Bridge Report:(1433)BESTERRA the fiscal year ended January 2022

President Akitatsu Yoshino | BESTERRA CO., LTD (1433) |

|

Company Information

Market | TSE 1st Section (Newly established: Prime Market) |

Industry | Construction business |

President | Akitatsu Yoshino |

HQ Address | Kiba Park Bldg, 3-2-6 Hirano, Koto-ku, Tokyo, Japan |

Year-end | End of January |

Homepage |

Stock Information

Share Price | Share Outstanding (End of the term) | Market Cap. | ROE (Act.) | Trading Unit | |

¥1,190 | 8,750,400 shares | ¥10,412 million | 42.4% | 100 shares | |

DPS (Est.) | Dividend Yield (Est.) | EPS (Est.) | PER (Est.) | BPS (Act.) | PBR (Act.) |

¥20.00 | 1.7% | ¥54.40 | 21.9 x | ¥502.81 | 2.4 x |

*The share price is the closing price on March 28. Each number is from the financial results for the FY22/1.

Consolidated Earnings

Fiscal Year | Net Sales | Operating Income | Ordinary Income | Net Income | EPS | DPS |

Jan. 2019 (Actual) | 4,927 | 497 | 495 | 621 | 75.25 | 15.00 |

Jan. 2020 (Actual) | 3,436 | 93 | 97 | 59 | 7.29 | 16.00 |

Jan. 2021 (Actual) | 3,682 | 124 | 212 | 142 | 17.33 | 16.00 |

Jan. 2022 (Actual) | 5,966 | 607 | 840 | 1,467 | 174.54 | 16.00 |

Jan. 2023 (Forecast) | 6,700 | 620 | 666 | 469 | 54.40 | 20.00 |

* The forecasted values were provided by the company. Unit: million yen, yen.

This Bridge Report reviews on the outlook of BESTERRA CO., LTD’s earnings results for the fiscal year ended January 2022, its forecast of the fiscal year ending January 2023 and medium-term management plan.

Table of Contents

Key Points

1. Company Overview

2. Fiscal Year Ended January 2022 Earnings Results

3. Fiscal Year Ending January 2023 Earnings Forecasts

4. Progress of Medium-term Management Plan 2025

5. Conclusions

<Reference1: Medium-term Management Plan 2025>

<Reference2: Regarding Corporate Governance>

Key Points

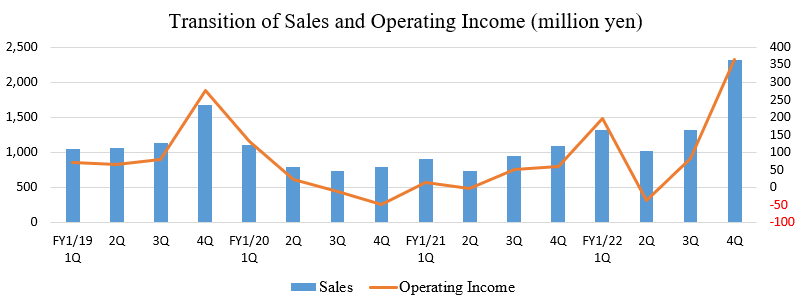

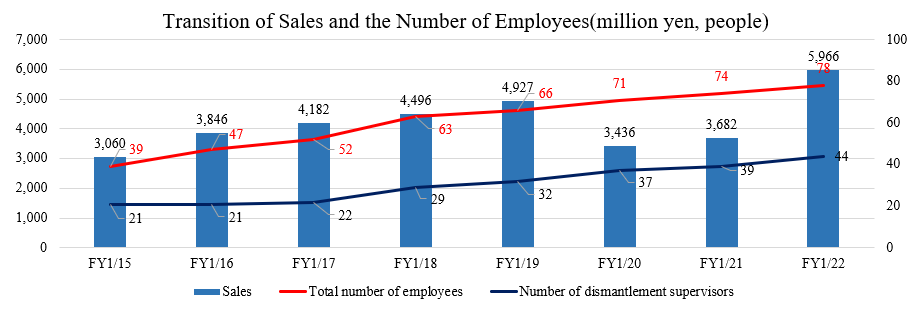

- In the term ended January 2022, sales increased 62.0% year on year to 5,966 million yen. Large-scale percentage-of-completion projects progressed smoothly, and business synergies with Yazawa Corporation, a new company of the corporate group, also contributed. Operating income increased 388.3% year on year to 607 million yen. The increase in sales, the contribution of high-margin construction works, and the boost of profit due to soaring scrap market prices offset the increase in SG&A expenses, including human resource investment and new windmill demolition method development costs in accordance with the medium-term management plan, resulting in a significant increase in profit. The company posted 201 million yen as equity in earnings of affiliated companies as a result of the conversion of Rever Holdings into an equity-method affiliate, and 1,275 million yen as gain on exchange of shares through the business combination of Rever Holdings as Rever Holdings and TAKEEI CORPORATION jointly transferred their shares and became subsidiaries of the newly established TRE Holdings. As a result, ordinary income increased 294.9% year on year to 840 million yen, and net income grew 929.7% year on year to 1,467 million yen. Both sales and profit exceeded the second revised forecast. Even on a quarterly basis, the fourth quarter (November-January) saw record sales and profit.

- For the term ending January 2023, the company forecasts a 12.3% year on year increase in sales to 6.7 billion yen and a 2.0% year on year increase in operating income to 620 million yen. The company expects the number of orders to remain firm. Due to the absence of equity in earnings of affiliates and exchange gains from business combination recorded in the previous fiscal year, ordinary income and net income are expected to decrease. The company plans to pay an interim dividend of 10 yen/share, up 4 yen/share, and a term-end dividend of 10 yen/share, unchanged from the previous year, for a total of 20 yen/share. The payout ratio is expected to be 36.8%.

- In the term ended January 2022, the first year of the "Mid-Term Management Plan 2025," the company steadily promoted the goals set forth in the Mid-Term Management Plan and exceeded the second upwardly revised figures. The company aims to continue steady progress in the second year and beyond.

- Originally, the company had planned a V-shaped recovery in the term ended January 2021, following significant declines in sales and profit in the term ended January 2020 due to delays in project orders and higher labor costs, but the COVID-19 pandemic delayed the recovery for a full fiscal year. However, we can highly evaluate the fact that the company's progress in expanding its human capital by hiring more demolition supervisors, which is necessary not only for the recovery but also for future growth, was in line with plans. Yazawa Corporation, which has become a subsidiary, is expected to contribute only to a certain extent to sales and profit, with expected sales of 700 million yen in 2023, but it is an important step forward in terms of expected synergies, such as the incorporation of key technologies and the use of customer bases.

- We expect the company to achieve a V-shape recovery and steadily expand its top line from this fiscal year onward. In addition, we will also pay close attention to the company's efforts and progress to further improve profitability while making aggressive investments.

1. Company Overview

As a specialist in plant dismantlement, BESTERRA manages the dismantlement of plants (metal structures) for iron-making, power generation, gas, petroleum, etc. Its core competence is “the method and technology for dismantling plants,” and it has many patented methods including international patents. The company concentrates its managerial resources on engineering (proposal, design, and work planning) and management (supervision and work management), and outsources actual dismantlement work to its affiliates, and so it does not own heavy machinery or construction teams (the risk of owning assets can be avoided), and it is unnecessary to procure materials, etc. and make transactions for material production (the inventory risk can be avoided).

The Group also has two consolidated subsidiaries, Hiro Engineering, which provides human resource services for design work, etc. and 3D Visual KK, which handles 3D scan modeling and design work.

The corporate name “BESTERRA” was coined by combining the English word “Best (the superlative of ‘good’)” and the Latin word “Terra (the earth),” and、infused with the ambition to “create the best earth.” By developing an integrated system for dismantling and recycling, the company aims to actualize an advanced recycling society and contribute to the earth environment.

Corporate ethos and the code of conduct

Under the corporate ethos “We will contribute to the earth environment with our flexible way of thinking, creativity, and technologies using these concepts,” the company enacted the following code of conduct.

The company has also established a "Basic Sustainability Policy" to contribute to the realization of a sustainable society.

◎ Basic Sustainability Policy

We, Besterra, are committed to both "realization of an advanced recycling-oriented society" and "sustainable corporate growth" based on our corporate philosophy of "We will contribute to the earth environment with our flexible way of thinking, creativity, and technologies using these concepts."

Long-term vision (Ideal state of the company)

・ Plant Demolition Leader in Japan

・ Proposing Plant Disassembly Technologies to the World

1-1 Characteristics of the business

The company has a single segment consisting of the plant demolition business. For others, it engages in the human resource service business and the 3D scan, modeling, and design business. In the term ended January 2021, the plant dismantling business accounted for 92.7% of total sales.

Plant dismantlement business

In the plant dismantlement business, the company works on all types of plants in the fields of ironmaking, electric power, gas, petroleum, and petrochemicals, etc. The company offers services on overall engineering processes including proposals, designing, work planning, outsourcing/arrangement of equipment and materials, supervision, safety management, cost management, financial management, and handling of governmental procedures. It focuses on designing its unique demolition technologies and supervising demolition works based on demolition plans and uses specialized subcontractors for demolition works.

The clients for plant dismantlement are leading companies that own plants for ironmaking, electric power, gas, petroleum, etc. In most cases, the equipment installation companies of the corporate groups of clients or leading general contractors are entrusted with dismantlement, and then BESTERRA serves as the primary or second-tier subcontractor.

Also, in the plant dismantlement business, BESTERRA receives valuable materials generated through dismantlement, such as scrap, and sells them to scrap handlers. Accordingly, the company estimates the value of valuable materials while comprehensively considering material, quantity, price (market price of each material, such as iron, stainless steel, and copper), etc. and negotiates with clients about the fee for dismantlement work. In accounting, the gain from sale of valuable materials is included in revenue from dismantlement work and posted as part of sales from completed dismantlement work. In some cases, contractors (clients) dispose of (sell) scrap, etc. by themselves.

*Two standards for posting revenue and seasonality of revenue posting of the company

The standards for posting revenue from contracts can be classified into the completed contract method, in which revenue is posted when works are completed, and the percentage-of-completion method, in which revenue is posted according to the progress of works. In the case of plant dismantlement, where valuables, such as scrap, are collected, revenue cannot be confirmed until the sale of scrap. Therefore, the company basically applies the percentage-of-completion method to large-scale projects whose contract amount exceeds 50 million yen and whose period exceeds 3 months, from the term ended January 2018 (the completed contract method is applied to the projects that are not applicable to the above criteria). The timing of posting revenue (the completion of demolition work) from works for which the completed contract method is used is often affected by the capital investment plans of clients. In the case of BESTERRA, revenue tends to be posted in the first quarter (February to April) and the fourth quarter (November to January) (the seasonality of revenue posting). However, the variation in quarterly performance may mislead investors, so the company is expanding the scope of application of the percentage-of-completion method step by step, to equalize the timings of revenue posting.

Others

In response to the chronic shortage of skilled construction workers, the company began providing human resource services in January 2013, and in March 2018, it made Hiro Engineering, which handles human resource services such as design work, a subsidiary. In January 2015, the company began offering a 3D measurement service as well. It established 3D Visual KK in December 2019, and 3D scan modeling and design business was transferred from INTER ACTION Corporation (securities code: 7725) in February 2020.

1-2 Strengths: an excellent client base, efficient dismantlement management based on plenty of experience, and intellectual property, such as patented methods

The strengths of the company are excellent client assets, efficient dismantlement management based on plenty of experience, and intellectual property, such as patented methods. Because the clients are basically engineering subsidiary companies of leading companies in ironmaking, electric, gas, coal oil fields, and major general contractors, which are easily trustable excellent clients, and it is predicted that they will receive orders continuously. The clients of the leading companies highly evaluate its company’s total management (low cost and high efficiency) of plant dismantlement that it cultivated experiences for over 40 years, and it elect a barrier to entry.

Furthermore, a variety of technologies and know-how the company possesses, which have been accumulated through environmental work, etc. is also the strength of the company, including the recycling of waste materials which is a manifest and potential intellectual property.

Patented methods, etc.

“Apple peeling demolition method” and fusing robot “Ringo☆Star”

The “apple peeling demolition method” is a method of dismantling a large spherical tank, such as gas holders and oil tanks, by cutting it in spirals from the center of the ceiling of the enclosure part. The cut part spirals down to the ground gradually under the force of the earth’s gravity (natural energy). The method enjoys superiority in a work period, cost, and safety, and has considerable competitive advantages, realizing “greater promptness, higher cost efficiency, and added safety.” Furthermore, the company offers a robot for the fusing process, “Ringo☆Star,” which automates the “apple peeling demolition method.” (The company is also working to expand the range of applications for “Ringo☆Star” by developing a new attachment).

Environment-related methods

The company has cultivated experiences and business results of a multitude of environment-related demolition works, using the “fireless methods” which do not require the use of fire. For example, although polychlorinated biphenyls (PCBs) are considered as a toxic substance and therefore totally abolished today, it had been used for many years in transformers and condensers because of its excellent thermal stability and chemical stability (electric insulation characteristics). In many cases, transformers and condensers are disposed of in conjunction with plant demolition works; however, because PCBs gasify when they are treated at the high temperature, posing a risk of inhaling the gas so generated, any firearms (such as gas cutting machines) cannot be used in demolition and withdrawal involving PCBs. The company is skillful at fireless and quasi-fireless methods using saber saws (which cut off objects with their saw blades moving in a reciprocating manner) that can cut off objects thicker than the thickness, which, in the industry, had been considered impossible to cut, through numerous devices, including measures against seizure of motors and recycling of blades. BESTERRA has applied for joint patents with Hitachi Plant Construction, Ltd. for a transformer dismantling method, a transformer dismantling jig, and a cutting device for dismantling a transformer.

Windmill demolition works

The number of power-generating wind turbines continues to increase by about 20% annually worldwide, but the demand for dismantling is expected to increase in the future due to wear and tear and economic obsolescence. According to the material presented by the company, the wind power generation volume worldwide is 486,790 MW (by about 340,000 onshore power generation plants and about 4,000 offshore ones) with an annual growth rate of about 20%. In Japan, the number of wind power generation plants stood at 2,225 as of the end of 2017, expanding by about 90 every year. Meanwhile, as the useful life is approximately 15 to 20 years, and the windmills for power generation established in the early stage are reaching the application limit. Moreover, not a few plants need to be dismantled due to damage or fatal failure caused by thunderbolts or typhoons.

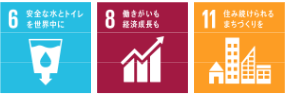

How to knock down a power-generating wind turbine (international patent application)

As some windmills have been built in mountain districts and on the sea, demolition of them is highly difficult. The company has devised a method for dismantling wind turbines that does not require scaffolds and has already acquired a domestic patent for “Method of knocking down a power-generating wind turbine.” International patents are pending for “Method of knocking down towering structures using their bases” and “Method for dismantling tower-shaped equipment for wind power generation.” Safety of workers can be improved dramatically, and the work period can be shortened by using these patent-based methods.

Pursuit of the value of the 3D business

Using services such as layout simulation, strain/bending/torsion measurement, comparison of structures before and after improvement, and video walkthroughs, the company converts physical data taken when plants were established (more than 30 years ago) into the latest 3D data and uses that to provide detailed information about the dismantling process. They also provide unique 3D measurement services for dismantling work using the latest measuring technology and simulation systems that are capable of drawing data as 2D diagrams, handling BIM/CIM modeling, Perfect 3D, and 3D printing, etc.

“Visualize” the dismantling process

Layout simulation | The equipment models produced with 3D CAD are placed in 3D data, and the replacement of equipment can be simulated. By moving the equipment models, it is possible to check how they interfere and collide with one another. |

Strain, bending, and torsion measurements | It is possible to measure changes in shapes. This is useful for diagnosing frameworks tentatively, to check whether a building got distorted due to an earthquake, deterioration, etc. |

Comparison of structures before and after installation

| The shapes of equipment that changes due to heat and vibration, such as pipes, conveyors, and furnaces, at the time of installation and after operation are compared. With 3D data, it is possible to grasp overall changes intuitively. |

Video walkthroughs

| Walk-through videos are produced by using synthesized point cloud data. These videos can be utilized for presentations and publicity videos regarding dismantlement plans and real estate information. |

Unique 3D measurement service

Draws a two-dimensional diagram | The 3D CAD models based on point cloud data are converted into drawings. It is also possible to produce drawings directly from point cloud data in a simple manner. |

Handles BIM/CIM modeling | Modeling is conducted with 3D CAD based on point cloud data. It is possible to produce models of the parts that require construction or renovation as BIM (building information modeling) data. |

Perfect 3D | This is a large-scale 3D data measurement service combining automobile-based MMS (mobile mapping system), airborne laser measurement, water area measurement, etc. |

3D printing | After modeling with point cloud data, data are processed and deformed so that they can be shaped with a 3D printer. It can produce fine structures with a lamination pitch of 15 μm. |

1-3 ROE analysis

| FY 1/18 | FY 1/19 | FY 1/20 | FY 1/21 | FY 1/22 |

ROE (%) | 11.7 | 23.8 | 2.3 | 5.6 | 42.4 |

Net Income to Sales Ratio (%) | 5.87 | 12.62 | 1.75 | 3.87 | 24.60 |

Asset Turnover Ratio(Times) | 1.11 | 1.08 | 0.72 | 0.67 | 0.79 |

Leverage(Times) | 1.80 | 1.75 | 1.85 | 2.14 | 2.17 |

The 42.4% in FY 1/22 was due to the recording of a 1.2 billion yen gain on exchange in the business combination. The company aims to achieve “an ROE of 13% in the term ending January 2026” in its “mid-term management plan 2025” (which will be described later).

2. Fiscal Year Ended January 2022 Earnings Results

2-1 Consolidated results

| FY 1/21 | Ratio to sales | FY 1/22 | Ratio to sales | YoY | Forecast ratio |

Sales | 3,682 | 100.0% | 5,966 | 100.0% | +62.0% | +1.1% |

Gross profit | 732 | 19.9% | 1,357 | 22.7% | +85.2% | - |

SG&A expenses | 608 | 16.5% | 749 | 12.6% | +23.2% | - |

Operating income | 124 | 3.4% | 607 | 10.2% | +388.3% | +3.0% |

Ordinary income | 212 | 5.8% | 840 | 14.1% | +294.9% | +1.3% |

Net income | 142 | 3.9% | 1,467 | 24.6% | +929.7% | +0.7% |

*Unit: million yen. Net income is net income attributable to owners of the parent company. Forecast ratios are ratios to the forecasts announced in February 2022.

Significant increase Record sales and profits were recorded. Forecasts also exceeded.

Sales increased 62.0% year on year to 5,966 million yen. Large-scale construction projects under the percentage-of-completion method progressed smoothly, and business synergies with Yazawa Corporation, a new addition to the group, also contributed to sales.

Operating income rose 388.3% year on year to 607 million yen. The increase in sales, contribution from high-margin construction projects, and soaring scrap prices boosted profits, which offset higher SG&A expenses, including human resource investment based on the medium-term management plan and development costs for new windmill demolition projects, resulting in a significant increase in profits.

In addition to posting equity in earnings of 201 million yen from the conversion of River Holdings Corporation into an equity-method affiliate, River Holdings Corporation conducted a joint share transfer with Takeei Co. Ltd. became a subsidiary of TRE Holdings, Inc., the Company recorded an exchange gain of 1,275 million yen on the business combination of River Holdings, Inc. Net income increased 929.7% year on year to 1,467 million yen.

Both sales and profits exceeded the second revised forecast.

On a quarterly basis, Q4 (Nov.-Jan.) sales and profits reached record high.

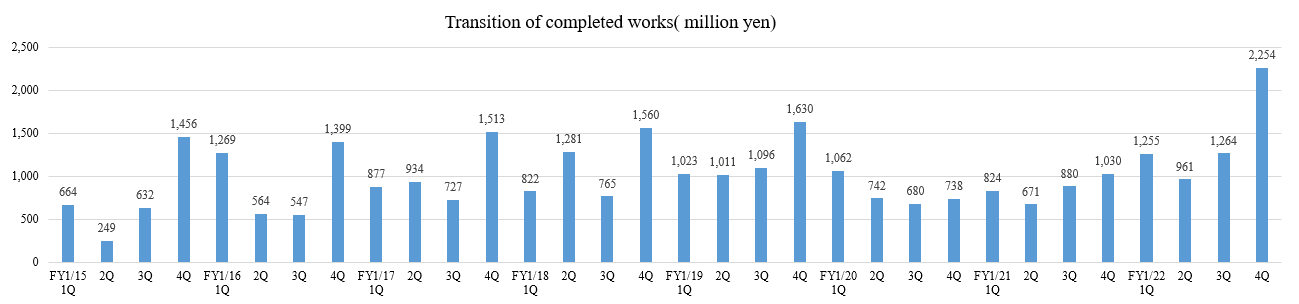

The number of completed works (rough estimates)

| FY 1/21 | Ratio to sales | FY 1/22 | Ratio to sales | YoY |

Electric power | 615 | 18% | 1,205 | 21% | +96% |

Steelmaking | 1,263 | 37% | 975 | 17% | -23% |

Petroleum/petrochemical | 1,161 | 34% | 2,008 | 35% | +73% |

Gas | 68 | 2% | 57 | 1% | -16% |

3D | 102 | 3% | 115 | 2% | +12% |

Environment |

| - | 1,205 | 21% | - |

Others | 205 | 6% | 172 | 3% | -16% |

Total | 3,414 | 100% | 5,736 | 100% | +68% |

*Unit: million yen

"Environment-friendly work (dioxin, asbestos, soil contamination, etc.)," which was previously included in the "other" category, is now shown as a new category. The ratio of environment-related improvement works increased with the reorganization of Yazawa Corporation, which possesses advanced asbestos removal technology, into a subsidiary.

Both full-year and fourth-quarter sales reached record highs. Due to the seasonality of customers' (clients') capital investment plans. In past years, the company tends to be anticipating an increase in the amount of completed works in the second half.

Breakdown of SG&A

| FY 1/21 | Ratio to sales | FY 1/22 | Ratio to sales | YoY

| Major change factors |

Personnel cost | 333 | 9.0% | 434 | 7.3% | +30.3% | Increase in headcount of main employee and bonuses |

R&D cost | 9 | 0.2% | 13 | 0.2% | +51.4% | The development of dismantling methods for wind power generation facilities |

Commissions and remunerations paid | 64 | 1.7% | 69 | 1.2% | +8.3% | - |

Recruitment cost | 13 | 0.4% | 24 | 0.4% | +80.1% | Personnel increase |

Advertisement | 4 | 0.1% | 8 | 0.1% | +85.8% | Branding |

Others | 183 | 5.0% | 198 | 3.3% | +8.2% | - |

Total SG&A expenses | 608 | 16.5% | 749 | 12.6% | +23.2% | - |

*Unit: million yen

The company aggressively made investments for growth, including human resource investments based on its medium-term management plan, development costs for new windmill demolition work methods, and corporate brand development costs to receive orders as prime contractors.

As a result of aggressive hiring activities based on the personnel strategy in the mid-term management plan, the number of demolition supervisors exceeded the 43 set in the initial plan, and reached 44, up 5 from the beginning of the term.

2-2 Orders received and the backlog of orders

| FY 1/21 | FY 1/22 | YoY |

The backlog of orders at the beginning of the term | 1,046 | 2,545 | +143.1% |

The amount of works received | 4,912 | 4,785 | -2.6% |

The amount of completed works | 3,414 | 5,736 | +68.0% |

The backlog of orders at the end of the term | 2,545 | 1,594 | -37.4% |

*Unit: million yen

Orders received remained steady. The number of promising projects for which orders are expected to be received is increasing as a result of aggressive approaches to prime contractors. The number of inquiries from all industries is healthy.

Orders received by sector (Amounts are approximate.)

| FY 1/21 | Ratio | FY 1/22 | Ratio | YoY |

Electric power | 814 | 32% | 271 | 17% | -67% |

Steelmaking | 382 | 15% | 383 | 24% | +0% |

Petroleum/petrochemical | 1,145 | 45% | 622 | 39% | -46% |

Gas | 76 | 3% | - | - | - |

Environment | - | - | 255 | 16% | - |

Other | 127 | 5% | 64 | 4% | -50% |

Total order received | 2,545 | 100% | 1,594 | 100% | -37% |

*Unit: million yen

The ratio of environment-related improvement works has increased thanks to the acquisition of Yazawa Corporation as a subsidiary. The composition of the company is well-balanced across all industries.

2-3 Financial condition and cash flow(CF)

Financial condition

| January 2021 | January 2022 |

| January 2021 | January 2022 |

Cash | 1,367 | 2,122 | Payables | 558 | 1,199 |

| Notes receivable, accounts receivable from completed construction contracts and other | 1,392 | 2,212 | Borrowings and Bonds | 2,519 | 2,389 |

Current Assets | 2,948 | 4,561 | Liabilities | 3,435 | 4,665 |

Investments, Others | 2,765 | 3,905 | Net Assets | 2,595 | 4,354 |

Noncurrent Assets | 3,082 | 4,458 | Total Liabilities, Net Assets | 6,030 | 9,020 |

*Unit: million yen

Total assets increased 2,989 million yen from the end of the previous term to 9,020 million yen, mainly due to an increase in cash. Total liabilities increased 1,230 million yen from the end of the previous term to 4,665 million yen, mainly due to an increase in payables. Net assets increased 1,759 million yen from the end of the previous term to 4,354 million yen due to an increase in retained earnings. Capital-to-asset ratio increased 5.1 points from the end of the previous term to 48.1%.

Cash Flow(CF)

| FY 1/21 | FY 1/22 | YoY |

Operating Cash Flow(A) | -108 | 537 | +646 |

Investing Cash Flow(B) | -101 | -32 | +68 |

Free Cash Flows (A + B) | -209 | 505 | +714 |

Financing Cash Flow | 638 | 250 | -388 |

Cash and Equivalents at Term End | 1,367 | 2,122 | +755 |

*Unit: million yen

Operating CF and free CF turned positive, mainly due to an increase in quarterly income before taxes and other adjustments. The cash position improved.

2-4 Topics

(1) Prepared a plan to comply with the criteria for remaining listed in the new market segment.

In November 2021, the company resolved to select the prime market as the new market classification of the Tokyo Stock Exchange, Inc. will become effective in April 2022, and submitted an application for market selection on the same day. However, as of the transition reference date (June 30, 2021), the market capitalization of tradable shares was 7.55 billion yen, which did not meet the 10 billion yen listing maintenance standard for this market, so the company prepared a plan to comply with the listing maintenance standard for the new market segment.

By the term ending January 2026, the company aims to meet the criteria for maintaining its listing on the prime market by implementing various measures to fulfill the criteria for maintaining listing based on the Mid-term Management Plan 2025.

For details, please refer to the company's website.

https://ssl4.eir-parts.net/doc/1433/tdnet/2050149/00.pdf

(2) Nomination and Compensation Committee established

In December 2021, the Nomination and Compensation Committee was established.By establishing this committee, which is an advisory body to the Board of Directors, the company aims to ensure the fairness, transparency, and objectivity of the decision-making process regarding the nomination and compensation of directors, etc., and to further enhance and strengthen its corporate governance system.

The Committee shall consist of three or more directors selected through the resolution of the Board of Directors, a majority of whom shall be independent outside directors. In addition, a chairman shall be selected from the members of the independent outside directors appointed as committee members by a resolution of said committee.

(3) Set the "Basic Sustainability Policy" and established the "Sustainability Committee"

In December 2021, the company set the "Basic Sustainability Policy" to contribute to the realization of a sustainable society and established the "Sustainability Committee" to oversee and manage this policy.

【Basic Sustainability Policy】

We, Besterra, are committed to both "realization of an advanced recycling-oriented society" and "sustainable corporate growth" based on our corporate philosophy of "We will contribute to the earth environment with our flexible way of thinking, creativity, and technologies using these concepts."

The Sustainability Committee shall be chaired by the Chairman of the Board and its members shall consist of full-time directors.

3. Fiscal Year Ending January 2023 Earnings Forecasts

3-1 Full-year consolidated earnings forecast

| FY 1/22 Act. | Ratio to sales | FY 1/23 Est. | Ratio to sales | YoY |

Sales | 5,966 | 100.0% | 6,700 | 100.0% | +12.3% |

Operating income | 607 | 10.2% | 620 | 9.3% | +2.0% |

Ordinary income | 840 | 14.1% | 666 | 9.9% | -20.8% |

Net income | 1,467 | 24.6% | 469 | 7.0% | -68.1% |

*Unit: million yen

Sales and operating income are predicted to increase

Sales are expected to increase 12.3% year on year to 6.7 billion yen, and operating income is projected to rise 2.0% year on year to 620 million yen. The company expects orders to be firm. Ordinary income and net income are expected to decrease due to the absence of equity in earnings of affiliates and exchange gains from business combinations, which were recorded in the previous fiscal year. The company plans to pay an interim dividend of 10 yen per share, up 4 yen per share, unchanged from the previous year, for a total of 20 yen per share. The expected payout ratio is 36.8%.

4. Progress of Medium-term Management Plan 2025

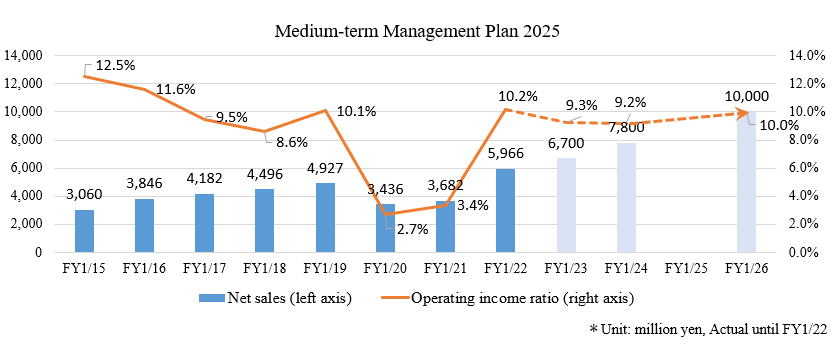

The company is executing the 5-year “mid-term management plan 2025 (FY 1/22 to FY 1/26),” which starts January 2022.

(1) Review of the first fiscal year

(1) Quantitative Plan

The company made two upward revisions, but the results exceeded them.

| FY 1/21 initial plan | FY 1/22 Act. | Rate of achievement | Change from Revised Forecast |

Sales | 5,600 | 5,966 | +6.6% | +1.1% |

Gross profit | 1,200 | 1,357 | +13.1% | - |

SG&A expenses | 750 | 749 | -0.1% | - |

Operating income | 450 | 607 | +35.1% | +3.0% |

Ordinary income | 518 | 840 | +62.2% | +1.3% |

Quarterly net income | 360 | 1,467 | +307.8% | +0.7% |

*Unit: million yen. Net income is net income attributable to owners of the parent company. Forecast ratios are ratios to the forecasts announced in February 2022.

(2) SG&A expenses

As mentioned above, the company aggressively made investments for growth, including human resource investments based on its medium-term management plan, development costs for new windmill demolition works, and corporate brand development costs to receive orders as a prime contractor. The advertising expenses were 50% of the estimate because the exhibition could not be held because of the pandemic.

Breakdown of SG&A expenses

| FY 1/21 Plan | FY 1/22 Act. | Rate of achievement |

Personnel expenses | 407 | 434 | +6.5% |

Research and development expenses | 14 | 13 | -0.6% |

Commissions and fees paid | 70 | 69 | -0.8% |

Recruitment expenses | 19 | 24 | +25.1% |

Advertising expenses | 16 | 8 | -49.6% |

Other | 222 | 198 | -10.6% |

Total SG&A expenses | 750 | 749 | -0.1% |

*Unit: million yen

(3) Qualitative Plan

The following measures were actively promoted.

| Details of implementation |

Technology Patent Strategy | ・Decarbonized demolition initiatives ・Development of wind power generation equipment dismantling methods |

Sales Strategy | ・Expansion of orders as a prime contractor ・Strengthening of corporate brand development ・Enhancement of bases |

Strengthening of the Work Management System | ・To complete the personnel plan |

Management Strategy | ・Environmental management initiatives ・To strengthen the corporate governance structure ・M&A investment using procured funds (Phase 1: Yazawa Corporation) |

◎Decarbonized Dismantlement Initiatives

The company is developing demolition methods that take into account environmental aspects in order to achieve a sustainable society (SDGs). All of the following methods do not use large heavy machinery, do not use fuel, and use natural energy (gravity). They ensure a high level of safety, reduce costs due to shorter project periods, and significantly reduce greenhouse gas emissions.

Method | Outline | Period | CO2 emissions | Cost |

Apple Peeling Method

| In dismantling spherical storage tanks such as gas holders and oil tanks, this method involves cutting from the center of the outer ceiling in a spiral shape, just like peeling an apple. | Approx. 65% shortening | Approx. 50% reduction | Approx. 65% reduction |

Tipping over method | In wind power generation facilities, the tower foundation (concrete portion) is cut and turned over. The axis of tipping over is clear, allowing precise control of the tipping-over direction. | Approx. 10% shortening | Approx. 40% reduction | Approx. 45% reduction |

◎Development of a method for dismantling wind power generation facilities

Wind power generation output in the world is about 490,000 MW per year and growing by about 20% annually. In Japan, 2,225 wind power generation facilities had been installed by the end of 2017, with an annual increase of about 90 units.

On the other hand, the service life is about 15 to 20 years, and the windmills installed in the early years for power generation are reaching the end of their useful life. In addition, it is assumed that a significant number of units need to be dismantled due to damage or catastrophic failures caused by lightning strikes, typhoons, and other factors.

Against the backdrop of this increased demand for dismantling wind power generation equipment and the expansion of the environmentally friendly natural energy business, they have developed a dismantling method ahead of their competitors as a patented method. Demonstration tests of the tipping method were conducted in Akita Prefecture and the Goto Islands in Nagasaki Prefecture.

◎Expansion of orders as a prime contractor

The percentage of orders for prime contracting work from client manufacturers is increasing due to the improvement of reliability and technical capabilities. The increase in the ratio of prime contracting projects is a sign of a stronger customer base and is linked to higher profit margins.

◎To strengthen corporate brand development

To enhance corporate value (brand power), the company is enhancing its advertising tools and promoting effective corporate brand development through various media.

Specifically, the company is sending a unified message to all stakeholders through the appointment of the Judo master Kosei Inoue as an ambassador, an appearance on NHK's TV program "Kaitai Kingdom," and the release of a video of dismantling method.

◎Enhancement of bases

In order to increase orders for recurring-revenue projects (projects with continuous orders from customers and stationed work within the same premises), an office was newly established in Kitakyushu City, Fukuoka Prefecture, near the Kitakyushu factory area. In addition, the West Japan Office (Fukuyama) was relocated (expanded).

Preparations are underway to open offices in Kashima and Kurashiki, and the company is considering opening another in Sendai.

◎Completion of the staffing plan

In order to reap the benefits of market growth, it is essential to expand the hiring of demolition supervisors.

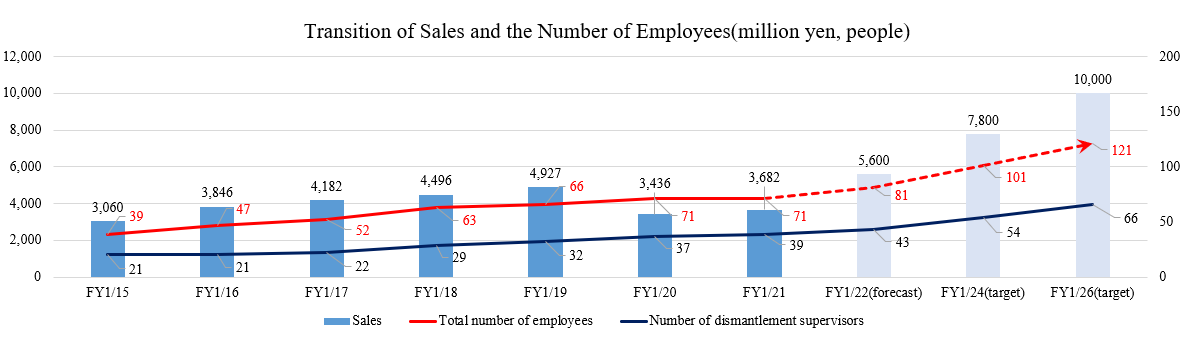

As a result of company-wide recruiting efforts, the company hired 5 supervisors in the term ended January 2022, achieving the target number of supervisors (43). For the term ending January 2023, the company plans to hire at least 6 more supervisors, aiming to achieve the term ending January 2024 target of 56, ahead of schedule.

◎Environmental Management Initiatives

The company recognizes that mitigating climate change and contributing to the transition to a decarbonized society and its realization is a corporate responsibility and an important management issue. Through activities to reduce energy consumption, the company will reduce greenhouse gas emissions and contribute to the mitigation of climate change.

Specific actions are as follows.

Action | Overview |

Company Vehicles | 14 HV-spec vehicles were introduced. Compared to gasoline-powered vehicles, each HV vehicle reduces CO2 emissions by approximately 43% per month, which is equivalent to reducing the amount of CO2 absorbed by approximately 1,200 cedar trees per year. |

Lighting | All the main lighting was replaced with LEDs. The CO2 reduction rate is approximately 60% per year, which is equivalent to the reduction of CO2 absorbed by approximately 700 cedar trees per year. In addition to frequently turning off lights in unused meeting rooms, etc., the company also makes sure that all lights are turned off when leaving the office. |

In-house system | The company is promoting a paperless office environment and telework, including the adoption of a cloud billing service. |

PCs and OA equipment | All PCs and OA equipment are turned off when leaving the office. The company promotes setting PCs to the energy-saving mode. |

Air conditioning | In addition to frequently turning off the air conditioning when not in use, the use of after-hours air conditioning is being reduced and circulators are being used to improve cooling efficiency. |

◎Strengthening of the corporate governance system

The company responded to the revised governance code and established the Sustainability Committee and the Nomination and Compensation Committee to further strengthen its corporate governance structure.

It aims to further enhance its corporate value toward the realization of a sustainable society.

◎M&A investment using procured funds

With the funds raised through the exercise of the 9th series of stock acquisition rights, the company succeeded in reorganizing Yazawa Corporation into a subsidiary of the Company.

Yazawa Corporation provides Japan's top-class special technologies for asbestos and dioxin countermeasures, as represented by the "Yazawa Asbestos Removal Method," and has received many orders for urban redevelopment projects, with major general contractors as its main customers.

The company's goals in acquiring this company are: to capture Yazawa's strong order backlog (several projects in central Tokyo); occupy the asbestos removal market and increase unit prices by offering package solutions; and to expand contacts with prime contractors.

As in the case of Yazawa, the company aims to increase its corporate value by pursuing M&A to bring key technologies in-house in the following four areas, which have high synergy effects with plant dismantling technologies.

The amount of investment is up to 2.5 billion yen over four years.

Areas related to decommissioning of facilities for decarbonization |

Areas related to the dismantling of wind power facilities |

Digital-related fields for pursuing 3D business value |

Specialized fields aimed at upgrading demolition techniques |

(2) Five-year quantitative plan

In the first fiscal year, the term ended January 2022, the company achieved results that far exceeded the planned figures. The company will continue to steadily achieve its goals in the second year and beyond.

In the long term, the company aims to achieve sales of 100 billion yen and an operating income of 10 billion yen, and a 10% share of the plant dismantling market.

| FY1/21 | 1st year FY 1/22 (Goal) | 1st year FY 1/22 (Act) | 2nd yearFY 1/23

| 3rd year FY 1/24

| 5th year FY 1/26

| CAGR |

Sales | 3,682 | 5,600 | 5,966 | 6,700 | 7,800 | 10,000 | +22.1% |

Operating income | 124 | 450 | 607 | 620 | 720 | 1,000 | +51.8% |

Ordinary income | 212 | 518 | 840 | 666 | 794 | 1,072 | +38.3% |

Net income | 142 | 360 | 1,467 | 469 | 552 | 752 | +39.6% |

Operating income margin | 3.4% | 7.9% | 10.2% | 9.3% | 9.2% | 10.0% | - |

ROE | 5.6% | 12.3% | 42.4% | 10.1% | 12.5% | 13.0% | - |

EPS | 17 | 43 | 174 | 54 | 67 | 91 | +39.9% |

*Unit: million yen, yen.

*CAGR (1) is the average annual growth rate from FY 1/21 to FY 1/26, and CAGR (2) is the average annual growth rate from FY 1/22 to FY 1/26, calculated by Investment Bridge Co., Ltd.

5. Conclusions

Originally, the company had planned a V-shaped recovery in the term ended January 2021, following significant declines in sales and profit in the term ended January 2020 due to delays in project orders and higher labor costs, but the COVID-19 pandemic delayed the recovery for a full fiscal year. However, we can highly evaluate the fact that that the company's progress in expanding its human capital by hiring more demolition supervisors, which is necessary not only for the recovery but also for future growth, was in line with plans. Yazawa Corporation, which has become a subsidiary, is expected to contribute only to a certain extent to sales and profit, with expected sales of 700 million yen in 2023, but it is an important step forward in terms of expected synergies, such as the incorporation of key technologies and the use of customer bases. We expect the company to achieve a V-shaped recovery and steadily expand its top line from this fiscal year onward. In addition, we will also pay close attention to the efforts and progress made to further improve profitability while making aggressive investments.

<Reference1: Medium-term Management Plan 2025>

① Ideal state and long-term vision

Besterra aims to flourish in the global market as the “plant demolition leader in Japan” and the “enterprise that proposes the plant dismantling technology to the world” based on its technologies and know-how.

To attain this goal, the company pursues “Besterra ESG management.” In detail, it will implement the five strategies: the “technological patent strategy,” “sales strategy,” “strengthening of the dismantlement management system,” “digital transformation (DX),” and “management strategy.”

② Besterra ESG management and SDGs

◎ Besterra ESG management

Under the corporate ethos: “to contribute to the earth environment with flexible thinking and creativity and technological capacity based on them,” the company aims to contribute to social sustainability and achieve beneficial growth. This is “Besterra ESG management,” and its unique business model for gaining competitive advantages.

The company will concentrate on the following five items, with the measures or policies of “SDGs of Besterra,” “enhancement of non-financial strategies and initiatives,” and “establishment of a growth model from the long-term viewpoint.”

Personnel | Pursuit of worthwhile jobs and individual growth |

Safety | Creation of a safety culture with its unique technologies |

R&D | Development of innovative demolition methods friendly to the earth |

Recycling | Realization of advanced environmental cycling through the strengthening of the venous industry |

Governance | Thorough transparency and risk control |

◎ SDGs of Besterra

For contributing to the earth environment, the company set a total of 17 goals related to SDGs and aims to attain them.

1 | To contribute to the earth environment by offering innovative dismantling technologies | ① To offer innovative dismantling technologies for deteriorated infrastructure ② To offer reliable, safe dismantling technologies for a low-carbon society and contribute to the earth environment ③ To offer advanced dismantling technologies as a professional in dismantlement by utilizing 3D technologies |

|

2 | To develop a working environment in which employees can feel that their jobs are worthwhile | ① To become a company in which every employee can feel that their job is worthwhile and be proud of the future ② To respect diversity and enrich the fair environment ③ To develop a fair educational environment where it is possible to exert abilities to the maximum |

|

3-1 | To realize an advanced recycling-oriented society and contribute to the establishment of a sustainable society | ① To dispose harmful materials and pollutants appropriately and offer technologies for making them harmless ② To develop a recycling business with high added value and improve productivity ③ To coexist with local communities and contribute to the improvement of local environments |

|

3-2 | To foster partnership for establishing a sustainable (advanced recycling) society | ① To foster future-oriented partnership with lofty goals beyond all kinds of boundaries ② To promote fair and equitable partnership between enterprises ③To offer new technologies, knowledge, and findings to the advanced recycling society, to attain goals |

|

③ Strategies

The outline of the five strategies: “technological patent strategy,” “sales strategy,” “strengthening of the dismantlement management system,” “digital transformation (DX),” and “management strategy” is as follows.

③-1 Technological patent strategy

The company has obtained a lot of patents regarding tanks, boilers, chimneys, etc., and will keep acquiring competitive patents for dismantlement methods in the fields of windmills, wind power generation, etc., where demand is expected to grow, and propose original demolition methods and put them into practice.

While the global demand for windmills for power generation is growing at an annual growth rate of about 20%, the demand for dismantlement is projected to rise, due to the expiration for use and economic obsolescence.

In order to meet the growing demand for dismantlement of wind power generation equipment, the company has applied for a patent for the dismantlement method “Matryoshka Method” and "Tower crane method" and "tipping method" ahead of competitors.

The technological development division is in charge of development of dismantlement methods for obtaining patents and has a system for developing methods based on ideas collected from on-site staff. Demonstration tests of the tipping method were conducted in Akita Prefecture and the Goto Islands in Nagasaki Prefecture.

Reference: Patent construction method video

https://www.besterra.co.jp/technology/movie.html

(Source: The company)

Since harmful substances are used at each plant equipment, soil pollution is an issue. Through the amendment into the Soil Contamination Countermeasures Act, it became necessary to conduct a soil survey when developing land with an area of 900 m2 or larger (before the amendment: 3,000 m2 or larger) in April 2019.

They will respond to the growth of such needs.

③-2 Sales strategy

In detail, the company will work on the “increase of orders received as a main contractor,” “enhancement of corporate brand development,” “cementing of cooperation,” and “upgrade of business bases.”

◎ Increase of orders received as a main contractor

The company aims to boost earnings ratio by increasing direct orders and the ratio of directly commissioned works and public works.

Since Besterra proposes plans based on each client’s plan, it possesses the knowledge of how directly commissioned works are carried out, but in order to fortify the system, it will adopt the system for obtaining qualifications, including those for supervising engineers, increase marketing support staff, and reform the personnel system.

◎ Enhancement of corporate brand development

In order to effectively enhance its brand power, the company will enrich advertising tools and distribute unified messages to stakeholders via the media, etc.

◎ Cementing of cooperation

The company will cement corporation in various ways.

*Cementing of cooperation with group companies

The company offers human resources services and 3D measurement services via subsidiaries. It will pursue business synergy by cementing cooperation among group companies and offering services through group marketing.

*Cementing of cooperation with alliance partners

The company will cement cooperation for decommissioning nuclear power plants.

Besterra will serve as a platform, and alliance partners, such as Hitachi Plant Construction, Ltd. (business alliance formed in July 2018), Daiichi Cutter Kogyo K.K. (business alliance formed in September 2018), and Rever Holdings Corporation (business alliance formed in September 2019), will conduct cooperative activities while utilizing each other’s strengths, to establish a system for decommissioning business.

In Japan, there are 60 nuclear reactors at 19 locations, but 24 reactors out of them are to be decommissioned. The examination on the compliance with the new standards will progress, and the decommissioning business is expected to grow. Actually, business inquiries are reportedly increasing.

*Cementing of cooperation with Rever HD

The company will cement the cooperation with Rever Holdings Corporation, which is an equity-method affiliate.

While the core business of Besterra is the dismantlement of plants, which is positioned between the arterial industries including “electric power, iron-making, and petroleum/petrochemical ones” and the venous industries including “scraps and industrial waste,” the core business of the Rever Holdings Group is the intermediate processing in the venous industries including “scraps and industrial waste.”

While responding to the deterioration of infrastructure, whose market is expected to grow, the two companies will fulfill the role of linking the arterial and venous industries and establish an indispensable position in the advanced recycling society.

*Rever Holdings Corporation integrated with TAKEEI CORPORARION to establish a joint holding company, TRE Holdings, on October 1, 2021.

◎ Upgrade of business bases

In order to increase orders for recurring-revenue projects (such as continuous orders from clients, works that require supervisors always staying, the apple peeling dismantlement method, and PCB treatment works), the company will consider the establishment of new business bases in Kurashiki, where the amount of dismantlement projects is large, industrial complexes in Kashima, etc., Sendai, etc.

③-3 Strengthening of the dismantlement management system

*Improvement of the procurement system

The company used to outsource works at each site for swift management, but seeing the expansion of the corporate scale, the newly established procurement division of the headquarters has adopted a cost control system. It aims to optimize procurement costs by outsourcing works all at once.

*Staffing plans

As the company specializes in dismantlement management, it needs to deploy a supervisor for all works. For sustainable growth, it is indispensable to increase dismantlement supervisors, so it will engage in company-wide recruitment activities.

*Development of a personnel training system

In order to cope with the chronic shortage of manpower, the company will develop “a program for producing advanced dismantlement engineers” to increase the number of employees who will drive business growth and make them useful early.

“Program for producing advanced dismantlement engineers”

The company will implement the “training program” for realizing the transfer of techniques from experienced engineers to inexperienced ones.

In addition, it will “introduce a course for specialists in dismantlement and a course for managers” and “enrich the system for promoting the acquisition of qualifications” for producing dismantlement supervisors, and formulate and operate a personnel system, which is focused on the workstyles of individuals.

*Cementing of cooperation with subcontractors

Actual dismantlement works are conducted by subcontractors, and Besterra supervises and manages on-site work. Subcontractors are groups of engineers who take central roles in dismantlement works. Accordingly, Besterra aims to improve the quality of works by cementing the cooperation with them.

Besterra makes transactions with a hundred and several tens of subcontractors per year. They are composed of a broad range of companies, including dismantling firms, companies that lease or rent heavy machinery, equipment, etc., and companies that process scraps and industrial waste. Among subcontractors around Japan, only about 30 companies possess the technology required for Besterra’s works, so Besterra entrust them even if the site is distant.

With the dismantlement plan designed by Besterra, the dismantlement process is optimized, and a high profit margin is actualized. Besterra pays to subcontractors within about 35 days after the closing date of a transaction, while clients pay within about 105 days after the closing date of a transaction. This is a merit in cash management for subcontractors undertaking the works of Besterra.

*Acquisition of essential technologies through M&A, etc.

The company will encourage enterprises that possess essential technologies for the processes such as preliminary surveys, planning, dismantlement, disposal of waste, and ground leveling to join the Besterra Group through M&A or the like and acquire advanced technologies.

③-4 Promotion of DX

By utilizing data and digital technologies, the company will upgrade products, services, and business models, and reform its business operations, organizations, processes, corporate culture, and climate, to establish a competitive advantage.

*Crane rail inspection robots and revision to inspection methods

In order to efficiently conduct regular inspection of overhead cranes, which are installed at plants and factories to convey heavy objects and parts, the company has developed a self-propelled inspection robot that runs on a crane rail in cooperation with iXs Co., Ltd.

A distortion of an overhead crane caused by deterioration due to aging would lead to a serious accident if it were not dealt with, so the regulations on safety of cranes, etc. in the Industrial Safety and Health Act stipulates that an enterprise that has installed a crane shall inspect it voluntarily once a month and once a year.

In the conventional manual inspection, workers had to go to the ceiling. Accordingly, there was a risk of an accident, visual inspection led to inconsistency, and the loss of opportunities occurred due to the suspension of factory operation.

Meanwhile, inspection robots can reduce the risk of accidents among workers, always obtain accurate, meticulous data, and complete inspection in a short period of time or in a spare time.

Besterra estimates that the market scale is about 30 billion yen.

*Reform of design and dismantlement processes

By converting paper data at the time of construction (over 30 years ago) into cutting-edge 3D data, the company will conduct dismantlement whose processes are “visualized.”

*Streamlining of on-site work based on the collaboration between people and robots

The company will use people and robots together at dismantlement sites while combining technologies for 3D measurement, dismantlement, and robot control.

③-5 Management strategy

*Environment

The company will contribute to the environment-oriented business administration of each client, by actualizing environment-oriented business administration itself and providing dismantlement technologies for revamping plant equipment that would produce high environmental burdens.

*Reform of workstyles and development of a system for working without worry

The company has adopted various systems so that employees can work with peace in mind for a long period of time. It will make efforts to increase the retention rate of employees and utilize the systems for recruitment.

(Concrete examples)

・Income insurance: The company will fully bear the insurance premiums. 50% of monthly pay will be covered until the age of retirement (60 years old). It is one of the best income insurances in Japan.

・ Retirement benefit system

・ Employee shareholding association: The company bears 15% of the reserve for members.

・ Retainable annual paid holidays: Paid holidays can be generally retained for 40 days as set forth in the Labor Standards Act, but in the company, it can be retained for up to 80 days in case an employee’s needs to recover from an injury or a disease.

*Governance

In order to actualize a system for achieving profitable growth and a sustainable society, the company will tighten its corporate governance.

④ Fundraising

As mentioned above, the company has procured funds by issuing share acquisition rights for the purposes of securing funds for growth and fortifying its financial foundation for completing the Mid-term Management Plan.

⑤ Distribution of profits and return to shareholders

With regard to the distribution of net income, the company set the policies: (1) “investment for future growth,” (2) “internal reserve for strengthening the business base,” and (3) “return of profit to shareholders targeting a payout ratio of 40%.”

For growth, the company allocates funds rationally according to situations to the investment in human resources (recruitment and education), the investment in technological development (dismantlement methods and robots), the investment in systems (3D systems, BIM and CIM), and the investment in strategic business (M&A).

<Reference2: Regarding Corporate Governance>

◎ Organization type and the composition of directors and auditors

Organization type | Company with a board of company auditors |

Directors | 8 directors, including 2 outside ones |

Auditors | 3 auditors, including 3 outside ones |

◎ Corporate Governance Report Update date: April 23, 2021

Basic policy

In order to promote sound business administration and win social trust sufficiently, our company recognizes corporate governance as the most important issue, puts importance on the improvement of the soundness, transparency, and fairness of business administration, and complies with laws and regulations thoroughly, and all executives operate business while keeping in mind that “the violation of laws or regulations would lead to management responsibility.” In detail, our company disseminates and executes business pursuant to laws, regulations, and in-company rules thoroughly, by developing appropriate systems for making decisions about business administration, fulfilling duties, supervising work, conducting internal control, etc.

It is also important to reform management systems for “achieving appropriate share price” and “increasing share price sustainably” to emphasize shareholders and strengthen the function to check business administration, to establish global-level corporate governance. The results of such efforts would win the trust of society, increase corporate value, and satisfy shareholders.

<Reasons for Non-compliance with the Principles of the Corporate Governance Code (Excerpts)>

【Supplementary principle 4-3-3】

Our company has not established a clear procedure ensuring objectivity, timeliness, and transparency for dismissal of the president or CEO, but we strive to realize a mutual assessment by involving outside directors in the process of evaluation of nomination and remuneration of the Board of Directors, in order to carry out the assessment of effectiveness of the Board of Directors appropriately.

【Principle 4-11】

The Board of Directors consists of directors and others with thorough knowledge of each of our business lines, and outside directors who are company managers. While we consider the size of the board appropriate, we cannot say the same with regard to gender and ethnic diversity. As such, we will strive to place importance on diversity when appointing directors going forward. In addition, the Board of Directors, joined by outside directors, shall periodically meet to discuss the structure and management of the board in order to improve its capabilities and effectiveness. Our Board of Auditors comprises three independent auditors, including tax accounts and persons with experience in corporate management, with expert knowledge and experience in management, finance, accounting, sales, auditing, etc.

<Disclosure Based on the Principles of the Corporate Governance Code (Excerpts)>

【Principle 1-4 Strategically held shares】

From the viewpoint of business expansion based on maintaining and strengthening long-term, stable partnerships with business partners, etc., we will acquire and hold the shares of business partners, etc., if we judge that this will contribute to the improvement of our mid/long-term corporate value. For equity investments premised on forming business alliances, the management meets with and receives explanations of the operating environment, business strategy, and purposes of the capital alliance from representatives of the other party. Based on this, the Board of Directors comprehensively evaluates the appropriateness of the stock valuation report and judges whether the deal should take place. For strategically held shares, the Board of Directors constantly checks whether the holding of such shares will contribute to the improvement of our corporate value and confirms the purpose and rationality of said holding based on that check. Our company will appropriately buy/sell shares and exercise voting rights in accordance with relevant regulations, based on a comprehensive evaluation from the viewpoint of improving our corporate value.

【Principle 5-1 Policy on constructive dialogue with shareholders】

Regarding requests from shareholders for dialogue (interviews), our company believes that we should express a positive attitude within a reasonable scope in order to contribute to sustainable growth and medium- and long-term improvement of the corporate value of our company. Aiming to promote constructive dialogue with shareholders, with the planning department designated as a department in charge of IR activities, our company holds financial results briefings targeted at financial institutions and investors semiannually and discloses corporate information as needed on our website and through the system of optional disclosure offered by Tokyo Stock Exchange.

This report is not intended for soliciting or promoting investment activities or offering any advice on investment or the like, but for providing information only. The information included in this report was taken from sources considered reliable by our company. Our company will not guarantee the accuracy, integrity, or appropriateness of information or opinions in this report. Our company will not assume any responsibility for expenses, damages or the like arising out of the use of this report or information obtained from this report. All kinds of rights related to this report belong to Investment Bridge Co., Ltd. The contents, etc. of this report may be revised without notice. Please make an investment decision on your own judgment. Copyright(C) Investment Bridge Co., Ltd. All Rights Reserved. |