporate Governance>

◎ Organization type, and the composition of directors and auditors

Organization type | Company with an audit and supervisory board |

Directors | 10 directors, including 3 external ones |

Auditors | 5 auditors, including 3 external ones |

◎ Corporate Governance Report

Last update date: :July, 3, 2020

Basic policy

Our company respects the interests of a broad range of stakeholders, including shareholders, and aims to earn revenue and continuously improve our corporate value while adjusting the relations of interests. To do so, we will make continuous efforts to establish a system for realizing efficient, sound business administration through corporate governance.

In addition, we will make decisions and execute business operations swiftly after clarifying the functions and roles of each institution and each in-company organization by developing internal control systems. We will properly monitor and disclose its progress and results and strive to improve the transparency of our business administration.

Reasons for Non-compliance with the Principles of the Corporate Governance Code (Excerpts)

(All principles are stated based on the code before the revision in June 2018.)

Our company follows the principles of the corporate governance code.

Disclosure Based on the Principles of the Corporate Governance Code (Excerpts)

Principles | Disclosure content |

【Principle 1-4 The so-called strategically held shares】 | ・Before strategically holding shares of any other companies, we consider carefully if the strategically held shares of a company strengthen the relationship between us and our business partners, the society and other stakeholders and will eventually enhance our corporate value in a medium- to long-term perspective.

・As for shares held based on these considerations, the company will annually verify the appropriateness of holding shares of each company by considering the appropriateness of its holding purpose and whether the benefits, risks, etc. that come along are commensurate with the capital cost. Most recently, the Board of Directors made the verification in their meeting, which was held on October 31, 2018, and will decide whether to reduce shares of companies that are acknowledged to have lost their holding purpose.

・We will determine when to exercise our voting right of strategically held shares based on a medium- to long-term viewpoint on enhancement of the corporate value of the company that we invest in. |

Principle 5-1 Policy on constructive dialogue with shareholders | ・In our company, the Department of Corporate Communications is in charge of interacting with our shareholders, and the executive responsible for CSR manages the office. ・The Corporate Communication Dept. appropriately exchanges information with the Corporate Planning Dept., the Accounting & Finance Dept., the General Affairs Dept., the Legal Affairs Dept., etc. and provides precise and unbiased information to our shareholders. ・Our company will continuously strive to enrich methods of dialogue other than individual interviews, such as holding information sessions for investors on a quarterly basis, improving explanatory materials for our financial results disclosed on our website and participating in company information sessions for individual investors. ・The Corporate Communications Dept. collates and analyzes opinions obtained through interaction with our shareholders when necessary and report them to the Representative Director. ・Our company thoroughly manages unreleased important facts in accordance with the “Insider Trading and Timely Disclosure Management Rules”, and communicates with our shareholders to prevent information leak. |

This report is intended solely for information purposes and is not intended as a solicitation for investment. The information and opinions contained within this report are made by our company based on data made publicly available, and the information within this report comes from sources that we judge to be reliable. However, we cannot wholly guarantee the accuracy or completeness of the data. This report is not a guarantee of the accuracy, completeness, or validity of said information and opinions, nor do we bear any responsibility for the same. All rights pertaining to this report belong to Investment Bridge Co., Ltd., which may change the contents thereof at any time without prior notice. All investment decisions are the responsibility of the individual and should be made only after proper consideration. Copyright(C) 2020 Investment Bridge Co., Ltd. All Rights Reserved. |

For back numbers of Bridge Reports on ZEON CORPORATION(4205)and Bridge Salon (IR seminar), please go to our website at the following URL. www.bridge-salon.jp/

<Appendix:Fact Sheet>

|

|

|

<Major Shareholders>

Shareholder | Number of Holding Shares (thousand) | Rate (%) | ||

Yokohama Rubber Co., Ltd. | 22,682 |

| 10.38 |

|

The Master Trust Bank of Japan, Ltd. (Trust Account) | 10,922 |

| 5.00 |

|

Japan Trustee Services Bank, Ltd. (Trust Account) | 9,806 |

| 4.49 |

|

Mizuho Bank, Ltd | 9,600 |

| 4.39 |

|

National Mutual Insurance Federation of Agricultural | 7,700 |

| 3.52 |

|

Asahi Mutual Life Insurance Company | 7,679 |

| 3.51 |

|

Asahi Kasei Corporation | 6,438 |

| 2.95 |

|

BNY GCM CLIENT ACCOUNT JPRD AC ISG (FE-AC) | 5,921 |

| 2.71 |

|

The Norinchukin Bank | 4,000 |

| 1.83 |

|

Zeon Corporation Client Stock Ownership Association | 3,783 |

| 1.73 |

|

| 88,531 |

| 40.51 |

|

*Total number of shares issued at the end of the term common stock 237,075,556shares

As of Mar. 31, 2020

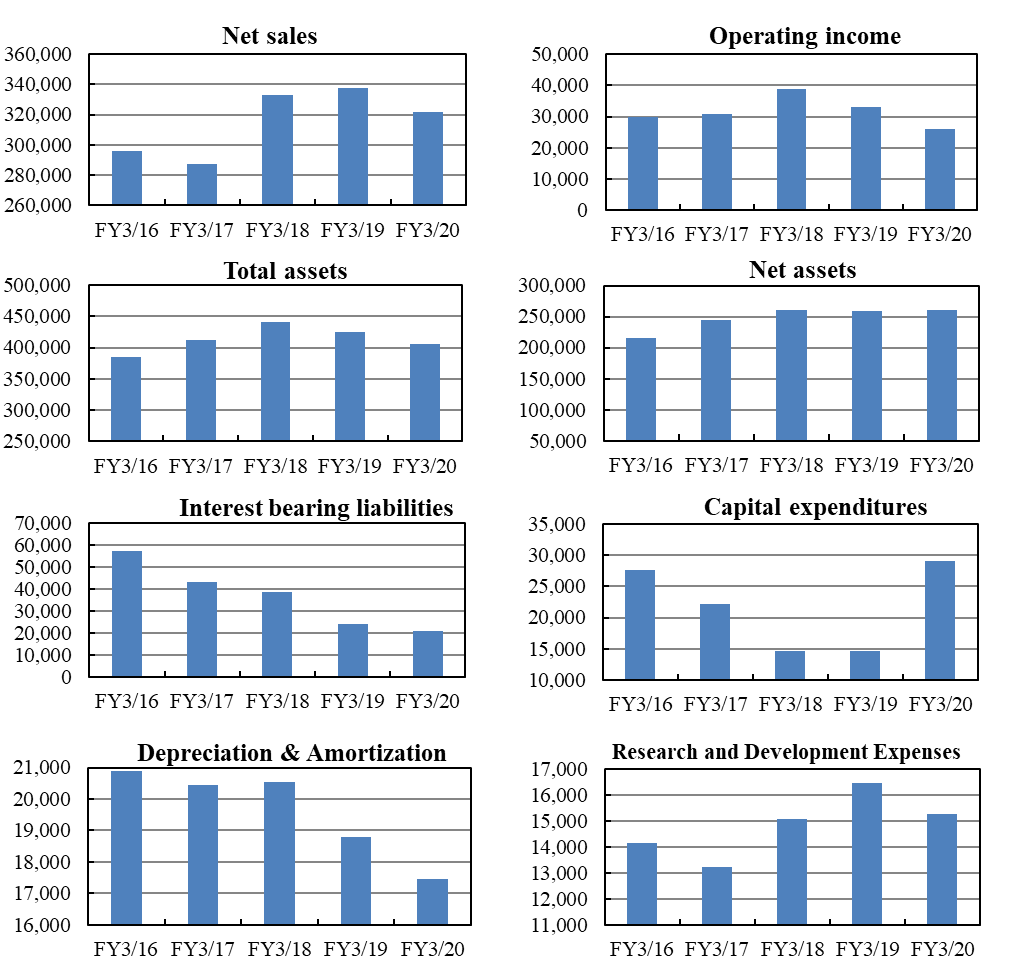

<Selected Financial Data>

| FY3/16 | FY3/17 | FY3/18 | FY3/19 | FY3/20 |

Net sales | 295,647 | 287,624 | 332,682 | 337,499 | 321,966 |

Gross profit | 87,187 | 86,925 | 101,272 | 96,742 | 91,911 |

Operating income | 29,856 | 30,767 | 38,881 | 33,147 | 26,104 |

Ordinary income | 32,153 | 31,805 | 40,893 | 36,319 | 28,744 |

Net income | 18,079 | 23,152 | 13,056 | 18,458 | 20,201 |

EPS (JPY) | 79.9 | 104.3 | 58.8 | 84.1 | 92.4 |

DPS (JPY) | 15.00 | 16.00 | 17.00 | 19.00 | 21.00 |

Total assets | 384,753 | 411,415 | 440,519 | 424,937 | 405,131 |

Net assets | 215,586 | 244,634 | 259,940 | 259,156 | 260,358 |

Interest bearing liabilities | 57,064 | 43,177 | 38,573 | 24,125 | 20,960 |

Capital expenditures | 27,650 | 22,122 | 14,568 | 14,640 | 29,088 |

Depreciation & Amortization &Amortization | 20,904 | 20,431 | 20,539 | 18,780 | 17,448 |

R&D Expenses | 14,148 | 13,233 | 15,103 | 16,480 | 15,274 |

(Units: Million Yen)

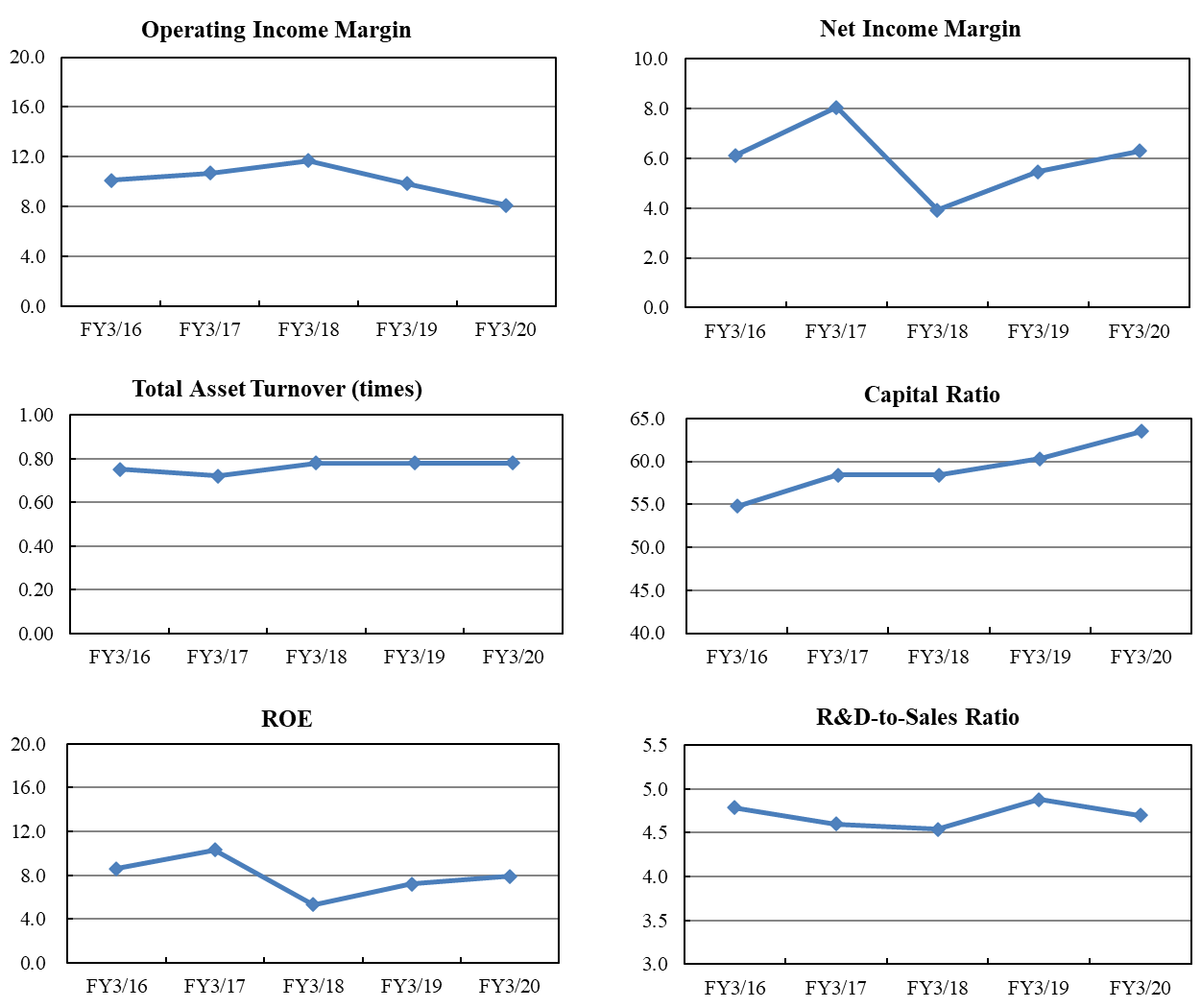

<Financial Summary>

| FY3/16 | FY3/17 | FY3/18 | FY3/19 | FY3/20 |

Operating Income Margin | 10.1 | 10.7 | 11.7 | 9.8 | 8.1 |

Net Income Margin | 6.1 | 8.0 | 3.9 | 5.5 | 6.3 |

Total Asset Turnover (times) | 0.82 | 0.72 | 0.78 | 0.78 | 0.78 |

Capital Ratio | 54.8 | 58.4 | 58.4 | 60.3 | 63.5 |

ROE | 8.6 | 10.3 | 5.3 | 7.2 | 7.9 |

R&D-to-Sales Ratio | 4.8 | 4.6 | 4.5 | 4.9 | 4.7 |

(Units: %)

<Segment Information>

| FY3/16 | FY3/17 | FY3/18 | FY3/19 | FY3/20 |

Sales |

|

|

|

|

|

Elastomer Business | 178,940 | 166,243 | 194,570 | 198,087 | 178,847 |

Specialty Material Business | 70,979 | 74,980 | 86,479 | 85,142 | 91,749 |

Others | 47,950 | 49,038 | 53,928 | 56,733 | 53,473 |

Eliminations and corporate assets | -2,222 | -2,637 | -2,295 | -2,463 | -2,103 |

Consolidated | 295,647 | 287,624 | 332,682 | 337,499 | 321,966 |

Operating income |

|

|

|

|

|

Elastomer Business | 20,725 | 20,552 | 22,169 | 17,691 | 9,642 |

Specialty Material Business | 8,221 | 9,832 | 16,742 | 16,115 | 17,311 |

Others | 2,503 | 2,865 | 3,206 | 2,786 | 2,098 |

Eliminations and corporate assets | -1,592 | -2,482 | -3,237 | -3,446 | -2,948 |

Consolidated | 29,856 | 30,767 | 38,881 | 33,147 | 26,104 |

Total assets |

|

|

|

|

|

Elastomer Business | 193,560 | 201,054 | 213,137 | 209,089 | 189,618 |

Specialty Material Business | 80,916 | 82,673 | 88,122 | 89,402 | 101,425 |

Others | 27,873 | 29,165 | 30,907 | 32,907 | 31,193 |

Eliminations and corporate assets | 82,404 | 98,523 | 108,353 | 93,539 | 82,895 |

Consolidated | 384,753 | 411,415 | 440,519 | 424,937 | 405,131 |

Depreciation & Amortization |

|

|

|

|

|

Elastomer Business | 9,693 | 9,929 | 10,208 | 8,864 | 8,432 |

Specialty Material Business | 8,569 | 7,845 | 7,781 | 6,793 | 6,089 |

Others | 316 | 353 | 326 | 302 | 312 |

Eliminations and corporate assets | 2,326 | 2,304 | 2,223 | 2,822 | 2,616 |

Consolidated | 20,904 | 20,431 | 20,539 | 18,780 | 17,448 |

Capital Expenditure |

|

|

|

|

|

Elastomer Business | 15,665 | 11,166 | 7,998 | 5,744 | 7,792 |

Specialty Material Business | 7,521 | 7,644 | 3,644 | 6,234 | 17,965 |

Others | 395 | 342 | 362 | 359 | 95 |

Eliminations and corporate assets | 4,069 | 2,971 | 2,564 | 2,303 | 3,236 |

Consolidated | 27,650 | 22,122 | 14,568 | 14,640 | 29,088 |

(Units: Million Yen)