Bridge Report:(1433)BESTERRA the fiscal year January 2020

President Yoshihide Yoshino | BESTERRA CO., LTD (1433) |

|

Company Information

Market | TSE 1st Section |

Industry | Construction business |

President | Yoshihide Yoshino |

HQ Address | Kiba Park Bldg, 3-2-6 Hirano, Koto-ku, Tokyo, Japan |

Year-end | End of January |

Homepage |

Stock Information

Share Price | Share Outstanding (exc. Treasury Stock) | Market Cap. | ROE (Act.) | Trading Unit | |

¥932 | 8,226,770 shares | ¥7,667million | 2.3% | 100 shares | |

DPS (Est.) | Dividend Yield (Est.) | EPS (Est.) | PER (Est.) | BPS (Act.) | PBR (Act.) |

¥16.00 | 1.7% | ¥47.41 | 19.7x | ¥308.57 | 3.0x |

*The share price is the closing price on April 2. The number of shares issued was taken from the latest brief financial report excluding treasury stock. ROE and BPS are the values of the pervious term.

Consolidated Earnings

Fiscal Year | Net Sales | Operating Income | Ordinary Income | Net Income | EPS | DPS |

Jan. 2017 (Actual) | 4,182 | 397 | 404 | 271 | 32.85 | 40.00 |

Jan. 2018 (Actual) | 4,496 | 386 | 373 | 263 | 31.69 | 15.00 |

Jan. 2019 (Actual) | 4,927 | 497 | 495 | 621 | 75.25 | 15.00 |

Jan. 2020 (Actual) | 3,436 | 93 | 97 | 59 | 7.29 | 16.00 |

Jan. 2021 (Forecast) | 6,400 | 570 | 566 | 390 | 47.41 | 16.00 |

*Forecast is from the Company’s financial report. unit: million yen, yen

This Bridge Report reviews on the outlook of BESTERRA’s earnings results for the fiscal year ended January 2020 and its forecast of the fiscal year January ending 2021.

Table Contents

Key Points

1. Company Overview

2. Fiscal Year ended January 2020 Earnings Results

3. Fiscal Year ending January 2021 Earnings Forecasts

4. Medium-term Management Plan 2022 (FY 1/21 to FY 1/23)

5. Conclusions

<Reference: Activities for actualizing an advanced recycling society and measures for attaining SDGs>

<Reference: Regarding Corporate Governance>

Key Points

- For the term ended January 2020, sales and operating income dropped 30.3% and 81.3%, respectively, year on year. Sales decreased, because the orders for the projects which were expected to generate profit in the second half were delayed. Operating margin declined due to a decrease in sales and an increase in personnel cost as the number of employees grew, etc. REVER Holdings Corporation, with which the company has a capital and business alliance, got listed on the Second Section of the Tokyo Stock Exchange. The company also established 3D Visual KK, which offers 3D scan modeling and design services targeting plants. The annual dividend was 16 yen/share, up 1 yen/share from the previous term.

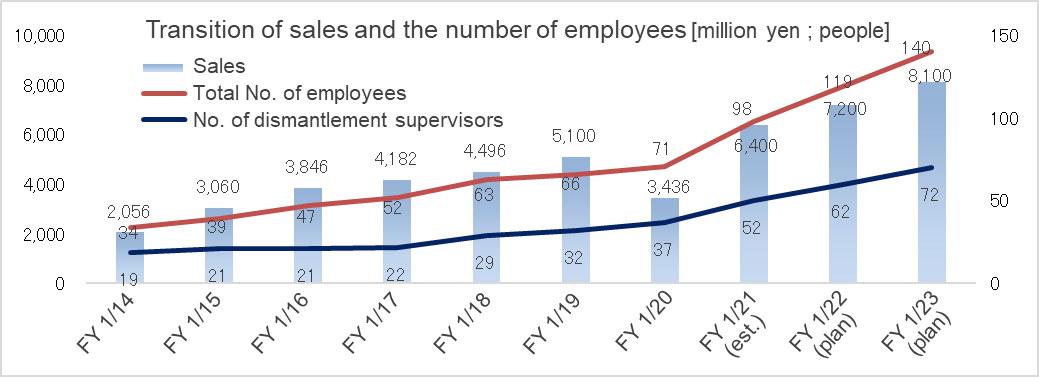

- For the FY ending January 2021, it is estimated that sales will increase 86.3% year on year, and operating income will grow 6.1 times year on year. With the V-shaped recovery, the company will get back on the track on the medium-term management plan. Sales are expected to increase due to the recovery in orders, and operating income is estimated to grow as the sales will absorb the augmentation of recruitment and personnel costs, etc. accompanying the increase in the number of employees by 27 (including 15 supervisors). The dividend will be 16 yen/share, including 6 yen/share at the end of the first half and 10 yen/share at the end of the year (expected payout rati 33.8%).

- Considering the business characteristic, the main business of the company is plant demolition, the business does not meet the condition such as being crowded with people, which is said could result in the coronavirus outbreak. Therefore, the coronavirus outbreak is less likely to affect the company. However, if there is an infected person within the company or on-site and the demolition schedule is delayed, the business performance will be negatively affected. For this reason, from the viewpoint of controlling the damage of the coronavirus outbreak inside and outside the company and ensuring the safety of employees and those involved in the business of the company, the company is implementing staggered working hours and telecommuting.

1. Company Overview

As a specialist in plant dismantlement, BESTERRA manages the dismantlement of plants (metal structures) for iron-making, power generation, gas, petroleum, etc. Its core competence is “the method and technology for dismantling plants,” and it has many patented methods including international patents. The company concentrates its managerial resources on engineering (proposal, design, and work planning) and management (supervision and work management), and outsources actual dismantlement work to its affiliates, and so it does not own heavy machinery or construction teams (the risk of owning assets can be avoided), and it is unnecessary to procure materials, etc. and make transactions for material production (the inventory risk can be avoided).

The Group also has two consolidated subsidiaries, Hiro Engineering, which provides human resource services for design work, etc. and 3D Visual KK, which handles 3D scan modeling and design work.

The corporate name “BESTERRA” was coined by combining the English word “Best (the superlative of ‘good’)” and the Latin word “Terra (the earth),” and、infused with the ambition to “create the best earth.” By developing an integrated system for dismantling and recycling, the company aims to actualize an advanced recycling society and contribute to the earth environment.

Corporate ethos and the code of conduct

Under the corporate ethos “We will contribute to the earth environment with our flexible way of thinking, creativity, and technologies using these concepts,” the company enacted the following code of conduct.

Long-term vision (Ideal state of the company)

・ Plant Demolition Leader in Japan

・ Proposing Plant Disassembly Technologies to the World

1-1 Characteristics of the business

The company has a single segment consisting of the plant demolition business. For others, it engages in the human resource service business and the 3D scan, modeling and design business.

| FY 1/19 | Ratio | FY 1/20 | Ratio | YoY |

Plant dismantlement business | 4,761 | 96.6% | 3,224 | 93.8% | -32.3% |

Others | 165 | 3.4% | 211 | 6.2% | +27.6% |

Consolidated sales | 4,927 | 100.0% | 3,436 | 100.0% | -30.3% |

Plant dismantlement business | 1,021 | 21.5% | 665 | 20.6% | -34.9% |

Others | 32 | 19.5% | 43 | 20.5% | +33.7% |

Adjustment amount | -556 | - | -615 | - | - |

Consolidated operating income | 497 | 10.1% | 93 | 2.7% | -81.3% |

*unit: million yen

Plant dismantlement business

In the plant dismantlement business, the company works on all types of plants in the fields of ironmaking, electric power, gas, petroleum and petrochemicals, etc. The company offers services on overall engineering processes including proposals, designing, work planning, outsourcing/arrangement of equipment and materials, supervision, safety management, cost management, financial management, and handling of governmental procedures. It focuses on designing its unique demolition technologies and supervising demolition works based on demolition plans, and uses specialized subcontractors for demolition works.

The clients for plant dismantlement are leading companies that own plants for ironmaking, electric power, gas, petroleum, etc. In most cases, the equipment installation companies of the corporate groups of clients or leading general contractors are entrusted with dismantlement, and then BESTERRA serves as the primary or second-tier subcontractor.

Also, in the plant dismantlement business, BESTERRA receives valuable materials generated through dismantlement, such as scrap, and sells them to scrap handlers. Accordingly, the company estimates the value of valuable materials while comprehensively considering material, quantity, price (market price of each material, such as iron, stainless steel, and copper), etc. and negotiates with clients about the fee for dismantlement work. In accounting, the gain from sale of valuable materials is included in revenue from dismantlement work, and posted as part of sales from completed dismantlement work. In some cases, contractors (clients) dispose of (sell) scrap, etc. by themselves.

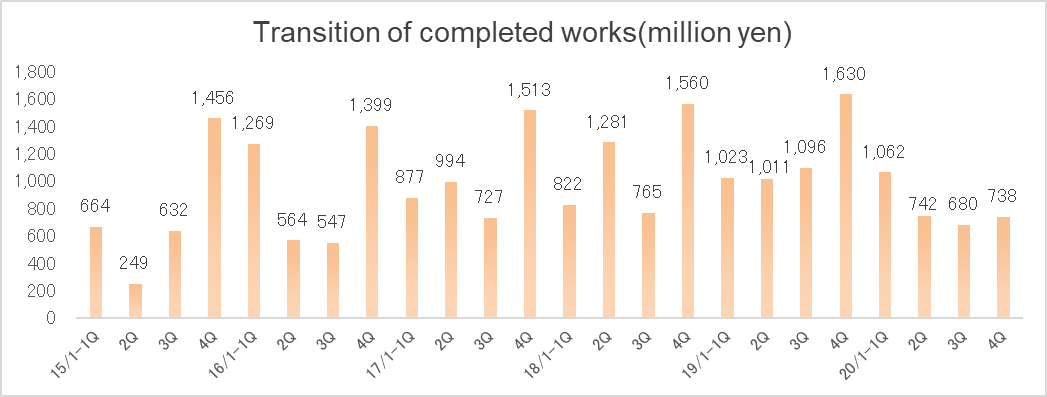

The number of completed works (rough estimates)

| FY 1/19 | Ratio to Sales | FY 1/20 | Ratio to sales | YoY |

Electric power | 1,666 | 35% | 419 | 13% | -75% |

Steelmaking | 1,952 | 41% | 1,837 | 57% | -6% |

Petroleum/petrochemical | 428 | 9% | 548 | 17% | +28% |

Gas | 666 | 14% | 290 | 9% | -56% |

Other | 47 | 1% | 128 | 4% | +172% |

Total | 4,761 | 100% | 3,224 | 100% | -32% |

*unit: million yen

*Two standards for posting revenue and seasonality of revenue posting of the company

The standards for posting revenue from contracts can be classified into the completed contract method, in which revenue is posted when works are completed, and the percentage-of-completion method, in which revenue is posted according to the progress of works. In the case of plant dismantlement, where valuables, such as scrap, are collected, revenue cannot be confirmed until the sale of scrap. Therefore, the company basically applies the percentage-of-completion method to large-scale projects whose contract amount exceeds 50 million yen and whose period exceeds 3 months, from the term ended January 2018 (the completed contract method is applied to the projects that are not applicable to the above criteria). The timing of posting revenue (the completion of demolition work) from works for which the completed contract method is used is often affected by the capital investment plans of clients. In the case of BESTERRA, revenue tends to be posted in the first quarter (February to April) and the fourth quarter (November to January) (the seasonality of revenue posting). However, the variation in quarterly performance may mislead investors, so the company is expanding the scope of application of the percentage-of-completion method step by step, to equalize the timings of revenue posting.

Others

In response to the chronic shortage of skilled construction workers, the company began providing human resource services in January 2013, and in March 2018, it made Hiro Engineering, which handles human resource services such as design work, a subsidiary. In January 2015, the company began offering a 3D measurement service as well. It established 3D Visual KK in December 2019, and 3D scan modeling and design business was transferred from INTER ACTION Corporation (securities code: 7725) in February 2020.

1-2 Strengths: an excellent client base, efficient dismantlement management based on plenty of experience, and intellectual property, such as patented methods

The strengths of the company are excellent client assets, efficient dismantlement management based on plenty of experience, and intellectual property, such as patented methods. Because the clients are basically engineering subsidiary companies of leading companies in ironmaking, electric, gas, coal oil fields, and major general contractors, which are easily trustable excellent clients, and it is predicted that they will receive orders continuously. The clients of the leading companies highly evaluate its company’s total management (low cost and high efficiency) of plant dismantlement that it cultivated experiences for over 40 years, and it elect a barrier to entry.

Furthermore, the company possesses a variety of technologies and know-how, which have been accumulated through environmental work, etc.

Patented methods, etc.

“Apple peeling demolition method” and fusing robot “Ringo☆Star”

The “apple peeling demolition method” is a method of dismantling a large spherical tank, such as gas holders and oil tanks, by cutting it in spirals from the center of the ceiling of the enclosure part. The cut part spirals down to the ground gradually under the force of the earth’s gravity (natural energy). The method enjoys superiority in a work period, cost, and safety, and has considerable competitive advantages, realizing “greater promptness, higher cost efficiency, and added safety.” Furthermore, the company offers a robot for the fusing process, “Ring☆Star,” which automates the “apple peeling demolition method.” (The company is also working to expand the range of applications for “Ringo☆Star” by developing a new attachment).

Environment-related methods

The company has cultivated experiences and business results of a multitude of environment-related demolition works, using the “fireless methods” which do not require the use of fire. For example, although polychlorinated biphenyls (PCBs) are considered as a toxic substance and therefore totally abolished today, it had been used for many years in transformers and condensers because of its excellent thermal stability and chemical stability (electric insulation characteristics). In many cases, transformers and condensers are disposed of in conjunction with plant demolition works; however, because PCBs gasify when they are treated at the high temperature, posing a risk of inhaling the gas so generated, any firearms (such as gas cutting machines) cannot be used in demolition and withdrawal involving PCBs. The company is skillful at fireless and quasi-fireless methods using saber saws (which cut off objects with their saw blades moving in a reciprocating manner) that can cut off objects thicker than the thickness, which, in the industry, had been considered impossible to cut, through numerous devices, including measures against seizure of motors and recycling of blades. BESTERRA has applied for joint patents with Hitachi Plant Construction, Ltd. for a transformer dismantling method, a transformer dismantling jig, and a cutting device for dismantling a transformer.

Windmill demolition works

The number of power-generating wind turbines continues to increase by about 20% annually worldwide, but the demand for dismantling is expected to increase in the future due to wear and tear and economic obsolescence. According to the material presented by the company, the wind power generation volume worldwide is 486,790 MW (by about 340,000 onshore power generation plants and about 4,000 offshore ones) with an annual growth rate of about 20%. In Japan, the number of wind power generation plants stood at 2,225 as of the end of 2017, expanding by about 90 every year. Meanwhile, as the useful life is approximately 15 to 20 years, and the windmills for power generation established in the early stage are reaching the application limit. Moreover, not a few plants need to be dismantled due to damage or fatal failure caused by thunderbolts or typhoons.

How to knock down a power-generating wind turbine (international patent application)

As some windmills have been built in mountain districts and on the sea, demolition of them is highly difficult. The company has devised a method for dismantling wind turbines that does not require scaffolds, and has already acquired a domestic patent for “Method of knocking down a power-generating wind turbine.” International patents are pending for “Method of knocking down towering structures using their bases” and “Method for dismantling tower-shaped equipment for wind power generation.” Safety of workers can be improved dramatically and the work period can be shortened by using these patent-based methods.

Pursuit of the value of the 3D business

Using services such as layout simulation, strain/bending/torsion measurement, comparison of structures before and after improvement, and video walkthroughs, the company converts physical data taken when plants were established (more than 30 years ago) into the latest 3D data, and uses that to provide detailed information about the dismantling process. They also provide unique 3D measurement services for dismantling work using the latest measuring technology and simulation systems that are capable of drawing data as 2D diagrams, handling BIM/CIM modeling, Perfect 3D, and 3D printing, etc.

“Visualize” the dismantling process

Layout simulation | The equipment models produced with 3D CAD are placed in 3D data, and the replacement of equipment can be simulated. By moving the equipment models, it is possible to check how they interfere and collide with one another. |

Strain, bending, and torsion measurements | It is possible to measure changes in shapes. This is useful for diagnosing frameworks tentatively, to check whether a building got distorted due to an earthquake, deterioration, etc. |

Comparison of structures before and after installation

| The shapes of equipment that changes due to heat and vibration, such as pipes, conveyors, and furnaces, at the time of installation and after operation are compared. With 3D data, it is possible to grasp overall changes intuitively. |

Video walkthroughs

| Walk-through videos are produced by using synthesized point cloud data. These videos can be utilized for presentations and publicity videos regarding dismantlement plans and real estate information. |

Unique 3D measurement service

Draws a two-dimensional diagram | The 3D CAD models based on point cloud data are converted into drawings. It is also possible to produce drawings directly from point cloud data in a simple manner. |

Handles BIM/CIM modeling | Modeling is conducted with 3D CAD based on point cloud data. It is possible to produce models of the parts that require construction or renovation as BIM (building information modeling) data. |

Perfect 3D | This is a large-scale 3D data measurement service combining automobile-based MMS (mobile mapping system), airborne laser measurement, water area measurement, etc. |

3D printing | After modeling with point cloud data, data are processed and deformed so that they can be shaped with a 3D printer. It can produce fine structures with a lamination pitch of 15 μm. |

2. Fiscal Year ended January 2020 Earnings Results

2-1 Consolidated results

| FY 1/19 | Ratio to sales | FY 1/20 | Ratio to sales | YoY | Forecast revised at the 3Q | Compared to forecast |

Sales | 4,927 | 100.0% | 3,436 | 100.0% | -30.3% | 3,540 | -2.9% |

Gross profit | 1,054 | 21.4% | 708 | 20.6% | -32.8% | - | - |

SG&A expenses | 556 | 11.3% | 615 | 17.9% | +10.7% | - | - |

Operating income | 497 | 10.1% | 93 | 2.7% | -81.3% | 120 | -22.3% |

Ordinary income | 495 | 10.1% | 97 | 2.8% | -80.4% | 120 | -19.0% |

Profit attributable to owners of the parent | 621 | 12.6% | 59 | 1.7% | -90.4% | 74 | -23.4% |

*unit: million yen

Sales and operating income decreased 30.3% and 81.3% year on year, respectively

Sales declined 30.3% year on year to 3,436 million yen. As the orders for the projects which were scheduled to generate profit in the second half were delayed, sales decreased. Operating income decreased 81.3% year on year to 93 million yen. Gross profit margin declined 0.8 points to 20.6% (22.8% in the first half) due to a fall in the operation rate in the second half, while SG&A expenses increased, mainly in recruitment, personnel and R&D expenses.

Orders received decreased 8.8% year on year to 3,249 million yen. The backlog of orders at the end of the term was 1,046 million yen, up 2.5% from the end of the previous year.

Since the decreases in sales and profit are temporary, the company plans to pay a year-end dividend of 16 yen/share, up 1 yen/share, as announced at the beginning of the fiscal year (payout rati 219.5%).

The number of completed works by sector (rough estimates)

| FY 1/19 | Ratio to sales | FY 1/20 | Ratio to sales | Increase /Decrease |

Electric power | 1,666 | 35% | 419 | 13% | -75% |

Steelmaking | 1,952 | 41% | 1,837 | 57% | -6% |

Petroleum/petrochemical | 428 | 9% | 548 | 17% | +28% |

Gas | 666 | 14% | 290 | 9% | -56% |

Other | 47 | 1% | 128 | 4% | +172% |

Total | 4,761 | 100% | 3,224 | 100% | -32% |

*unit: million yen

The amount of completion work was recorded mainly in the ironmaking industry, where demand for demolition in western Japan is strong.

Breakdown of SG&A and major change factors

| FY 1/19 | Ratio to sales | FY 1/20 | Ratio to sales | Increase /Decrease | Major change factors |

Salaries and allowances | 280 | 5.7% | 327 | 9.5% | +16.7% | Increase in head office staff |

R&D cost | 9 | 0.2% | 16 | 0.5% | +71.3% | Development of Robots |

Commissions and remunerations paid | 52 | 1.1% | 53 | 1.5% | +1.0% | The upgrade of basic system |

Recruitment cost | 12 | 0.2% | 16 | 0.5% | +37.0% | Advertising media, referral fee |

Advertisement | 17 | 0.3% | 10 | 0.3% | -42.9% | Decrease of exhibition |

Other | 182 | 3.7% | 190 | 5.5% | +4.3% | Leasing expense of head office building |

Total SG&A expenses | 556 | 11.3% | 615 | 17.9% | +10.7% |

|

*unit: million yen

Salaries and allowances increased due to base upgrades and an increase in the number of employees, mainly supervisors, etc. R&D cost increased because of the development of a robot for inspecting crane rails. The number of supervisors at the end of the fiscal year was 37, up 5 from the same period last year.

Orders received and the backlog of orders

| FY 1/19 | FY 1/20 | YoY |

The backlog of orders at the beginning of the term | 2,218 | 1,021 | -53.9% |

The amount of works received | 3,565 | 3,249 | -8.8% |

The amount of completed works | 4,761 | 3,224 | -32.3% |

The backlog of orders at the end of the term | 1,021 | 1,046 | +2.5% |

*unit: million yen

The backlog of orders by sector (Amounts are approximate.)

| FY 1/19 | Ratio | FY 1/20 | Ratio | Increase /Decrease |

Electric power | 275 | 27% | 73 | 7% | -73% |

Steelmaking | 429 | 42% | 565 | 54% | +32% |

Petroleum/petrochemical | 224 | 22% | 397 | 38% | +77% |

Gas | 51 | 5% | - | - | - |

Other | 40 | 4% | 10 | 1% | -75% |

Total | 1,021 | 100% | 1,046 | 100% | +2% |

*unit: million yen

The backlog of orders grew in the ironmaking industry, which is undergoing a large-scale renewal in western Japan, and the petroleum and petrochemical industries (successful in identifying major chemical manufacturers), which are strengthening sales operations. The orders from the electric power industry declined due to a lull in large-scale projects and the issues of human resources, etc.

2-2 Financial condition and cash flow(CF)

Financial condition

| Jan. 19 | Jan. 20 |

| Jan. 19 | Jan.20 |

Cash | 2,032 | 938 | Payables | 1,357 | 347 |

Notes receivable, accounts receivable from completed construction contracts and other | 1,785 | 708 | Taxes Payable | 250 | 0 |

Current Assets | 4,059 | 1,965 | Borrowings and Bonds | 10 | 1,756 |

Tangible Assets | 265 | 267 | Liabilities | 1,949 | 2,400 |

Investments, Others | 212 | 2,680 | Net Assets | 2,614 | 2,540 |

Noncurrent Assets | 504 | 2,975 | Total Liabilities, Net Assets | 4,564 | 4,941 |

*unit: million yen

The total assets as of the end of the fiscal year stood at 4,941 million yen, up 376 million yen from the end of the previous term. As for debits, cash and deposits decreased due to share acquisition (14.59% of issued shares) based on a capital and business alliance with REVER Holdings Corporation, while investment securities increased. On the credit side, long-term borrowings increased in line with the above acquisition of shares and an increase in operating capital. Equity ratio was 51.4% (57.2% at the end of the previous fiscal year).

REVER Holdings Corporation got listed on the Second Section of the Tokyo Stock Exchange on March 24, 2020 (securities code: 5690).

Outline of REVER Holdings Corporation

REVER Holdings Corporation is a holding company that operates the businesses of recycling metal, home appliances, and automobiles, disposing of industrial waste, etc. via 10 subsidiaries. Its corporate group has 20 odd footholds mainly in the Kanto region, and in Shizuoka and Osaka. It has a history of over 110 years. REVER Holdings is a leading material recycler in Japan, and has been pursuing the economies of scale through active M&A in the field filled with small and medium-sized enterprises, with the aim of becoming a Japanese giant material recycling company.

The Japanese venous industry(material recycle) has been fragmented and filled with small and medium-sized enterprises, and their thought of “the shift to the scale business would improve the advantage of the industry itself and contribute to the actualization of an advanced recycling society” led to a capital and business alliance with BESTERRA. Through the capital and business tie-ups, the company will create an environmental supply chain (a platform in the venous industry), and call on small-sized enterprises to join the platform, with the aim of becoming a major company in the Japanese venous industry.

Cash Flow(CF)

| FY 1/19 | FY 1/20 | YoY | |

Operating Cash Flow | 1,753 | -153 | -1,907 | - |

Investing Cash Flow | 298 | -2,543 | -2,841 | - |

Financing Cash Flow | -777 | 1,604 | +2,381 | - |

Cash and Equivalents at Term End | 2,031 | 938 | -1,092 | -53.8% |

*unit: million yen

Reference: Trend of ROE and ROA

| FY 1/16 | FY 1/17 | FY 1/18 | FY 1/19 | FY 1/20 |

ROE | 18.43% | 12.81% | 11.69% | 23.81% | 2.33% |

ROA | 10.26% | 7.28% | 6.49% | 13.6% | 1.26% |

Net income margin | 7.60% | 6.48% | 5.87% | 12.62% | 1.75% |

Total asset turnover [times] | 1.35 | 1.12 | 1.11 | 1.08 | 0.72 |

Leverage [times] | 1.80 | 1.76 | 1.80 | 1.75 | 1.84 |

*ROE = Net income margin x Total asset turnover x Leverage

*Total asset and Equity are the average balance in the term

3. Fiscal Year ending January 2021 Earnings Forecasts

3-1 Consolidated Earnings

| FY 1/20 | Ratio to sales | FY 1/21(forecast) | Ratio to sales | YoY |

Sales | 3,436 | 100.0% | 6,400 | 100.0% | +86.3% |

Operating income | 93 | 2.7% | 570 | 8.9% | +511.6% |

Ordinary income | 97 | 2.8% | 566 | 8.8% | +482.2% |

Profit attributable to owners of the parent | 59 | 1.7% | 390 | 6.1% | +550.4% |

*unit: million yen

It is estimated that sales and operating income will grow 86.3% and 6.1 times, respectively, year on year

With the V-shaped recovery, the company will get back on the track on the medium-term management plan. It will make efforts in acquiring projects by strengthening sales of proposals based on the strategy to patent technologies. It will also implement a personnel strategy centered on strengthening recruitment and development and improving the workplace environment. In addition, it will flexibly work on M&A to secure excellent human resources and develop innovative new services, while pursuing group synergies by strengthening cooperation with the consolidated subsidiaries.

It is estimated that sales will increase 86.3% year on year to 6.4 billion yen due to a recovery in orders. Sales will absorb increases of recruitment and personnel costs accompanying the increase in the number of employees by 27 (including 15 supervisors). Consequently, operating income is estimated to increase 6.1 times year on year to 570 million yen.

The annual dividend will be 16 yen/share, including 6 yen/share at the end of the first half and 10 yen/share at the end of the year (expected payout rati 33.8%).

3-2 The company reorganized 3D Visual KK into a subsidiary

On February 1, 2020, a wholly owned subsidiary, 3D Visual KK, acquired a business of 3D scanning, modeling, and design services for plants from INTER ACTION Corporation (securities code: 7725). INTER ACTION Corporation decided to transfer the business, despite strong performance of the business, mainly in the design service, because it was difficult to expect synergy with its main business.

The company will pursue synergies, including mutual referral of customers, by developing businesses from different perspectives with BESTERRA as a demolition company and 3D Visual KK as a design company. In the medium term, they are intending to use the technology to enhance dismantling work.

3D Visual KK was established in December 2019 for 3D scanning and modeling, design and analysis, equipment inspection, dispatch of designers, and software training.

3-3 Impact of the coronavirus outbreak

Considering the business characteristic, the main business of the company is plant demolition, the business does not meet the condition such as being crowded with people, which is said could result in the coronavirus outbreak. Therefore, the coronavirus outbreak is less likely to affect the company. It was not affected by the outbreak in the term ended January 2020, because its financial settlement was January.

The company expects that the situation will remain unchanged in the term ending January 2021. However, if there is an infected person in the company or on-site and the demolition schedule is delayed, the impact of the outbreak on business performance is inevitable. For this reason, from the viewpoint of controlling the damage of the coronavirus outbreak inside and outside the company and ensuring the safety of employees and those involved in the business of the company, the company is implementing staggered working hours and telecommuting. Furthermore, alcohol for disinfection is placed on each floor of the company, and cleaning solutions for gargling are distributed to employees. The employees are also recommended to take individual infection prevention measures.

4. Medium-Term Management Plan 2022 (FY 1/21 to FY 1/23)

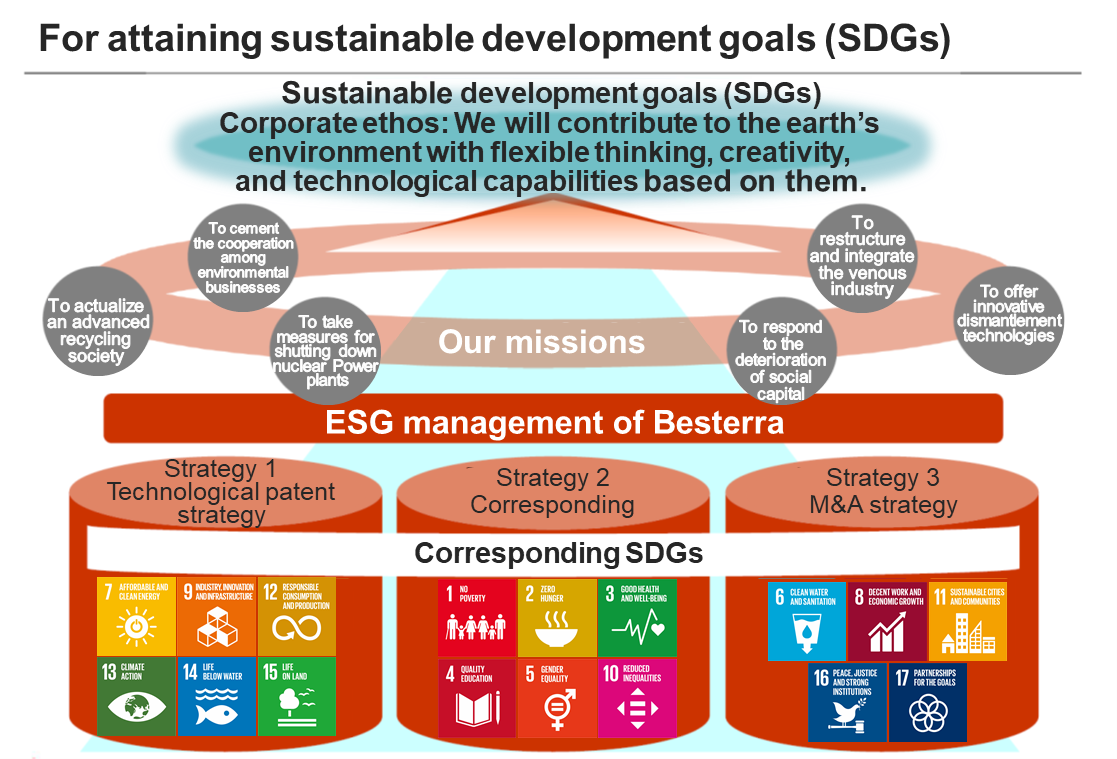

4-1 SDGs/ESG and the company

It will carry out ESG management mainly by working on safety (creating a safe culture with its original technologies), R&D (developing innovative construction methods friendly to the earth), recycling (building an advanced environmental cycle by strengthening the venous industry), governance (thorough transparency and risk control), and human resources (pursuit of worthwhile jobs and growth of individuals). Furthermore, as a leader of the plant dismantlement industry, it will be making efforts to realize a highly recycling-oriented society, taking nuclear power plant decommissioning measures, and working on responses to aging social capital. It will also facilitate the reorganization and integration of the venous industry by sharing and promoting the management policy with REVER Holdings Corporation that aims to be a major company in the venous industry. Through ESG management and these activities, it intends to contribute to the achievement of the Sustainable Development Goals (SDGs) while aiming for the best earth (BEST TERRA), as the company’s name represents.

(Source: Company’s material)

4-2 Three Strategies

Under the belief that “nothing is unbreakable by BESTERRA, a pioneer in dismantling plants,” the company will continue to develop businesses that mainly target plants that require the most technical skills in demolition work. Specifically, it will promote three strategies: the technology patent strategy, human resources strategy, and M&A strategy.

Strategy 1: Technology patent strategy

It will identify potential demand by providing innovative dismantling technologies such as 3D dismantling, patented methods (apple peeling demolition method, robot method, environment-related methods, windmill dismantling method), 3D business, and a robot for inspecting crane rails. At the same time, it will contribute to the global environment by improving safety, recycling, and productivity.

3D dismantling

Combining the latest measurement technology with the know-how of dismantling work, the company offers a unique “3D dismantling” service. The “3D dismantling” is implemented based on modeling data (drawing data) created from point cloud data in a short period of time using “3D measurement (point cloud data conversion)” to convert the current situation of a complex plant without blueprints. This is an advanced dismantling method that is different from the conventional ones that are based on experiences and intuition. The company continuously accumulates and shares new dismantling methods and know-how obtained from the workplace, leading to new technology development and patent acquisition.

Patented methods

The company owns many competitive patented methods. It intends to increase orders by proposing dismantling methods using these patented methods.

Major patented methods

Apple peeling demolition method | It is a method with excellent demolition period, cost, safety and is highly competitive. When dismantling a spherical storage tank such as a gas holder or oil tank, a spiral cut is made from the center of the outer ceiling like peeling an apple. |

Robot method | The company is evolving the “Ringo☆Star” used in the apple peeling demolition method. It is also working on a new robot development. “Ringo☆Star” can be used in a wider range by developing new attachments. |

Environment-related methods | The company has abundant demolition experience with the “fireless methods” that does not use fire. The “fireless methods” is suitable for disassembling and disposing of transformers containing harmful substances (i.e. PCB) that cannot be used firearms on (gas fusing, etc.) in demolition and withdrawal. It is based on the technology that cuts large equipment with a thickness that exceeds common sense in the industry by using saber saws (which cut off objects with their saw blades moving in a reciprocating manner) etc. and other unique know-how. The “fireless methods” also works well for the places where there are asbestos and dioxin. |

Windmill dismantling method | The number of wind turbines for power generation is growing at a rate of about 20% annually worldwide. Demand for dismantlement is estimated to increase due to their expiration and economic obsolescence in the future. |

3D Business

The lineup of measurement services will be expanded by adding modeling (drawing), 3D layout simulation, distortion/bending/twist measurement, Before/After shape comparison, walk-through video, 2D drawing, BIM/CIM modeling, perfect 3D, and 3D printing on 3D measurement.

A robot for inspecting crane rails

The company and iXs Co., Ltd. jointly developed an autonomous robot that runs on crane rails and performs efficient periodic inspection of overhead cranes that are installed in plants and factories for transporting heavy objects and parts, etc. Overhead cranes can be distorted due to aging, etc., and if left as it is, a serious accident may occur. For this reason, the Industrial Safety and Health Act’s safety regulations for cranes, etc. stipulates that companies that use overhead cranes must perform voluntary inspections once a year and once a month. The domestic market size of overhead crane inspection is estimated to be more than 30 billion yen per year (estimated by the company). There are wide demand bases, such as general contractors, logistics, and maintenance companies, and the company is eager to develop new customers.

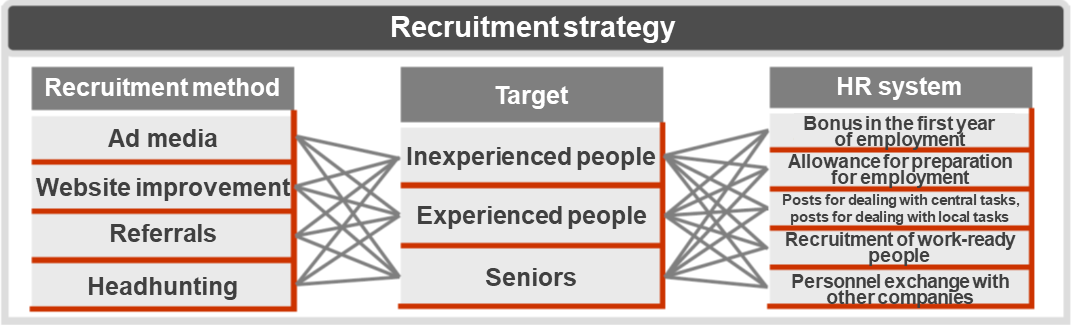

Strategy 2: Human Resource Strategy

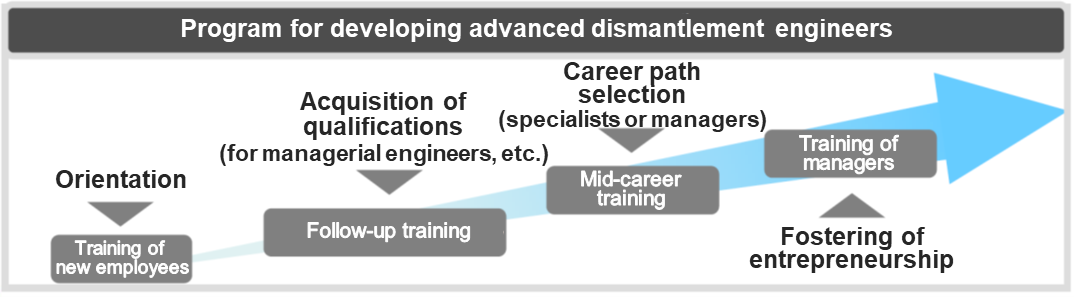

The company specializes in demolition management for demolition work, and it needs to place supervisors at every site. Therefore, increasing the number of supervisors is essential for sustainable growth. In order to increase the number of supervisors and improve their ability in a short period of time, the company will implement an efficient recruiting strategy and work on establishing a training program. It will also focus on creating mechanisms that allow the employees to work with peace of mind.

(Source: Company’s material)

An efficient recruitment strategy aims to achieve a personnel plan by clarifying recruitment methods and targets and establishing a personnel system that has a direct effect on recruitment. At the time of recruiting, the targets are divided into inexperienced people, experienced people, and seniors, and effective recruiting methods such as advertising media, putting on the web-sites, referrals, headhunting, etc. are used.

(Source: Company’s material)

For establishing a training program, the company will implement a “training program” to transfer technology from experienced engineers to inexperienced ones. Furthermore, the “Demolition Professional Course” and “Management Course” will be established as an evaluation system in line with the actual situation of supervisors. The “Qualification Promotion System” will also be expanded to support skill improvement. Furthermore, a personnel system that places emphasis on individual work styles will be formulated.

As for the development of a worker-friendly mechanism, in the construction industry, where working on Saturdays is common, the company introduced a five-day workweek system for all employees ahead of its rivals. In the future, it will introduce “shift (time) management by executives,” “workplace (labor) rotation” and “health management” and other various systems as measures to create a worker-friendly environment, where employees can work with a peace of mind for a long time.

Income insurance that has the highest level in Japan (Income compensation insurance) | Insurance for which the premium is fully covered by the company to compensate for the loss of income when an employee cannot work for a long time due to injury or illness. 50% of monthly remuneration will be reimbursed until retirement (age 60). |

Retirement plan | A retirement allowance system is in place so that employees can work for a long time until retirement and enjoy a fulfilling life after retirement. |

A generous grant to the employee shareholding association | An employee shareholding association is established where employees hold their own shares by a funding method. Incentives earned by members are subsidized by a 15% rebate purchase of treasury stock to encourage employees to build their assets. |

Special paid leave (preserved annual paid leave) | The typical maximum number of days of paid leave is 40 days under the Labor Standards Act, but the company allows the employees to hold up to 80 days of paid leave in case of medical treatment due to injury or illness. |

Strategy 3: M&A Strategies

The company will implement M&A flexibly to secure excellent human resources and develop innovative new services. In addition, it will pursue group synergy by strengthening cooperation with Hiro Engineering, through which the M&A effects are not fully demonstrated yet, and 3D Visual KK which acquired the 3D scan modeling business from INTER ACTION Corporation (securities code: 7725).

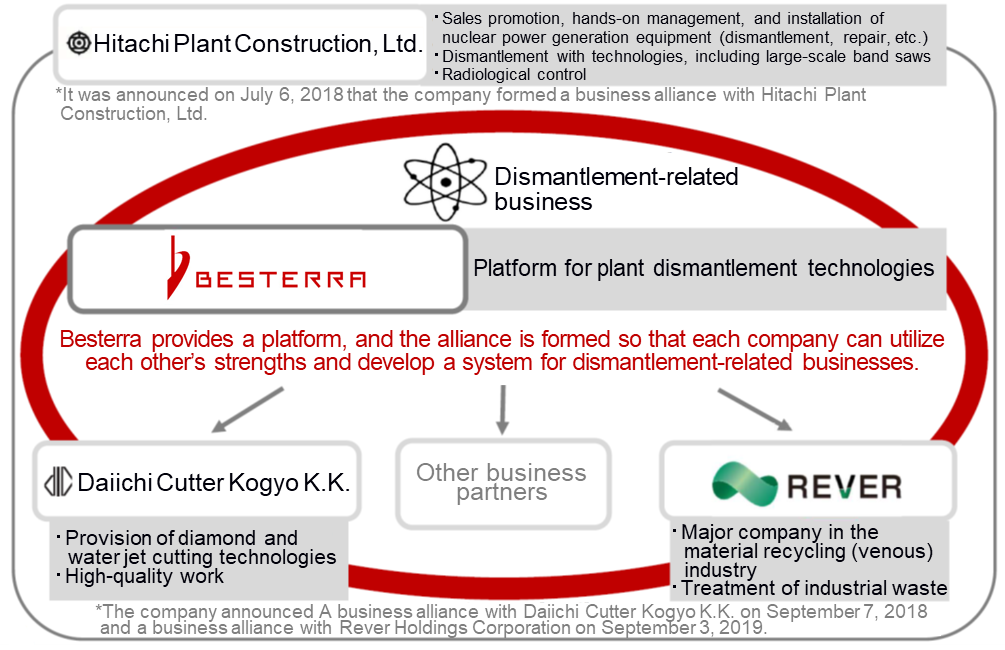

Response to decommissioning of nuclear power facilities

There are 60 reactors at 19 locations in Japan, and the decommissioning of 24 units has already been decided. It is estimated that the decommissioning business will accelerate and expand from now on as the examination of conformity with the new regulatory standards progresses. The company is contributing to the efforts to decommission nuclear power generation plants, which is a national issue, by providing technologies and know-how cultivated in plant demolition work. As part of this effort, in July 2018, the company established a business alliance with Hitachi Plant Construction, Ltd., which has the know-how and technology of sales, on-site management, and demolition of nuclear power generation plants (decommissioning, renovation, etc.) and handles dismantling work and radiation management using demolition techniques using large band saws, etc.

In addition, the company itself is working as a platform to expand tie-ups with specialized contractors, etc., and is working on building a “decommission-related business platform” that leverages the strengths of each company in the work related to decommissioning nuclear power plants. For this purpose, it is facilitating collaboration and M&A. In September 2018, the company concluded a business alliance agreement with Daiichi Cutter Kogyo K.K., Japan’s leading company for the diamond method and water jet method that are required for the maintenance and repair of structures. In September 2019, the Group concluded a capital and business alliance agreement with REVER Holdings Corporation, which operates a recycling business and an industrial waste treatment business, etc.

(Source: Company’s material)

Creation of an environmental supply chain

The company will also work with REVER Holdings Corporation to create an environmental supply chain. While BESTERRA Co., Ltd. mainly operates the dismantlement business, which is positioned between the arterial industry (including electric power, steelmaking, and petrochemistry) and the venous industry (including scrap and industrial waste), REVER Holdings Corporation mainly conducts the intermediate processing of scrap, industrial waste, etc. in the venous industry. While the market is expected to expand in response to the deterioration of social infrastructure, etc. the two companies are intending to play a role in coordinating the “arterial industry” and the “venous industry” establish an indispensable position in the advanced recycling society by joining hands in the medium to long term.

Other strategies

The company will work on improving profitability and increasing sales bases by expanding direct orders.

To increase the number of direct orders, it will enhance its name recognition by increasing advertising media such as exhibitions, web-sites, promotional materials, etc. Furthermore, since the company can propose a plan based on the demolition plan of the client, it has knowledge about the demolition system of the primary contractor. It will also strengthen the structure by establishing a qualification acquisition system, increasing the number of sales assistants, and carrying out the personnel structure reform.

In order to expand sales bases, the company is planning to establish new bases in industrial areas in Kyushu or Sendai, etc. so that they can accept more recurring-revenue orders (projects that receive continuous orders from customer groups, being stationed at factories, the apple peeling demolition method, PCB processing work, etc.).

4-3 Numerical targets

| FY ending January 2021 | FY ending January 2022 | FY ending January 2023 |

Sales | 6,400 | 7,200 | 8,100 |

Operating income | 570 | 650 | 740 |

Ordinary income | 566 | 645 | 735 |

Net income attributable to owners of the parent | 390 | 455 | 523 |

Operating margin | 8.9% | 9.0% | 9.1% |

EPS | 47 yen | 55 yen | 63 yen |

*Unit: Million yen

Although the business performance was down in the term ended January 2020 due to a temporary factor, a V-shaped recovery is expected in the term ending January 2021 as the orders are recovering. Despite the large fluctuations in business performance in the term ended January 2020 and the term ending January 2021, basically, both sales and profits are targeted for continuous growth of more than 10% from the previous year. It is targeting sales of 8,100 million yen and an operating income of 740 million yen in the final year (the term ending January 2023).

4-4 Profit distribution/shareholder return policy

While considering “investment for future growth” and “internal reserves for strengthening the business base,” the company is intending to pay dividends with a payout ratio of 40%. In addition to dividends, a QUO card of 1,000 yen is offered to shareholders holding one unit (100 shares) or more and 2,000 yen to shareholders holding three units (300 shares) or more as shareholder benefits.

“Investment for future growth” means human resource investment (recruitment/training costs), technology development investment (demolition method/robot development), system investment (3D system, BIM/CIM), and strategic business investment (M&A cost). It will allocate the funds reasonably.

4-5 New executive structure

At the Ordinary General Meeting of Shareholders scheduled to be held on April 23, 2020, and at the Board of Directors meeting that will be held after that, Mr. Yoshihide Yoshino, current President and CEO will be the Representative Director and Chairman, and Mr. Akitatsu Yoshino, current Senior Managing Director and Executive Director of Operations will be the President and CEO. To respond to the changes in the business environment, the company will transform the structure from one representative director to two, and strengthen top management to further strengthen corporate governance and management. This way, it aims at enhancing the corporate value and generating further growth.

Senior Managing Director Yoshino has been active as the right arm of President Yoshino, mainly in the sales field, since the company was still small. On the other hand, President Yoshino is an engineer rather than a merchant, and is good at patents, etc. Therefore, from now on, the new president will oversee BESTERRA’s business strategy, and the former president Yoshino will, as chairperson, be in charge of technologies and efforts with REVER Holdings Corporation for becoming a major company in the venous industry.

Message to shareholders and investors from Mr. Yoshino, the next president

|

The other day, we announced the three-year plan together with the financial results. We always set high goals, but we are aiming to achieve this three-year plan, first. I am just an ordinary person compared to the current president. Therefore, I cannot talk about large-scale dreams like the current president, but as one of the employees who has been managing the work of BESTERRA from the very beginning, I would like to take some weight off from the current president’s shoulders and be in charge of the growing fields of the company.

I also would like to achieve our long-term vision, “To be the leader of the plant dismantling industry in Japan” as early as possible. The next goal is to become a “proposer of plant dismantling technology to the world.” I would like to ask for your continued support. |

5. Conclusions

In 2019, partially due to preparation for the Olympics, shortage of manpower and high construction materials became prominent, and the general contractors temporarily refrained from receiving and ordering. Consequently, orders in the dismantlement industry mostly from general contractors also fell. Due to this issue, orders of two large-scale projects, which were scheduled to take place in the term ending January 2021, were delayed. Also, the company refrained from taking unreasonable orders to cover the delay, because personnel costs rose sharply.

On the other hand, the company focused on obtaining direct (primary contract) orders. Considering the current situation where orders are received mainly through general contractors, general contractors should not be ignored. Nonetheless, business opportunities through direct orders are increasing as the clients become more cost-conscious. Subsequently, the company has been successfully establishing business relationships with several major chemical manufacturers. The key industries for the company’s business are electric power, ironmaking, petroleum and petrochemicals. However, the electric power industry has a strong connection with traditional trading companies, and the ironmaking industry basically requires an engineering subsidiary to operate business. Meanwhile, the petroleum and petrochemical industries do not have such “constrains.” The company carried out sales activities in these industries while gaining the consensus of general contractors. Consequently, the ratio of direct orders received, which was about 10% in the term ended January 2020, is likely to exceed 20% in the term ending January 2021.

In the term ending January 2021, when V-shaped recovery is expected, despite uncertainties caused by the coronavirus outbreak, the direct order projects in the petroleum and petrochemical industries are expected to increase. Furthermore, in the ironmaking industry, a large scale of dismantlement projects in association with renewal of facilities for a major manufacturer will be available. The company also secured employment of 5 new supervisors by the end of the first quarter and is planning to hire 10 more later (a total of 5 people in the term ended January 2020). The total number of supervisors, including the newly joined 5, is 42, which is enough to achieve the sales of 6,400 million yen in the term ending January 2021. For this reason, future hiring activities will be in anticipation of the next term onward.

In the medium term, prospects for demolition work are bright, because the facilities constructed during the period of high economic growth are expected to reach the time of dismantlement/renewal due to physical obsolescence and economic obsolescence, etc. We would like to pay attention to the actualization of group synergies, responses to nuclear power generation facilities, and major venous measures.

<Reference: Activities for actualizing an advanced recycling society and measures for attaining SDGs>

Roles and activities of the company for actualizing an advanced recycling society

At a global level, the company aims to actualize BEST (the best) TERRA (the earth), which is the corporate name, by contributing to the earth environment by making efforts to attain Sustainable Development Goals (SDGs). In Japan, the company will work on the response to the measures for abandoning nuclear power plants and measures for coping with the deterioration of infrastructure, in addition to the actualization of an advanced recycling society. Then, as a leader in the plant dismantlement field, the company will lead the restructuring and integration of the venous industry by shifting to the scale business (connecting the arterial and venous sectors), and offer innovative demolition technologies. For the cooperation with the venous sector, the company will actualize and strengthen an integrated environment-related business by combining the demolition/wrecking business, the recycling business, and the industrial waste disposal business.

BESTERRA’s response to SDGs

The company will develop a workplace environment where worthwhile jobs are offered

(Source: Company’s material)

The company has been pursuing a workplace environment where worthwhile jobs are offered, and it is developing a personnel evaluation system, taking measures for the employee shareholding association, and establishing systems for incentives, income insurance, etc. so that employees can work with peace of mind. In the cumulative second quarter of the term ended January 2020, the company raised basic pay and enriched a qualification allowance, etc. |

The company will provide innovative demolition technologies and contribute to the global environment

(Source: Company’s material)

The provision of innovative technologies is the company’s core business and strength. In addition to various patented methods, the company has adopted 3D technologies for dealing with large-scale projects. |

The company will achieve an advanced recycling society and contribute to building a sustainable society

(Source: Company’s material)

The company has been performing environmentally friendly works, but will improve them further and offer one-stop services. Many of the company’s client companies operate business in the key industries, and the clients themselves are required to take environmental measures. The company plans to meet the clients’ requests. |

Partnership for building a sustainable (an advanced recycling) society

(Source: Company’s material)

Overcoming barriers, the company will focus on the fostering of partnership for achieving higher goals. In order to realize an advanced recycling society, the company will offer new technologies, knowledge, and insights with the aim of achieving goals. To do so, the company will cooperate with various companies. |

Contribution to social sustainability and growth of profit through ESG management

The company will conduct ESG management by working on safety (creating a safe culture with its original technologies), R&D (developing innovative methods friendly to the earth), recycling (actualizing advanced environmental cycling by strengthening the venous industry), governance (thoroughgoing transparency and risk control), and human resources (pursuit of worthwhile jobs and growth of individuals), and contribute to social sustainability while growing profit. As the understanding of these activities is deepened, ESG investment will be made in the plant dismantlement and recycling industries.

<Reference: Regarding Corporate Governance>

◎ Organization type and the composition of directors and auditors

Organization type | Company with auditors |

Directors | 9 directors, including 2 outside ones |

Auditors | 3 auditors, including 3 outside ones |

◎ Corporate Governance Report Update date: April 26, 2019

Basic policy

In order to promote sound business administration and win social trust sufficiently, our company recognizes corporate governance as the most important issue, puts importance on the improvement of the soundness, transparency, and fairness of business administration, and complies with laws and regulations thoroughly, and all executives operate business while keeping in mind that “the violation of laws or regulations would lead to management responsibility.” In detail, our company disseminates and executes business pursuant to laws, regulations, and in-company rules thoroughly, by developing appropriate systems for making decisions about business administration, fulfilling duties, supervising work, conducting internal control, etc.

It is also important to reform management systems for “achieving appropriate share price” and “increasing share price sustainably” to emphasize shareholders and strengthen the function to check business administration, to establish global-level corporate governance. The results of such efforts would win the trust of society, increase corporate value, and satisfy shareholders.

<Reasons for Non-compliance with the Principles of the Corporate Governance Code (Excerpts)>

【Supplementary principle 4-1-3】

There is no concrete plan regarding the succession of the CEO (chief executive officer). As a policy for the selection of a successor in the Board of Directors meeting, we will select a suitable candidate by taking his/her character, insight and achievements into account. The Board of Directors will actively take part in activities of making and carrying out a succession plan.

【Supplementary principle 4-3-3】

Our company has not established a clear procedure ensuring objectivity, timeliness and transparency for dismissal of the president or CEO, but we strive to realize a mutual assessment by involving outside directors in the process of evaluation of nomination and remuneration of the Board of Directors, in order to carry out the assessment of effectiveness of the Board of Directors appropriately.

<Disclosure Based on the Principles of the Corporate Governance Code (Excerpts)>

【Principle 1-4 Strategically held shares】

From the viewpoint of business expansion based on business alliance, etc. with business partners, we will acquire and hold the shares of the business partners, etc. if we judge that this will contribute to the improvement in our mid/long-term corporate value. The board of directors constantly check whether the holding of the above-mentioned shares (strategically held shares) will contribute to the improvement in our corporate value, and confirm the purpose and rationality of said holding based on that check. Our company will exercise the voting rights of the strategically held shares appropriately, based on comprehensive judgment from the viewpoint of improving our corporate value.

【Principle 1-7 Transactions among related parties】

Our company conducts a survey on transactions among executives and major shareholders every year, to check whether there are any transactions among related parties. In addition, our company produces a manual for producing financial statements, and if our company makes any transactions with executives, the employee shareholding association, major shareholders, or the like, the internal audit division, the administrative division, the board of directors, and the board of auditors will deliberate about the necessity of said transactions to a sufficient degree, so that said transactions will not harm the common interests of our company and shareholders.

【Principle 5-1 Policy on constructive dialogue with shareholders】

Regarding requests from shareholders for dialogue (interviews), our company believes that we should express a positive attitude within a reasonable scope in order to contribute to sustainable growth and medium- and long-term improvement of the corporate value of our company. Aiming to promote constructive dialogue with shareholders, with the planning department designated as a department in charge of IR activities, our company holds financial results briefings targeted at financial institutions and investors semiannually and discloses corporate information as needed on our website and through the system of optional disclosure offered by Tokyo Stock Exchange.

This report is intended solely for information purposes, and is not intended as a solicitation for investment. The information and opinions contained within this report are made by our company based on data made publicly available, and the information within this report comes from sources that we judge to be reliable. However, we cannot wholly guarantee the accuracy or completeness of the data. This report is not a guarantee of the accuracy, completeness or validity of said information and opinions, nor do we bear any responsibility for the same. All rights pertaining to this report belong to Investment Bridge Co., Ltd., which may change the contents thereof at any time without prior notice. All investment decisions are the responsibility of the individual and should be made only after proper consideration. Copyright(C) 2020 Investment Bridge Co., Ltd. All Rights Reserved. |