| Nippon Piston Ring (6461) |

|

||||||||

Company |

Nippon Piston Ring Co., Ltd. |

||

Code No. |

6461 |

||

Exchange |

TSE First Section |

||

Industry |

Machinery (Manufacturing) |

||

President |

Akira Yamamoto |

||

HQ Address |

5-12-10, Honmachi Higashi, Chuo-ku, Saitama City, Saitama, Japan |

||

Year-end |

March |

||

URL |

|||

*The share price is the closing price on June 22, 2018. The number of shares outstanding was taken from the latest brief financial report.

ROE and BPS are the value for the previous term. |

||||||||||||||||||||||||

|

|

*The definition for net income is net income attributable to owners of parent (Hereinafter the same apply).

*EPS and DPS have been adjusted to reflect the reverse stock split of 1 for 10 conducted on October 1, 2015. *A commemorative dividend of ¥1.00 per share in addition to the normal dividend of ¥5.00 was conducted to commemorate the 80th year of Nippon Piston Ring's operations in FY 2014. *Estimates are those of the Company. The company plans to pay an interim dividend in FY 2018 (interim: 30.00 yen, year-end: 45.00 yen). |

| Key Points |

|

| Company Overview |

|

Nippon Piston Ring manufactures and sells piston rings and valve seat inserts which are important functional parts for automobile engines. The Company boasts of a market share just under 30% of piston rings and just under 40% of valve seat inserts supplied to Japanese automobile manufacturers. It supplies its products not only to all Japanese automobile manufacturers but also to many prominent non-Japanese automobile manufacturers.

Nippon Piston Ring boasts of strengths in metallic materials, surface quality improvement and precision processing technologies. Development of new products and business expansion to non-automobile engine parts realms such as METAMOLD (metal injection molding products) and medical products are being strengthened.

<Corporate History>

Nippon Piston Ring was founded by Tomonori Suzuki in 1931 in Kawaguchi City, Saitama Prefecture just prior to the start of mass domestic production of automobiles by manufacturers such as Toyota and Nissan, following the Government program for "establishment of an automobile industry" adopted in August 1935. The company name Nippon Piston Ring Co., Ltd. was officially adopted along with the establishment of the factory in Kawaguchi City in 1934.

During the Second World War, the Company began mass production of chrome plated piston rings for airplanes. At the end of the War in 1945, the factory was temporarily closed, but the company began operations along with the listing of its shares on the Tokyo Stock Exchange in 1949.

Nippon Piston Ring's earnings expanded rapidly along with the rapid expansion in Japanese automobile exports, and the strong demand for vehicles due to economic growth in the post-war reconstruction within Japan.

Beginning to provide products to German and American automobile manufacturers in the 1970s, the Company has continued organizing a global manufacturing and sales structure, establishing production bases in Thailand, Indonesia, United States, China and India since 2000.

The metal injection molding products business and dental implants business were acquired in 2014 as part of the strategy of expanding its product lineup outside of the automobile engine parts realm, and the Company has started to operate the business by its own facility since 2015.

<Corporate Philosophy>

<Market Environment>

◎Global Automobile Production Volume

The global production volume of vehicles of less than six tons in gross weight is expected to continue to increase from 95 million in 2017 to 116 million in 2030.

Looking at the details of these estimates, vehicles of less than six tons manufactured in Europe, North America, Japan and other developed economic regions are expected to see the same level. However, gradual growth in China, ASEAN countries, South America, India and other developing economic regions is expected to allow their share of vehicles of less than six tons to rise from 52% in 2017 to 54% in 2030. <Market Environment>

◎Global Automobile Production Volume

The global production volume of vehicles of less than six tons in gross weight is expected to continue to increase from 95 million in 2017 to 116 million in 2030.

Looking at the details of these estimates, vehicles of less than six tons manufactured in Europe, North America, Japan and other developed economic regions are expected to see the same level. However, gradual growth in China, ASEAN countries, South America, India and other developing economic regions is expected to allow their share of vehicles of less than six tons to rise from 52% in 2017 to 54% in 2030.

◎Production Volume by Powertrain (Drive System)

It is projected, regarding the production volume forecast by powertrain (drive system), that the growing environmental awareness will result in a reduction of gasoline and diesel engines, while the share of hybrid vehicles will increase, mainly in developing economic regions. Electric vehicles (EVs), which don't require engines, will account for only 7% in 2030, which means that demand for piston rings and valve seat inserts is expected to continue to show healthy growth. ◎Production Volume by Powertrain (Drive System)

It is projected, regarding the production volume forecast by powertrain (drive system), that the growing environmental awareness will result in a reduction of gasoline and diesel engines, while the share of hybrid vehicles will increase, mainly in developing economic regions. Electric vehicles (EVs), which don't require engines, will account for only 7% in 2030, which means that demand for piston rings and valve seat inserts is expected to continue to show healthy growth.

There are three publicly traded companies in Japan that manufacture piston rings, including Nippon Piston Ring, and these companies are operating other businesses respectively. Riken Corporation (6462) boasts of a top share of the piston ring market of close to 50%, but TPR Co., Ltd. (6463) boasts of much larger scale, earnings and market capitalization than the other two companies.

Although Nippon Piston Ring's market capitalization, PER and PBR are small and the stock price evaluation is low, an increase in operating income is estimated, and we would like to expect an upturn in the stock prices by further improving profitability.

<Business Description>

◎Main Products

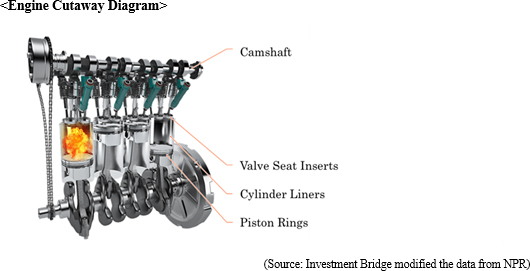

As reflected in the Company name, piston rings are one of the main products manufactured. In addition, valve seat inserts and various other automobile parts are manufactured and sold. In fiscal year 2017, automobile related parts accounted for 86.8% of total sales.

At the same time, development of new product and business expansion to non-automobile engine parts realms such as METAMOLD (metal injection molding products) and medical products including dental implant products, which were acquired in 2014 are being strengthened.

There are three publicly traded companies in Japan that manufacture piston rings, including Nippon Piston Ring, and these companies are operating other businesses respectively. Riken Corporation (6462) boasts of a top share of the piston ring market of close to 50%, but TPR Co., Ltd. (6463) boasts of much larger scale, earnings and market capitalization than the other two companies.

Although Nippon Piston Ring's market capitalization, PER and PBR are small and the stock price evaluation is low, an increase in operating income is estimated, and we would like to expect an upturn in the stock prices by further improving profitability.

<Business Description>

◎Main Products

As reflected in the Company name, piston rings are one of the main products manufactured. In addition, valve seat inserts and various other automobile parts are manufactured and sold. In fiscal year 2017, automobile related parts accounted for 86.8% of total sales.

At the same time, development of new product and business expansion to non-automobile engine parts realms such as METAMOLD (metal injection molding products) and medical products including dental implant products, which were acquired in 2014 are being strengthened.

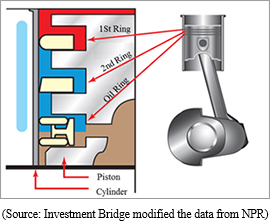

<Piston Rings> <Piston Rings>

Piston rings are fitted in grooves that run around the circumference of pistons and have spring-like characteristics to act as a seal for ideal combustion within the combustion chamber of the engine cylinders and control lubrication of the piston and cylinder walls by forming precise circles. Moreover, three piston rings are normally used, to form a seal to prevent leakage of oil, allow heat to escape and reduce both friction wear and baking.

Smooth movement of pistons will be impeded and fuel consumption will be negatively impacted should the tensional force of the piston ring placed on pistons be too high. Conversely, loss of power and increased oil consumption will result if the tensional force of the piston ring placed on pistons is too low

Consequently, optimization of the tensional forces of piston rings is crucial in ensuring the optimum performance of internal combustion piston engines.

An oil film is formed between the cylinder wall and pistons to reduce friction wear and baking, which could be caused by the high-speed movement of pistons within a high-heat condition of cylinders. However, it's not thicker the better; piston oil rings need to be designed to ensure that an optimal thickness of oil film is formed. Piston rings are fitted in grooves that run around the circumference of pistons and have spring-like characteristics to act as a seal for ideal combustion within the combustion chamber of the engine cylinders and control lubrication of the piston and cylinder walls by forming precise circles. Moreover, three piston rings are normally used, to form a seal to prevent leakage of oil, allow heat to escape and reduce both friction wear and baking.

Smooth movement of pistons will be impeded and fuel consumption will be negatively impacted should the tensional force of the piston ring placed on pistons be too high. Conversely, loss of power and increased oil consumption will result if the tensional force of the piston ring placed on pistons is too low

Consequently, optimization of the tensional forces of piston rings is crucial in ensuring the optimum performance of internal combustion piston engines.

An oil film is formed between the cylinder wall and pistons to reduce friction wear and baking, which could be caused by the high-speed movement of pistons within a high-heat condition of cylinders. However, it's not thicker the better; piston oil rings need to be designed to ensure that an optimal thickness of oil film is formed.

Piston rings are required to provide wear resistance, material strength, heat resistance, heat conductivity, and oil retention capacity to ensure the optimal performance and durability of engines.

In recent years, with the rapid rise in awareness of environment issues, a swift response is vital to adjust to a system that certifies vehicles with low output levels of nitrous oxides and hydrocarbons, and regulations to enforce reductions in a carbon dioxide emission. Consequently, the need for high-performance piston rings that respond to these developments and the need for improvements in fuel consumption are on the rise.

With regards to the characteristics required to piston rings, development of piston rings with low friction construction, thinner width, new surface treatment processes, highly durable and low-cost materials is being conducted. At the same time, development and proposal of optimal design technologies using its tuning technic are also being promoted.

Nippon Piston Ring is one of only few companies that have the ability to stably manufacture and supply piston rings, which, as you may see, require extremely advanced technological capabilities, and are able to consistently develop revolutionary technologies.

<Valve Seat Inserts> Piston rings are required to provide wear resistance, material strength, heat resistance, heat conductivity, and oil retention capacity to ensure the optimal performance and durability of engines.

In recent years, with the rapid rise in awareness of environment issues, a swift response is vital to adjust to a system that certifies vehicles with low output levels of nitrous oxides and hydrocarbons, and regulations to enforce reductions in a carbon dioxide emission. Consequently, the need for high-performance piston rings that respond to these developments and the need for improvements in fuel consumption are on the rise.

With regards to the characteristics required to piston rings, development of piston rings with low friction construction, thinner width, new surface treatment processes, highly durable and low-cost materials is being conducted. At the same time, development and proposal of optimal design technologies using its tuning technic are also being promoted.

Nippon Piston Ring is one of only few companies that have the ability to stably manufacture and supply piston rings, which, as you may see, require extremely advanced technological capabilities, and are able to consistently develop revolutionary technologies.

<Valve Seat Inserts>

Valve seat inserts are parts which are press-fitted into the valve seating portion of cylinder heads. Valve seat inserts are a very important part made from sintered alloys that boast of high resistance to wear and deterioration under high heat conditions and ensure that a tight seal is formed for clean and efficient combustion. Nippon Piston Ring boasts of quality valve seat inserts that meet the needs of automobile manufacturers at a high level, using a wide range of material variation, leveraging its superior materials development capabilities. Consequently, the Company boasts of a top share of slightly less than 40% of valve seat inserts provided to Japanese automobile manufacturers and it is further expanding its sales to both Japanese and overseas motor vehicle manufacturers.

<Camshafts> Valve seat inserts are parts which are press-fitted into the valve seating portion of cylinder heads. Valve seat inserts are a very important part made from sintered alloys that boast of high resistance to wear and deterioration under high heat conditions and ensure that a tight seal is formed for clean and efficient combustion. Nippon Piston Ring boasts of quality valve seat inserts that meet the needs of automobile manufacturers at a high level, using a wide range of material variation, leveraging its superior materials development capabilities. Consequently, the Company boasts of a top share of slightly less than 40% of valve seat inserts provided to Japanese automobile manufacturers and it is further expanding its sales to both Japanese and overseas motor vehicle manufacturers.

<Camshafts>

Camshafts are a part designed to open and close the valves for each cylinder in piston engines. Nippon Piston Ring has the original technology for a special camshaft called assembled sintered camshafts, which are lightweight, highly resistant to contact pressure and capable of adopting a wide variety of designs. They are used by SUBARU in all of its self-manufactured engines, as well as used by truck manufacturers, which require highly durable products.

<METAMOLD (Metal injection molding products)> Camshafts are a part designed to open and close the valves for each cylinder in piston engines. Nippon Piston Ring has the original technology for a special camshaft called assembled sintered camshafts, which are lightweight, highly resistant to contact pressure and capable of adopting a wide variety of designs. They are used by SUBARU in all of its self-manufactured engines, as well as used by truck manufacturers, which require highly durable products.

<METAMOLD (Metal injection molding products)>

In recent years, various processing technologies and methods, including machine processing, precision casting (lost wax), die casting, and press sintering, have been selected and used for molding metallic parts based on functions and costs required for parts. "METAMOLD," which was developed as a completely new 5th-generation processing technology, is a resource-saving and energy-saving technology that was developed based on the metallurgical technology that the company has cultived over years. It has made it possible to manufacture the same complicated shape as plastic products and die-cast products. The company has expanded the lineup of product groups by strengthening its material and manufacturing technology and expanded its business to not only automobile engine parts but also non-automobile engine parts including industrial mahcinery and office automation parts. Especially, demand for circulation piece for ball screws is increasing.

◎Customers

Nippon Piston Ring supplies piston rings and valve seat inserts to all Japanese automobile manufacturers.

The products supplied by the Company are extremely important in improving the performance of engines and require high levels of technical expertise. In recent years, the need to improve fuel consumption and to seek alternative fuels due to the growing importance of environmental issues has contributed to expanded sales to non-Japanese automobile manufacturers such as European, American and Chinese local automobile manufacturers. In recent years, various processing technologies and methods, including machine processing, precision casting (lost wax), die casting, and press sintering, have been selected and used for molding metallic parts based on functions and costs required for parts. "METAMOLD," which was developed as a completely new 5th-generation processing technology, is a resource-saving and energy-saving technology that was developed based on the metallurgical technology that the company has cultived over years. It has made it possible to manufacture the same complicated shape as plastic products and die-cast products. The company has expanded the lineup of product groups by strengthening its material and manufacturing technology and expanded its business to not only automobile engine parts but also non-automobile engine parts including industrial mahcinery and office automation parts. Especially, demand for circulation piece for ball screws is increasing.

◎Customers

Nippon Piston Ring supplies piston rings and valve seat inserts to all Japanese automobile manufacturers.

The products supplied by the Company are extremely important in improving the performance of engines and require high levels of technical expertise. In recent years, the need to improve fuel consumption and to seek alternative fuels due to the growing importance of environmental issues has contributed to expanded sales to non-Japanese automobile manufacturers such as European, American and Chinese local automobile manufacturers.

<Production and Sales Bases>

<Japan>

Nippon Piston Ring maintains four production bases and seven sales bases (Tokyo [head office: Saitama City], Nagoya, Osaka, Hiroshima, Fukuoka, Sendai, Sapporo) within Japan. <Production and Sales Bases>

<Japan>

Nippon Piston Ring maintains four production bases and seven sales bases (Tokyo [head office: Saitama City], Nagoya, Osaka, Hiroshima, Fukuoka, Sendai, Sapporo) within Japan.

<Overseas>

Nippon Piston Ring maintains both manufacturing and sales bases for piston rings, valve seat inserts and other products in the United States, China, ASEAN countries, and India. The company has sales bases in Germany, Singapore and Malaysia , too. <Overseas>

Nippon Piston Ring maintains both manufacturing and sales bases for piston rings, valve seat inserts and other products in the United States, China, ASEAN countries, and India. The company has sales bases in Germany, Singapore and Malaysia , too.

<Characteristics and Strengths>

Nippon Piston Ring's highly advanced technologies and ability to consistently supply highly reliable functional automobile parts maintained throughout its history over 80 years of operations has allowed it to become the choice of both Japanese and overseas automobile manufacturers. In recent years, development of major products, which can contribute to reductions in exhaust gases, low output levels of carbon dioxides and the achievement of "over 50% thermal efficiency rates" in internal combustion engines, is being conducted.

Nippon Piston Ring's Three Main Technology Categories <Characteristics and Strengths>

Nippon Piston Ring's highly advanced technologies and ability to consistently supply highly reliable functional automobile parts maintained throughout its history over 80 years of operations has allowed it to become the choice of both Japanese and overseas automobile manufacturers. In recent years, development of major products, which can contribute to reductions in exhaust gases, low output levels of carbon dioxides and the achievement of "over 50% thermal efficiency rates" in internal combustion engines, is being conducted.

Nippon Piston Ring's Three Main Technology Categories

With regards to product development, the ability to combine the said technologies and its simulation technologies applied to engines is one of Nippon Piston Ring's strengths.

In addition, automobile manufacturers, to whose business the Company's high levels of technological expertise are critical, are what the Company calls its "client assets," which are an important part of its corporate value.

With regards to product development, the ability to combine the said technologies and its simulation technologies applied to engines is one of Nippon Piston Ring's strengths.

In addition, automobile manufacturers, to whose business the Company's high levels of technological expertise are critical, are what the Company calls its "client assets," which are an important part of its corporate value.

ROE decreased 0.8% between fiscal year 2016 and fiscal year 2017. Despite a rise in total asset turnover, net profit margin and leverage declined. We would like to expect ROE to grow, as profitability improves.

ROE decreased 0.8% between fiscal year 2016 and fiscal year 2017. Despite a rise in total asset turnover, net profit margin and leverage declined. We would like to expect ROE to grow, as profitability improves.

|

| Fiscal Year 2017 Earnings Overview |

Sales and income increased. Sales and ordinary income marked record highs.

Sales increased 3.8 billion yen to 55.9 billion yen, up 7.3% year on year, hitting a record high. By product, piston rings increased 3 billion yen, up 12.1% year on year, driving the increase in sales.

Domestic sales increased 1.6 billion yen to 24.0 billion yen, up 7.2% year on year. Overseas sales increased 2.2 billion yen to 31.9 billion yen, up 7.4% year on year. Overseas sales ratio was 57.0%.

Operating income was 3.89 billion yen, up 20.2% year on year. An increase in personnel expenses and a rise in raw material costs were offset by the effect of increased production and cost reduction.

Ordinary income was 4.189 billion yen, up 44.5% year on year, marking a record high. Loss on foreign exchange in the previous fiscal year turned to gain on foreign exchange.

Net income was 2.286 billion yen, down 5.3% year on year due to temporary increase in deferred income tax adjustments and extraordinary losses.

In the second quarter (July-September), sales increased but operating income decreased compared with the same quarter of the previous year. However, as a result of identifying the issues and taking countermeasures, both sales and income increased in the second half as well as both the third and fourth quarters. Sales and income increased. Sales and ordinary income marked record highs.

Sales increased 3.8 billion yen to 55.9 billion yen, up 7.3% year on year, hitting a record high. By product, piston rings increased 3 billion yen, up 12.1% year on year, driving the increase in sales.

Domestic sales increased 1.6 billion yen to 24.0 billion yen, up 7.2% year on year. Overseas sales increased 2.2 billion yen to 31.9 billion yen, up 7.4% year on year. Overseas sales ratio was 57.0%.

Operating income was 3.89 billion yen, up 20.2% year on year. An increase in personnel expenses and a rise in raw material costs were offset by the effect of increased production and cost reduction.

Ordinary income was 4.189 billion yen, up 44.5% year on year, marking a record high. Loss on foreign exchange in the previous fiscal year turned to gain on foreign exchange.

Net income was 2.286 billion yen, down 5.3% year on year due to temporary increase in deferred income tax adjustments and extraordinary losses.

In the second quarter (July-September), sales increased but operating income decreased compared with the same quarter of the previous year. However, as a result of identifying the issues and taking countermeasures, both sales and income increased in the second half as well as both the third and fourth quarters.

Note: Product classification was changed from the past reports. (The classification for piston rings for marine engine that were included in "Piston Ring" were reviewed and moved to "Others." In addition, "METAMOLD (Metal injection molding products)," which was previously included in "Others" is now separately shown because its importance has increased.)

Sales of piston rings increased 12.1% year on year, and the composition ratio became 49% as a result of strong sales especially in China and ASEAN countries. Sales of the valve seat inserts and assembled sintered camshafts were also steady. Sales of METAMOLD, which was acquired from another company in fiscal year 2014, increased 18.3% year on year due to acquiring new customers.

Note: Product classification was changed from the past reports. (The classification for piston rings for marine engine that were included in "Piston Ring" were reviewed and moved to "Others." In addition, "METAMOLD (Metal injection molding products)," which was previously included in "Others" is now separately shown because its importance has increased.)

Sales of piston rings increased 12.1% year on year, and the composition ratio became 49% as a result of strong sales especially in China and ASEAN countries. Sales of the valve seat inserts and assembled sintered camshafts were also steady. Sales of METAMOLD, which was acquired from another company in fiscal year 2014, increased 18.3% year on year due to acquiring new customers.

Current assets grew 2.1 billion yen from the end of the previous term due to the increase in trade receivables. Non-current assets shrank 2.7 billion yen from the end of the previous term due to recording of impairment losses and establishment of retirement benefit trust. Accordingly, total assets were 66.5 billion yen, down 0.6 billion yen from the end of the previous term.

Total liabilities were 34 billion yen, down 2.2 billion yen from the end of the previous term due to reduction in interest-bearing debts and retirement benefit liability. Total interest-bearing debts were 16.4 billion yen, down 0.5 billion yen from the end of the previous term.

Net assets increased 1.6 billion yen from the end of the previous term to 32.4 billion yen due to an increase in retained earnings.

As a result, equity ratio rose 2.6% to 47.8% from the end of the previous term.

Interest-bearing debt, net interest-bearing debt and net Debt/Equity ratio fell below those at the end of the previous term.

Current assets grew 2.1 billion yen from the end of the previous term due to the increase in trade receivables. Non-current assets shrank 2.7 billion yen from the end of the previous term due to recording of impairment losses and establishment of retirement benefit trust. Accordingly, total assets were 66.5 billion yen, down 0.6 billion yen from the end of the previous term.

Total liabilities were 34 billion yen, down 2.2 billion yen from the end of the previous term due to reduction in interest-bearing debts and retirement benefit liability. Total interest-bearing debts were 16.4 billion yen, down 0.5 billion yen from the end of the previous term.

Net assets increased 1.6 billion yen from the end of the previous term to 32.4 billion yen due to an increase in retained earnings.

As a result, equity ratio rose 2.6% to 47.8% from the end of the previous term.

Interest-bearing debt, net interest-bearing debt and net Debt/Equity ratio fell below those at the end of the previous term.

The surplus of operating CF became smaller because loss on foreign exchange turned to gain, and retirement benefit trust set gain was recorded. The negative amount of investing CF became smaller due to decrease in purchase of property, plant and equipment.

The negative amount of financing CF increased due to a decrease in short-term borrowings. The cash position improved.

(4) Topics

◎The company received the "Quality Control Excellence Award" from Toyota Motor Corporation.

The surplus of operating CF became smaller because loss on foreign exchange turned to gain, and retirement benefit trust set gain was recorded. The negative amount of investing CF became smaller due to decrease in purchase of property, plant and equipment.

The negative amount of financing CF increased due to a decrease in short-term borrowings. The cash position improved.

(4) Topics

◎The company received the "Quality Control Excellence Award" from Toyota Motor Corporation.

The company is working on the N-ZD movement (NPR Zero Defect movement)* with the aim of raising awareness on quality among the employees. The performance of its global efforts was recognized, and it received the "Quality Control Excellence Award" from Toyota Motor Corporation.

*The N-ZD movement (NPR Zero Defect movement) is a campaign that the company launched in fiscal year 2015, which was the first year of the Sixth Mid-Term Business Plan, with the aim of systemizing quality improvement activities in order to not only improve customer satisfaction but also ensure the safety and security of the end user. This campaign is implemented in all processes from development to delivery to customers, aiming at improving work quality and product quality as well as reforming all employees' awareness on quality.

The company will continue the campaign in the Seventh Mid-Term Business Plan and pursue the "World's Highest Quality." The company is working on the N-ZD movement (NPR Zero Defect movement)* with the aim of raising awareness on quality among the employees. The performance of its global efforts was recognized, and it received the "Quality Control Excellence Award" from Toyota Motor Corporation.

*The N-ZD movement (NPR Zero Defect movement) is a campaign that the company launched in fiscal year 2015, which was the first year of the Sixth Mid-Term Business Plan, with the aim of systemizing quality improvement activities in order to not only improve customer satisfaction but also ensure the safety and security of the end user. This campaign is implemented in all processes from development to delivery to customers, aiming at improving work quality and product quality as well as reforming all employees' awareness on quality.

The company will continue the campaign in the Seventh Mid-Term Business Plan and pursue the "World's Highest Quality."

|

| Fiscal Year 2018 Earnings Forecast |

Sales and income will increase.

Sales are estimated to be 57.0 billion yen, up 1.9% year on year. Although domestic sales will decrease 1.7% year on year, overseas sales will be up 4.6% year on year and pull up the total sales.

Overseas sales ratio will rise to 58.5%. The foreign exchange rates are assumed to be 105 yen/US dollar and 128 yen/euro.

Operating income is forecasted to be 4.1 billion yen, up 5.4% year on year. The company will offset a rise in raw material cost, increase in personnel expenses, and unit price fluctuation by the effect of cost reduction and increased production.

Ordinary income is estimated to be 4.1 billion yen, down 2.1% year on year due to decrease of gain on foreign exchange. Net income is estimated to be 2.4 billion yen, up 5.0% year on year.

In order to improve opportunities for returning profits to shareholders, the company decided to begin payment of interim dividends (Record date: September 30, 2018) from this fiscal year.

The dividend amount is projected to be a total of 75 yen/share (30 yen for the interim and 45 yen for the year-end), up 5 yen from the previous year. Payout ratio is estimated to be 25.7%. Sales and income will increase.

Sales are estimated to be 57.0 billion yen, up 1.9% year on year. Although domestic sales will decrease 1.7% year on year, overseas sales will be up 4.6% year on year and pull up the total sales.

Overseas sales ratio will rise to 58.5%. The foreign exchange rates are assumed to be 105 yen/US dollar and 128 yen/euro.

Operating income is forecasted to be 4.1 billion yen, up 5.4% year on year. The company will offset a rise in raw material cost, increase in personnel expenses, and unit price fluctuation by the effect of cost reduction and increased production.

Ordinary income is estimated to be 4.1 billion yen, down 2.1% year on year due to decrease of gain on foreign exchange. Net income is estimated to be 2.4 billion yen, up 5.0% year on year.

In order to improve opportunities for returning profits to shareholders, the company decided to begin payment of interim dividends (Record date: September 30, 2018) from this fiscal year.

The dividend amount is projected to be a total of 75 yen/share (30 yen for the interim and 45 yen for the year-end), up 5 yen from the previous year. Payout ratio is estimated to be 25.7%.

|

| Summary of the Sixth Mid-Term Business Plan and Overview of the Seventh Mid-Term Business Plan |

The target values for fiscal year 2017 were "Net Sales of 55.0 billion yen or more, and Operating Margin of 7% or more." The company reached the target values as actual sales were 55.9 billion yen and the operating margin was 7.0%.

The target values for fiscal year 2017 were "Net Sales of 55.0 billion yen or more, and Operating Margin of 7% or more." The company reached the target values as actual sales were 55.9 billion yen and the operating margin was 7.0%.

The company made capital investment mainly to increase production capacity, and the amount of investment totaled 14.4 billion yen for 3 years of the Sixth Mid-Term Business Plan. In addition, by making investment to streamline such as innovative production lines, the company raised the production efficiency and improved profitability.

(2) Overview of the Seventh Mid-Term Business Plan (FY 2018 to FY 2020)

The basic policy, main initiatives and targets of the Seventh Mid-Term Business Plan, which is the 3-year plan starting this fiscal year, are as follows:

The company made capital investment mainly to increase production capacity, and the amount of investment totaled 14.4 billion yen for 3 years of the Sixth Mid-Term Business Plan. In addition, by making investment to streamline such as innovative production lines, the company raised the production efficiency and improved profitability.

(2) Overview of the Seventh Mid-Term Business Plan (FY 2018 to FY 2020)

The basic policy, main initiatives and targets of the Seventh Mid-Term Business Plan, which is the 3-year plan starting this fiscal year, are as follows:

The foreign exchange rates are set at 105 yen/US dollar and 128 yen/euro, and the net sales target for fiscal year 2020 is set at 58.0 billion yen or more. In addition, the target of overseas sales ratio is 61%, and sales to non-Japanese automobile manufacturers are expected to increase. Regarding profit, the company aims to achieve an operating margin of 7.5% or more by promoting cost reduction activities including innovative manufacturing.

The foreign exchange rates are set at 105 yen/US dollar and 128 yen/euro, and the net sales target for fiscal year 2020 is set at 58.0 billion yen or more. In addition, the target of overseas sales ratio is 61%, and sales to non-Japanese automobile manufacturers are expected to increase. Regarding profit, the company aims to achieve an operating margin of 7.5% or more by promoting cost reduction activities including innovative manufacturing.

The sales ratio of piston ring and valve seat insert, which are the company's core products and are sold globally, to non-Japanese automobile manufacturers will continue to increase. In addition, sales of METAMOLD other than automobile engine parts will also expand.

The sales ratio of piston ring and valve seat insert, which are the company's core products and are sold globally, to non-Japanese automobile manufacturers will continue to increase. In addition, sales of METAMOLD other than automobile engine parts will also expand.

Capital investment will be focused on increase production capacity, and maintenance & renewal, streamlining.

Capital investment will be focused on increase production capacity, and maintenance & renewal, streamlining.

The production capacity of piston rings in fiscal year 2020 will be further expanded at all production bases compared with fiscal year 2017, and that of valve seat inserts will increase in Japan, India and Thailand.

The production capacity of piston rings in fiscal year 2020 will be further expanded at all production bases compared with fiscal year 2017, and that of valve seat inserts will increase in Japan, India and Thailand.

|

| Interview with President Yamamoto |

|

We asked President Yamamoto about the review of the Sixth Mid-Term Business Plan and points of the Seventh Mid-Term Business Plan.

Q: "What is your self-assessment of the Sixth Mid-Term Business Plan?"

A: "The fact that both sales and operating margin could reach the target values has given us great confidence."

Although it would have been better if we could achieve slightly higher numbers than the targets of the Sixth Mid-Term Business Plan, namely, "Net Sales of 55.0 billion yen or more and Operating Margin of 7% or more," the fact that we gained the capacity to reach the target values in this 3-years has given us great confidence as a company.

Regarding sales, we managed to expand sales to non-Japanese automobile manufacturers beyond anticipation, partially because we have been blessed with a business environment that is characterized by a steady automobile market but also because we were able to enhance price competitiveness and promoted the "sales that is oriented to making and using technical proposals" while product specifications are becoming more sophisticated, and our customers recognized our superb quality.

Regarding operating margin, although it fell largely below the target in the first half of fiscal year 2017, we could recover in the second half. We believe this is because our cost reduction efforts we have been making at each factory have resulted in improved profitability. Meanwhile, we still have issues to be solved, so we will address them in the current Mid-Term Business Plan.

Also, we posted an impairment loss as an extraordinary loss. This is to immediately take measures to take care of unprofitable business. We will continue to improve our profitability in the future.

Q: "Next, please tell us about the progress of main initiatives."

A: "As for acquiring strategic models through differentiation of products and promotion of innovative manufacturing, we received high recognition from our customers and managed to produce results."

Acquiring strategic models through differentiation of products

We accurately grasped our customers' needs and seeds of the target strategic models. Furthermore, not only our sales department but also our development department visited customers, proposed the optimum product specification with technical back-up and convinced the customers. Furthermore, by showing customers our manufacturing process, we also gave them opportunities to understand that we can stably provide products.

With these efforts, our customers recognized the differentiation of not only specifications but also our efforts as a total. It can be said that we managed to promote differentiation of products.

I believe that receiving the excellence award related to quality from our major customer is because not only our product quality but also the overall activities of our company were highly appreciated, and I am very happy about it. Acquiring strategic models through differentiation of products

We accurately grasped our customers' needs and seeds of the target strategic models. Furthermore, not only our sales department but also our development department visited customers, proposed the optimum product specification with technical back-up and convinced the customers. Furthermore, by showing customers our manufacturing process, we also gave them opportunities to understand that we can stably provide products.

With these efforts, our customers recognized the differentiation of not only specifications but also our efforts as a total. It can be said that we managed to promote differentiation of products.

I believe that receiving the excellence award related to quality from our major customer is because not only our product quality but also the overall activities of our company were highly appreciated, and I am very happy about it.

Promoting innovative manufacturing

We began operation of the innovative manufacturing lines for piston rings and valve seat inserts. From the viewpoint of improving product quality, we could leave certain results, but some challenges remain from the cost reduction perspective.

In the Seventh Mid-Term Business Plan, the main challenge is striving for innovative manufacturing that contributes to cost reduction. Promoting innovative manufacturing

We began operation of the innovative manufacturing lines for piston rings and valve seat inserts. From the viewpoint of improving product quality, we could leave certain results, but some challenges remain from the cost reduction perspective.

In the Seventh Mid-Term Business Plan, the main challenge is striving for innovative manufacturing that contributes to cost reduction.

Commercialization of new products (Non-automobile engine parts)

The METAMOLD is spreading to the field of non-automobile engine parts, leading to the acquisition of new customers.

Regarding the medical field such as dental implants, we are aware that it will take some time to commercialize the business, but, by continuing marketing activities, we managed to seize opportunities that will lead to the future.

Q: "Next, please explain the focus point of the Seventh Mid-Term Business Plan."

A: "First of all, how to firmly build the business foundation of the existing businesses is the point. We think the most important thing to promote the basic policy and five main initiatives is `cultivating human resources'."

We believe that how to firmly build a business foundation of our existing products and METAMOLD is a key point. We purposely did not make drastic changes in the 5 main initiatives (Increase sales that is oriented to making and using technical proposals, both domestically and abroad, Strive for innovative manufacturing, Strengthen new product development, Strive for the world's highest quality, by strengthening human resources development, Continue to promote Corporate Social Responsibility activities) from the previous Mid-Term Business Plan, and to achieve further growth, we placed "manufacturing that adapts well to change" as a keyword of the basic policy. This means that we will respond flexibly to changes in the market or the order-receiving environment from a medium- to long-term perspective and create a constitution that can create profits under any circumstances.

As I mentioned earlier, during the current Mid-Term Business Plan, we will further pursue the cost reduction measures that we had set as a challenge in the previous Plan.

Furthermore, we believe that the most important action to promote the basic policy and five main initiatives is in "cultivating human resources." In addition to continuing various education programs and the development of human resources through the "NPR Internal College for Manufacturing," we will also focus on the development of human resources in overseas fields, whose importance will further increase as a pillar of our profit.

Specifically, we have set up opportunities for executive candidates who are in their 30s in overseas bases to learn about manufacturing at our factories in Japan, and we will continue to increase the number of participants in the future.

As for Japanese employees, we dispatch sales personnel and sales engineers (SEs) in their 20s and 30s to overseas language training to acquire English-language skills so that they can conduct sales that is oriented to making and using technical proposals to automobile manufacturers in Europe and the U.S. In addition, we would like to increase opportunities to contact with customers for SEs who are posted overseas so that we can proactively make technical proposals at an early stage.

Q: "Finally, please give messages to the shareholders and investors."

A: "We believe that our mission is to improve corporate value from a mid- to long-term perspective in order to ensure stable and continuous dividends growth. We would like to ask for your continuous support."

We were able to reach the numerical targets of the Sixth Mid-Term Business Plan, although they were at a minimum level. This made us possible to return profits to shareholders by steadily and continuously increasing dividends. We also believe that our mission is to continue to improve corporate value from a mid- to long-term perspective.

In the long term, the environment surrounding the automobile industry may change drastically, but we will continue to develop measures to address such risks. We would like to ask for your continuous support. Commercialization of new products (Non-automobile engine parts)

The METAMOLD is spreading to the field of non-automobile engine parts, leading to the acquisition of new customers.

Regarding the medical field such as dental implants, we are aware that it will take some time to commercialize the business, but, by continuing marketing activities, we managed to seize opportunities that will lead to the future.

Q: "Next, please explain the focus point of the Seventh Mid-Term Business Plan."

A: "First of all, how to firmly build the business foundation of the existing businesses is the point. We think the most important thing to promote the basic policy and five main initiatives is `cultivating human resources'."

We believe that how to firmly build a business foundation of our existing products and METAMOLD is a key point. We purposely did not make drastic changes in the 5 main initiatives (Increase sales that is oriented to making and using technical proposals, both domestically and abroad, Strive for innovative manufacturing, Strengthen new product development, Strive for the world's highest quality, by strengthening human resources development, Continue to promote Corporate Social Responsibility activities) from the previous Mid-Term Business Plan, and to achieve further growth, we placed "manufacturing that adapts well to change" as a keyword of the basic policy. This means that we will respond flexibly to changes in the market or the order-receiving environment from a medium- to long-term perspective and create a constitution that can create profits under any circumstances.

As I mentioned earlier, during the current Mid-Term Business Plan, we will further pursue the cost reduction measures that we had set as a challenge in the previous Plan.

Furthermore, we believe that the most important action to promote the basic policy and five main initiatives is in "cultivating human resources." In addition to continuing various education programs and the development of human resources through the "NPR Internal College for Manufacturing," we will also focus on the development of human resources in overseas fields, whose importance will further increase as a pillar of our profit.

Specifically, we have set up opportunities for executive candidates who are in their 30s in overseas bases to learn about manufacturing at our factories in Japan, and we will continue to increase the number of participants in the future.

As for Japanese employees, we dispatch sales personnel and sales engineers (SEs) in their 20s and 30s to overseas language training to acquire English-language skills so that they can conduct sales that is oriented to making and using technical proposals to automobile manufacturers in Europe and the U.S. In addition, we would like to increase opportunities to contact with customers for SEs who are posted overseas so that we can proactively make technical proposals at an early stage.

Q: "Finally, please give messages to the shareholders and investors."

A: "We believe that our mission is to improve corporate value from a mid- to long-term perspective in order to ensure stable and continuous dividends growth. We would like to ask for your continuous support."

We were able to reach the numerical targets of the Sixth Mid-Term Business Plan, although they were at a minimum level. This made us possible to return profits to shareholders by steadily and continuously increasing dividends. We also believe that our mission is to continue to improve corporate value from a mid- to long-term perspective.

In the long term, the environment surrounding the automobile industry may change drastically, but we will continue to develop measures to address such risks. We would like to ask for your continuous support.

|

| Conclusions |

|

In the second quarter of fiscal year 2017 (July - September), despite an increase in sales by 4.3%, compared with the same quarter of the previous year, operating income decreased 17.8%. However, both sales and income solidly recovered in the second half, and the company managed to reach the targets of the previous Mid-Term Business Plan. It seems that, as President Yamamoto mentioned in the interview, this has given the company great confidence.

The main initiatives of Seventh Mid-Term Business Plan are almost the same as the previous one, and we will continue to watch the overseas sales ratio, expansion of sales to non-Japanese automobile manufacturers, and growth in the field of non-automobile parts.

|

| <Reference: Corporate Governance> |

◎Corporate Governance Report

Last modified: June 27, 2018. ◎Corporate Governance Report

Last modified: June 27, 2018.

The company appreciates the need for foreign investors to understand the business models better and continues to plan to proceed with more active publishing in English.

The company appreciates the need for foreign investors to understand the business models better and continues to plan to proceed with more active publishing in English.

Disclaimer

This report is intended solely for information purposes, and is not intended as a solicitation for investment. The information and opinions contained within this report are made by our company based on data made publicly available, and the information within this report comes from sources that we judge to be reliable. However we cannot wholly guarantee the accuracy or completeness of the data. This report is not a guarantee of the accuracy, completeness or validity of said information and opinions, nor do we bear any responsibility for the same. All rights pertaining to this report belong to Investment Bridge Co., Ltd., which may change the contents thereof at any time without prior notice. All investment decisions are the responsibility of the individual and should be made only after proper consideration.Copyright (C) 2018 Investment Bridge Co., Ltd. All Rights Reserved. |