Bridge Report:(4634)Toyo Ink SC the second quarter of Fiscal Year ending December 2020

Satoru Takashima President | Toyo Ink SC Holdings, Co., Ltd. (4634) |

|

Company Information

Market | TSE 1st Section |

Industry | Chemical (Manufacturing) |

President | Satoru Takashima |

HQ Address | 2-2-1 Kyobashi, Chuo-ku, Tokyo |

Year-end | End of December |

Homepage |

Stock Information

Share Price | Shares Outstanding | Total market cap | ROE Act. | Trading Unit | |

¥1,858 | 60,621,744 shares | ¥112,635 million | 3.9% | 100 shares | |

DPS Est. | Dividend yield Est. | EPS Est. | PER Est. | BPS Act. | PBR(x) |

¥90.00 | 4.8% | ¥102.72 | 18.1x | ¥3,757.35 | 0.5x |

* Share price as of closing on August 31. Number of shares outstanding, DPS and EPS are taken from the financial statements for the second quarter of FY 12/20.

* ROE and BPS are taken from the financial statements for the previous term.

Earnings Trend

Fiscal Year | Sales | Operating Income | Ordinary Income | Net Income | EPS | DPS |

March 2017 (Act.) | 268,484 | 19,231 | 19,262 | 12,702 | 43.00 | 16.00 |

December 2017 (Act.) | 240,344 | 16,774 | 17,473 | 10,376 | 35.55 | 16.00 |

December 2018 (Act.) | 290,208 | 15,276 | 15,429 | 11,847 | 202.93 | 85.00 |

December 2019 (Act.) | 279,892 | 13,174 | 13,847 | 8,509 | 145.72 | 90.00 |

December 2020 (Est.) | 260,000 | 12,000 | 11,500 | 6,000 | 102.72 | 90.00 |

*Unit: million yen、yen. Estimates are those of the Company. Net income is net income attributable to the shareholders of the parent company.

The values of December 2017 are for 9 months. A 1-for-5 reverse split was conducted on July 1, 2018.No retroactive adjustment has been implemented.

This Bridge Report provides Toyo Ink SC Holdings, Co., Ltd.’s earnings results for the second quarter of Fiscal Year ending December 2020, and more.

Table of Contents

Key Points

1. Company Overview

2. The second quarter of Fiscal Year ending December 2020 Earnings Results

3. Fiscal Year ending December 2020 Earnings Forecasts

4. Conclusions

<Reference1:Mid-Term Business Plan “SIC-I” (FY 2018 to FY 2020)>

<Reference2: Regarding Corporate Governance>

Key Points

- For the second quarter of the term ending Dec. 2020, sales decreased 11.5% year on year to 123.2 billion yen. Global consumption activities were stagnant due to the impact of the novel coronavirus. The demand for offset inks and plastic colorants has declined significantly and sales fell in all segments. Operating income decreased 9.2% year on year to 5.5 billion yen. There were some positive factors such as fixed cost reduction (+2.4 billion yen) including cost reduction due to decrease in sales volume and structural reforms, raw material price reduction (+1 billion yen), and expansion of sales of high value-added products (+500 million yen) such as environmentally friendly products, sensor materials, and functional films. Nonetheless, sales volume decreased (-4.2 billion yen) due to the impact of the novel coronavirus, and sales prices of materials for display fell (-400 million yen).

- Due to the impact of the novel coronavirus, the earnings forecast for the term ending Dec. 2020 has been revised downward. Sales are estimated to decrease 7.1% year on year to 260 billion yen, and operating income is expected to decrease 8.9% to 12 billion yen. The impact of the novel coronavirus crisis is projected to cause a long-term decline in sales volume, a drop in unit sales prices, and changes in the supply chain due to restrictions on the movement of people. Regarding operating income, the decline in demand is estimated to lead to a decrease of 2.2 billion yen in the first half and 4 billion yen for the full year. On the other hand, it will generate 1 billion yen through capturing new demand and structural reforms. Moreover, the company is taking into consideration the possibility of an increase in foreign exchange losses due to the appreciation of the yen and the depreciation of currencies of developing countries, a potential increase in corporate tax adjustments due to sluggish profit growth, and the possibility of losses due to business restructuring. The dividend is to be 90.00 yen/share, unchanged from the previous year. The estimated payout ratio is 87.6%.

- Unfortunately, due to the impact of the novel coronavirus, the full-year forecast has been revised downward. Thus, it is certain that the numerical targets of the medium-term management plan “SIC-I” (FY2018-FY2020) will not be achieved. Analog printing is expected to have a more difficult business environment in the future and there are uncertainties about the investment trends of automobile manufacturers and electronics manufacturers, which are consumers of the company. However, electronics, automobiles, and healthcare are domains where constant or further demand expansion can be expected even after the pandemic. We would like to pay attention to the policies and concrete measures in the next medium-term management plan scheduled for February next year.

1. Company Overview

Toyo Ink SC Holdings is Japan’s top manufacturer of printing inks. Using the processing technologies of pigments and polymers that are the raw materials of inks, the Company manufactures various products such as LCD color filter materials and electromagnetic shielding films. The Toyo Ink Group is comprised of Toyo Ink SC Holdings, 62 consolidated subsidiaries in and outside Japan, and 7 equity method affiliate companies. They are operating business in 23 countries around the world (The end of December 2019).

Under the long-term scheme “Scientific Innovation Chain 2027 (SIC 27),” whose concept is to contribute to the improvement of sustainability of ordinary citizens, life, and the global environment by innovatively thinking, scientifically executing, and connecting each activity by each and every employee, it is aiming for a transformation to have a corporate structure that enables sustainable growth towards 2027

1-1 Corporate History

The origin of Toyo Ink dates back to 1896, when founder Kamataro Kobayashi opened Kobayashi’s Ink Shop as sole proprietorship in Nihonbashi, Tokyo. In 1907, it was reorganized and renamed as Toyo Ink Manufacturing Co., Ltd. During the Meiji period, many newspapers and magazines, including the Yomiuri Shimbun (founded in 1874) and the Asahi Shimbun (founded in 1879), were launched. The government also printed an increasing number of materials including textbooks to enhance educational levels under the policy of increasing wealth and military power. Under these circumstances, the demand for printing inks expanded rapidly.

Initially, inks in the Japanese market were mostly imported products; however, as the national policy favored high quality domestically produced inks, the Company, with its advanced technological skills, successfully expanded its business with clients such as the Printing Bureau of the Ministry of Finance and other government bodies, in addition to private printing companies. Exports also grew during the same time. The Company’s rapid growth was also due in part to the early introduction of integrated manufacturing system from raw materials (pigments, polymers) to finished products (printing inks). Another contributing factor may be that the Company, since its inception, had strong ties with Toppan Printing Co., Ltd., which, by then, was among Japan's largest printing companies. The Company survived the difficult times of the Great Kanto Earthquake and the World War II and experienced rapid growth again during the period of high economic growth after the war. The Company was listed on the Second Section of the Tokyo Stock Exchange in 1961 and moved to the First Section of the Tokyo Stock Exchange in 1967.

The Company is expanding its businesses from manufacturing of printing inks to other fields such as LCD color filters, using its wide range of technologies and know-how cultivated through manufacturing and processing of raw materials such as pigments and polymers. In 2011, the Company adopted a holding company system for further expansion and growth of the Group, and changed its name to Toyo Ink SC Holdings, Co., Ltd.

1-2 Management Philosophy etc.

“The Toyo Ink Group’s Corporate Philosophy System” was established in April 1993. It consists of three parts, namely, corporate philosophy, corporate policies, and guiding principles. The Philosophy embodies the original roots of the brand of the corporate group and serves as guidelines that each employee of the Group should always keep in mind and act on as a business professional. In April 2014, “improving shareholder satisfaction” was added to its guiding principles. With this revision, the Company is aiming to improve satisfaction of all stakeholders.

<Toyo Ink Management Philosophy>

Management philosophy | People-oriented management |

|

|

Corporate policies | We, the Toyo Ink Group, endeavor to be a company that contributes to the enrichment of life and culture throughout the world. *Contribute to the affluence and culture of people worldwide. *Create lifestyle value for the new age. *Provide advanced technology and quality products and services. |

|

|

Guiding principles | *Provide knowledge that enhances customer trust and satisfaction. *Respect the materialization of all employees' dreams. *Act as a responsible citizen in harmony with society and the environment *Respect shareholders' rights, improve shareholder value and enhance market valuation. |

All employees must always carry this philosophy system printed on a credo card, read it out in the 5-minute meeting every week at each division, and repeatedly confirm its meaning through discussion. This way, the employees are expected to have deeper understanding and implement the philosophy.

Furthermore, the “Toyo Ink Group Management Philosophy” is printed on the first page of every single issue of the Company's in-house magazine, which is published for the Group's unity and circulated to the entire Group including the overseas locations. Also, the above-mentioned credo has “Japanese/English” version as well as “Chinese/English” version to share and spread the management philosophy globally.

1-3 Market Environment

◎ Overview

(Market trend)

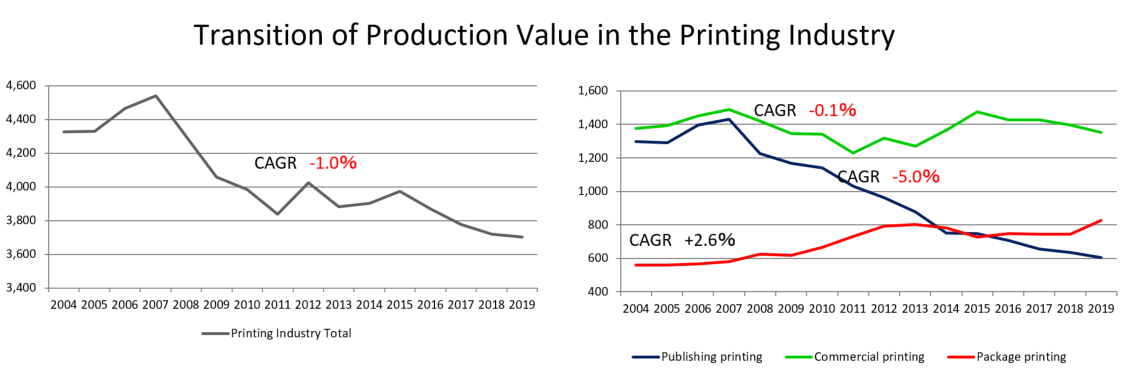

The production value of the Japanese printing industry is declining especially in the realm of publication printing of newspapers and magazines as a result of increasing digitization and aliteracy.

In the realm of commercial printing, on the other hand, of posters, catalogues, fliers, POP, etc. demand is fairly steady. Furthermore, printing on food and pharmaceutical packages and plastic containers is steadily increasing at the compound annual growth rate (CAGR) of 2.6% for 15 years from 2004 to 2019.

Meanwhile, overseas, especially in newly emerging countries, both printing on papers (offset printing) and printing on film of food packages (gravure printing, flexographic printing) are expected to grow, and the Company is focusing on responding to the demand.

As innovation of printing machine is progressing, quality of printing is enhancing. Overseas local inks, in many cases, cannot respond to such demand for high quality, which may lead to more demand of excellent Japanese ink.

Also, with the growing global awareness of the environment, the needs for environmentally friendly products such as biomass inks are expanding, and ink companies are working on the development of new products that utilize their unique technologies.

◎ Other companies in the industry

There are six major listed companies including Toyo Ink in the ink industry in Japan.

While (4631) DIC is the number one company in the world, Toyo Ink is the top runner in Japanese printing ink industry, and ranks first or second in most product categories. Globally, the Company is ranked third (The second is a European firm). (4633) SAKATA INX is the second largest shareholder of the Company. The Company and SAKATA INX complement each other mainly in logistical aspects. The two companies concluded a capital and business alliance agreement in 2000.

Due to the impact of the novel coronavirus, all of them have revised their earnings forecasts downward since the last report.

|

| Sales | Sales growth rate | Operating income | Profit growth rate | Operating margin | Total market value | PER | PBR | ROE |

4116 | Dainichiseika Color & Chemicals Mfg. Co., Ltd. | 126,000 | -18.8% | 500 | -89.7% | 0.4% | 40,129 | 22.2 | 0.4 | 4.1 |

4631 | DIC | 700,000 | -8.9% | 35,000 | -15.3% | 5.0% | 240,080 | 15.9 | 0.8 | 7.7 |

4633 | SAKATA INX | 161,800 | -3.3% | 7,000 | +12.4% | 4.3% | 61,161 | 13.6 | 0.8 | 5.5 |

4634 | Toyo Ink SCHLD | 260,000 | -7.1% | 12,000 | -8.9% | 4.6% | 112,635 | 18.1 | 0.5 | 3.9 |

4635 | Tokyo Printing Ink Mfg. Co., Ltd. | 40,000 | -6.0% | 340 | -42.6% | 0.9% | 5,527 | - | 0.2 | 5.1 |

4636 | T&K TOKA | 41,030 | -14.9% | 0 | -100.0% | 0.0% | 19,242 | 88.4 | 0.4 | 1.4 |

*Sales and operating income are based on forecasts of each company for this FY. ROE and PBR are based on actual results of the previous term end.

*Unit: Million Yen, Times. Total market value is as of closing on August 31, 2020.

1-4 Business Description

◎ Concerning “printing inks”

Followings are the summary of printing inks, one of the major product categories of the Company, categorized by “raw materials” and “types and purposes of use.”

<Composing elements of printing inks>

Pigments (organic pigments, inorganic pigments, etc.) | Pigments are powders that are used to provide color and are insolvent to water and oil. |

Varnish (synthetic polymers, lipids, fluxing materials, etc.) | Varnish is a combination of lipids, natural polymers, synthetic polymers, etc. in a solvent. It diffuses pigments, transfers and fixes them to printing materials. |

Additives (lubricant, hardening agent, etc.) | Additives used to adjust so-called printability such as drying performance and fluidity, as well as printing effect. |

High-level dispersion technologies are required when various inks are produced by combining the above three raw materials.

Since its foundation, the Company has also been expanding its business categories by exploring application of these raw materials in the process of manufacturing them.

<Types and intended use of major printing inks>

Types | Characteristics and Intended Use |

Planographic inks | Typical printing ink on paper. They are used for printing magazines, posters, fliers, etc. |

Gravure inks | Because of their capacity to express detailed gradation, it is suitable for printing photo images. Currently, they are mainly used for printing films such as food wrapping materials. |

Screen inks | They are mainly used for printing on materials that are difficult to be printed with other methods, including industrial products such as meters and gauges of cars, circuit board formation, and CDs/DVDs. |

Flexographic inks | They are used to print on the surface of cardboard boxes, films and clothes. |

UV curing inks | Because they dry instantly without using a heat drier in the drying process, they are used for UV curing printing that does not directly generate CO2. They are environmentally friendly inks that do not generate Volatile Organic Compounds (VOC). |

◎Business segments

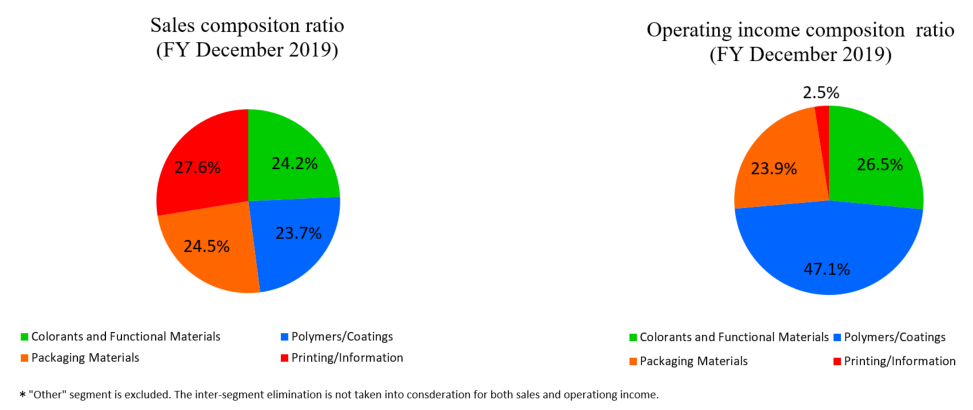

The business activities of the Company are classified into four segments: the “Colorants & Functional Materials Related Business,” “Polymers & Coatings Related Business,” “Printing & Information Related Business”, and “Packaging Materials Related Business”.

The “Printing & Information Related Business” mainly deals with planographic inks that are used for printing on papers (offset inks, etc.). The “Packaging Materials Related Business” deals with gravure inks and flexographic inks that are used for printing on films of food packages. The “Colorants & Functional Materials Related Business” deals with products related to pigments that are also the raw materials of printing inks as core materials. The “Polymers & Coatings Related Business” began with polymers that are the main raw materials of inks and their design technologies.

☆Colorants and Functional Materials Related Business

| FY Dec.19 |

Sales | 67,400 |

Operating Income | 3,386 |

Operating Margin | 5.0% |

*Units: Million yen

Sub segment | Major products |

General-purpose chemicals | Pigments and pigment dispersions |

High-performance chemical products | High function pigments, CF(color filter) paste |

Display materials | Resist inks for LCD color filter |

Plastic colorants | Plastic colorants, functional colorants |

Other Colorants/Functional Materials | Recording material coatings, functional dispersions, developed products |

|

|

Based on the organic pigments that are the main raw materials for printing inks, and by integrating their color material technologies, organic chemical synthetic technologies and high-level dispersion technologies, the Company offers materials that are used in various fields. Especially, it created higher functional LCD color filter materials using their nano-level dispersion technologies through integration of technologies that have been accumulated from their ink and painting materials production experiences. Furthermore, the Company’s dispersion processing technologies are used not only for organic pigments but also for inorganic materials such as carbon nanotube (CNT), which leads to expansion of its business in the new energy field such as secondary battery materials.

☆Polymers & Coatings Related Business

| FY Dec.19 |

Sales | 65,887 |

Operating Income | 6,013 |

Operating Margin | 9.1% |

*Units: Million yen

Sub segment | Major products |

Functional films and tapes | Adhesive tapes, marking films, electromagnetic shielding films |

Adhesives | Pressure sensitive adhesives, Adhesives, laminating adhesives, hot-melts |

Can coatings and polymers | Can coatings, polymers, functional hard coatings |

Other Polymers/Coatings | Medical products, natural extracts, developed products |

|

|

For this segment, the Company develops functional polymers as the core materials with different functional features. Using unique technologies that have been developed for many years, the Company creates new functions to cultivate new demand and open new markets in electronics, energy, health care and other fields.

☆Packaging Materials Related Business

| FY Dec.19 |

Sales | 68,071 |

Operating Income | 3,058 |

Operating Margin | 4.5% |

*Units: Million yen

Sub segment | Major products |

Liquid inks | Gravure inks, flexographic inks, gravure solvent |

Gravure equipment, plate making | Gravure equipment/plate making, gravure and flexographic platemaking |

|

|

For this segment, the Company deals with printing inks and equipment used in packages such as gravure printing and flexographic graphic printing. In the field of food packaging materials, etc., the Company is dedicated to developing environmentally friendly products using water-based ink to assure their safety to the consumers.

☆Printing & Information Related Business

| FY Dec.19 |

Sales | 76,680 |

Operating Income | 314 |

Operating Margin | 0.4% |

*Units: Million yen

Sub segment | Major products |

Offset inks | Offset inks, newspaper inks, UV curable inks, metal decorating inks |

Printing materials and equipment | Printing inspection devices, printing materials |

Inkjet inks, others | Inkjet inks, screen inks, other developed products |

|

|

This segment is the core segment of the Company since its establishment. For this segment, the Company deals mainly with printing inks used for printing on paper.

The Company offers not only printing inks but also sales of machinery/equipment, support for streamlining customers’ printing process, and support and tools for color management and color universal design.

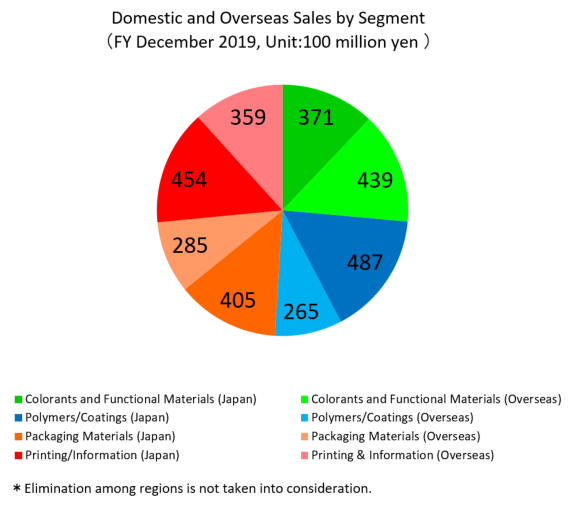

◎Overseas expansion

While the Company is improving profitability by offering high-value-added products in the Japanese market, where a rapid growth is not expected, it is aggressively expanding its business from both production and sales perspectives in the overseas market where future growth is expected.

Development of its overseas manufacturing structures was almost completed during the previous Midterm Business Plan, and the Company is carrying out both raw material procurement and production at local sites.

As of the end of December 2019, the Company has about 44 overseas consolidated subsidiaries in a wide range of countries around the world.

| Sales | YoY | Operating Income | YoY |

Japan | 1,755 | -3.4% | 78 | -19.0% |

Asia | 1,012 | -5.0% | 57 | +4.1% |

Europe | 198 | -1.8% | -2 | - |

The Americas | 140 | -1.9% | -2 | - |

Adjustment | -306 | - | 1 | - |

Consolidated total | 2,798 | -3.6% | 131 | -13.8% |

*Units: Million yen

<Segment trend by region: FY December 2019>

1-5 ROE Analysis

| FY 3/ 13 | FY 3/ 14 | FY 3/ 15 | FY 3/ 16 | FY 3/ 17 | FY 12/ 17 | FY 12/ 18 | FY 12/ 19 |

ROE (%) | 5.8 | 7.3 | 6.9 | 5.8 | 6.1 | 4.8 | 5.4 | 3.9 |

Net income margin (%) | 3.50 | 4.39 | 4.64 | 4.17 | 4.73 | 4.32 | 4.08 | 3.04 |

Total asset turnover [times] | 0.85 | 0.88 | 0.82 | 0.78 | 0.74 | 0.65 | 0.77 | 0.75 |

Leverage [times](x) | 1.94 | 1.88 | 1.81 | 1.75 | 1.74 | 1.72 | 1.72 | 1.72 |

*The 12-months conversion value for the term ended December 2017 is 6.8%.

In general, it is desirable to continue to boost profitability and efficiency to achieve a ROE of 8%, which is said to be the value that should be pursued by Japanese companies.

1-6 Characteristics and Strengths

(1) Strong technological edge

As described above, the Company has been manufacturing in-house pigments and polymers, which are the raw materials of printing inks. Its technological capacities form the basis of high-quality printing ink production and lead to expansion of business areas and product range such as, LCD color filter materials, adhesive bonds and adhesive compounds.

(2) Excellent problem-solving skills

One of the reasons for the Company to be at the top of the Japanese printing inks industry is its excellent problem-solving capability in all aspects of printing.

The Company not only produces and supplies printing inks but also studies elements related to “printing” as a whole including plate making and images. Such efforts enable the Company to make technological proposals, demonstrate advanced service skills, and obtain high customer satisfaction.

(3) Environmental concerns

The Company is a forerunner in CO2 emission reduction as well as production of eco-friendly inks such as non-VOC inks, water-based inks, and UV inks. In the newly developed countries, too, the environmental regulations are becoming tighter, and the needs for environmentally friendly products are increasing. The Company is also working on assuring safety such as chemical substances control and manufacturing a line of products that meet the Swiss Ordinance, ahead of other companies.

(4) Uniqueness of management strategies

The Company considers M&A as one of the options for exploring new markets with its technological edge, if M&A is expected to bring synergy effects to the Company. However, it is not intending to implement M&A just to increase the size of businesses. It is also taking an initiative in the printing ink industry to establish “local production for local consumption” policy in the overseas market for enhancing efficiency (e.g. reduction in transport mileage) and social contribution (e.g. utilization of local products) purposes.

2. The second quarter of Fiscal Year ending December 2020 Earnings Results

(1) Business Results

| FY 12/ 19 2Q | Ratio to sales | FY 12/ 20 2Q | Ratio to sales | YoY |

Sales | 139,376 | 100.0% | 123,290 | 100.0% | -11.5% |

Gross profit | 30,313 | 21.7% | 27,388 | 22.2% | -9.6% |

SG&A | 24,202 | 17.4% | 21,838 | 17.7% | -9.8% |

Operating Income | 6,111 | 4.4% | 5,549 | 4.5% | -9.2% |

Ordinary Income | 6,347 | 4.6% | 4,933 | 4.0% | -22.3% |

Quarterly Net Income | 2,770 | 2.0% | 2,646 | 2.1% | -4.5% |

*Units: Million yen

Sales and Profit decreased

Sales decreased 11.5% year on year to 123.2 billion yen. Global consumption activities were stagnant due to the impact of the novel coronavirus. The demand for offset inks and plastic colorants has declined significantly and sales fell in all segments. Operating income decreased 9.2% year on year to 5.5 billion yen. There were some positive factors such as fixed cost reduction (+2.4 billion yen) including cost reduction due to decrease in sales volume and structural reforms, raw material price reduction (+1 billion yen), and expansion of sales of high value-added products (+500 million yen) such as environmentally friendly products, sensor materials, and functional films. Nonetheless, sales volume decreased (-4.2 billion yen) due to the impact of the novel coronavirus, and sales prices of materials for display fell (-400 million yen).

(2) Trend by Segment

Sales | FY 12/ 19 2Q | Ratio to sales | FY 12/ 20 2Q | Ratio to sales | YoY |

Colorant/Functional materials | 34,620 | 24.8% | 28,757 | 23.3% | -16.9% |

Polymers/Coatings | 32,701 | 23.5% | 29,931 | 24.3% | -8.5% |

Packaging materials | 33,434 | 24.0% | 32,910 | 26.7% | -1.6% |

Printing/Information | 37,633 | 27.0% | 30,813 | 25.0% | -18.1% |

Others | 3,652 | 2.6% | 3,319 | 2.7% | -9.1% |

Adjustment | -2,667 | - | -2,442 | - | - |

Total | 139,376 | 100.0% | 123,290 | 100.0% | -11.5% |

Operating Income |

|

|

|

|

|

Colorant/Functional materials | 1,949 | 5.6% | 1,291 | 4.5% | -33.8% |

Polymers/Coatings | 2,789 | 8.5% | 2,449 | 8.2% | -12.2% |

Packaging materials | 1,148 | 3.4% | 1,916 | 5.8% | +66.9% |

Printing/Information | 37 | 0.1% | -246 | - | - |

Others | 193 | 5.3% | 143 | 4.3% | -25.9% |

Adjustment | -8 | - | -4 | - | - |

Total | 6,111 | 4.4% | 5,549 | 4.5% | -9.2% |

*Unit: million yen. Ratio to sales for operating income means the profit margin.

☆Colorants and Functional Materials Related Business

Sales and profit decreased.

The sales of materials for display, which are the company’s priority products, decreased 11%.

(Pigments)

Although sales expanded in Japan and overseas, it was affected by the shrinking printing market and the decline in demand due to the novel coronavirus crisis. New projects have been achieved in the inkjet ink market.

(Materials for display)

In Japan, the demand for applications in automobiles and industrial machineries decreased due to the novel coronavirus crisis, and the demand for televisions was sluggish due to operational adjustments.

Overseas, unit prices continued to decline in the Chinese market, but factory utilization rate remained high.

(Plastic colorants)

Inbound demands, and going-out and leisure demands fell sharply. The operation of users in the automobile and building materials industry was stagnant.

On the other hand, sales of sterilization and antibacterial containers, and food packaging materials were strong.

(Functional dispersions)

Production plans for automotive lithium-ion battery materials have progressed at overseas bases.

☆Polymers & Coatings Related Business

Sales and profit decreased.

The sales of optical electronics products and medical/healthcare-related products, which are the company’s priority products, decreased by 9.5% and 10.3%, respectively.

(Functional films and tapes)

The sales of high-frequency shields for 5G grew but were generally affected by the decline in the smartphone market. The sales for tablets increased due to remote usage demands, but the sales for television display products were sluggish.

(Adhesives)

In Japan, the sales for packaging and labels were strong, but the sales for polarizing plates and lithium-ion batteries were sluggish.

Overseas, sales were greatly affected by the suspension of operations at the group’s production bases and business partners due to the coronavirus crisis.

(Can coatings and polymers)

The sales of can coatings for alcohol cans increased, but overall sales decreased from the previous year due to a decrease in demand for outings and leisure activities.

The sales of polymers for construction and civil engineering purposes decreased due to the suspension of general contractor construction work due to the novel coronavirus crisis.

☆Packaging Materials Related Business

Sales decreased and profit increased.

The performance of overseas liquid inks, which are the company’s priority products, is nearly unchanged from the previous year.

(Flexible packaging materials)

In Japan, the sales of flexible food packaging materials were strong due to “demand from people staying at home,” but the sales of beverage labels, etc. were sluggish due to the restrictions on going out.

Overseas, the demand for ink for flexible food packaging materials was strong as the operation restrictions were lifted early for essential businesses.

(Building materials)

Demand declined due to the stagnation and delays in the construction and remodeling markets caused by the novel coronavirus crisis.

(Cardboard)

Demand in the paper bag field (crafts) vanished due to the closure of department stores and specialty stores, and the decrease in inbound demand. Cardboard was also in demand for mail orders, but it was limited. There was a partial progress in price revisions.

☆Printing & Information Related Business

Sales and profits decreased.

The sales of functional inks, which are the company’s priority products, decreased by 14.6%.

(Offset inks)

In Japan, the sales of commercial printing such as leaflets and newspaper ink were sluggish due to the restrictions on going out.

Overseas, the commercial printing market was sluggish in the second quarter due to the impact of the novel coronavirus crisis, mainly in the Western markets.

(Functional inks)

For inkjet, the development of water-based inks for flexible packaging has progressed.

The cost of UV inks has been reduced, but it has not made up for the slump in the commercial printing market.

Production of metal decorating inks has started in Thailand and South Korea.

(3) Financial standing and cash flows

◎Main Balance Sheet

| End of December 2019 | End of June 2020 |

| End of December 2019 | End of June 2020 |

Current Assets | 199,969 | 202,550 | Current liabilities | 106,747 | 100,383 |

Cash | 56,691 | 67,305 | Payables | 59,543 | 47,997 |

Receivables | 90,173 | 80,766 | ST Interest Bearing Liabilities | 30,315 | 33,671 |

Inventories | 48,508 | 50,706 | Noncurrent liabilities | 42,490 | 50,938 |

Noncurrent Assets | 176,161 | 165,091 | LT Interest Bearing Liabilities | 27,460 | 39,612 |

Tangible Assets | 99,577 | 99,604 | Total Liabilities | 149,237 | 151,322 |

Intangible Assets | 4,202 | 3,629 | Net Assets | 226,892 | 216,318 |

Investment, Others | 72,381 | 61,857 | Shareholders’ Equity | 205,891 | 205,935 |

Total assets | 376,130 | 367,641 | Total liabilities and net assets | 376,130 | 367,641 |

|

|

| Capital Adequacy Ratio | 58.3% | 56.8% |

*Unit: million yen

Current assets increased 2.5 billion yen from the end of the previous fiscal year due to a rise in cash and deposits. However, total assets decreased 8.4 billion yen from the end of the previous fiscal year to 367.6 billion yen due to a decline in investment and other assets.

Total liabilities augmented 2 billion yen from the end of the previous fiscal year to 151.3 billion yen due to an increase in long-term debt. Net assets dropped 10.5 billion yen from the end of the previous fiscal year to 216.3 billion yen due to a decline in valuation difference on available-for-sale securities.

As a result, equity ratio fell 1.5 points from 58.3% at the end of the previous fiscal year to 56.8%.

◎Cash Flow

| FY 12/19 2Q | FY 12/20 2Q | Increase/decrease |

Operating Cash Flow | 10,094 | 4,612 | -5,482 |

Investing Cash Flow | -4,848 | -5,567 | -719 |

Free Cash Flow | 5,246 | -955 | -6,201 |

Financing Cash Flow | -4,585 | 12,829 | +17,414 |

Term End Cash and Equivalents | 51,149 | 65,023 | +13,874 |

*Unit: million yen

Free cash flow turned negative due to a decrease in trade payables, and financing cash flow turned positive due to an increase in long- term and short-term debts.

The cash position has risen.

3. Fiscal Year ending December 2020 Earnings Forecasts

(1) Business forecasts

| FY 12/ 19 | Ratio to sales | FY 12/ 20 Est. | Ratio to sales | YoY | Revision rate |

Sales | 279,892 | 100.0% | 260,000 | 100.0% | -7.1% | -10.3% |

Operating Income | 13,174 | 4.7% | 12,000 | 4.6% | -8.9% | -20.0% |

Ordinary Income | 13,847 | 4.9% | 11,500 | 4.4% | -17.0% | -25.8% |

Net Income | 8,509 | 3.0% | 6,000 | 2.3% | -29.5% | -40.0% |

*Unit: Million yen. Forecasts are the figures announced by the Company.

The forecast revised downward due to the impact of the novel coronavirus. Sales and profits are estimated to decrease.

Due to the impact of the novel coronavirus, the earnings forecast for the term ending Dec. 2020 has been revised downward. Sales are estimated to decrease 7.1% year on year to 260 billion yen, and operating income is expected to decrease 8.9% to 12 billion yen. The impact of the novel coronavirus crisis is projected to cause a long-term decline in sales volume, a drop in unit sales prices, and changes in the supply chain due to restrictions on the movement of people. Regarding operating income, the decline in demand is estimated to lead to a decrease of 2.2 billion yen in the first half and 4 billion yen for the full year. On the other hand, it will generate 1 billion yen through capturing new demand and structural reforms. Moreover, the company is taking into consideration the possibility of an increase in foreign exchange losses due to the appreciation of the yen and the depreciation of currencies of developing countries, a potential increase in corporate tax adjustments due to sluggish profit growth, and the possibility of losses due to business restructuring. The dividend is to be 90.00 yen/share, unchanged from the previous year. The estimated payout ratio is 87.6%.

(2) Trends by Segment

Sales | FY 12/ 19 | FY 12/ 20 Est. | YoY | Revision rate |

Colorant/Functional materials | 674 | 610 | -9.5% | -15.9% |

Polymers/Coatings | 659 | 645 | -2.1% | -8.5% |

Packaging materials | 681 | 685 | +0.6% | -2.1% |

Printing/Information | 767 | 640 | -16.6% | -15.8% |

Others/Adjustment | 19 | 20 | +5.3% | +100.0% |

Total | 2,798 | 2,600 | -7.1% | -10.3% |

Operating Income |

|

|

|

|

Colorant/Functional materials | 34 | 26 | -23.5% | -31.6% |

Polymers/Coatings | 60 | 57 | -5.0% | -12.3% |

Packaging materials | 31 | 40 | +29.0% | +14.3% |

Printing/Information | 3 | 0 | -100.0% | -100.0% |

Others/Adjustment | 4 | -3 | -175.0% | 0.0% |

Total | 131 | 120 | -8.9% | -20.0% |

* Unit: 100 million yen.

(Key issues and important measures in each segment in the second half)

☆Colorant/Functional materials

(Pigments)

To expand sales of existing products, achieve results for newly developed products, and reduce costs

Development of digital printing materials and global sales expansion

(Materials for display)

Further improvement of the company’s presence in the Chinese market

Promoting the development of sensor materials as a next-generation business

(Plastic Colorants)

Strengthening supply to meet sterilization and antibacterial related demands and food packaging material related demands

Development of environmentally friendly products and achievement of results for functional master batches.

(Functional dispersion)

To expand sales of automotive lithium-ion battery materials to the European and American EV markets

Development of functional dispersions related to electronics, mobility, and pharmaceuticals

Important measures

The company will promote the development of new materials using optical control technology.

In the medical field, the company will develop pharmaceutical packaging materials that use UV control, and contribute to extending the warranty period of pharmaceuticals and reduce the burden on medical professionals.

In the field of mobility, the company will develop sensors that use near-infrared control technology and provide security functions such as collision avoidance.

☆Polymers/Coatings

(Packaging and industrial materials)

Global expansion of environmentally friendly products centered on approaching brand owners

Expansion of high value-added products such as polymers for lithium-ion battery separators

(Electronics)

Expansion into the 5G and IoT market (high-speed communication terminals and base stations)

To meet the demand for devices for remote usage (tablets, etc.)

(Medical and healthcare)

Expansion of new pipelines of adhesive patches

Expansion of adhesives to the U.S. and Chinese healthcare markets

Expansion of antibacterial and antiviral products

Important measures

As for pressure sensitive adhesives, the company will promote the expansion of environmentally friendly product lines (water-based/solvent-free, high solids, biomass, etc.) that achieve reduction of solvent emissions, carbon neutrality, and environmental isolation that brings safety and security.

Because of the rapid spread of telecommuting, remote learning, and remote medical care due to the novel coronavirus crisis, the needs for ultra-high speed, super-low latency, and multiple simultaneous connections are expanding.

In response to this trend, the company will focus on expanding sales of product lines for devices for remote usage, developing shielding materials for high-speed terminals and low-dielectric parts, and developing substrates for base stations and semiconductor-related parts.

☆Packaging materials

(Packaging and building materials)

Japan: Development and sales expansion of environmentally friendly products, efficiency improvement of production, promotion of development in the field of building materials, and expansion of the market share of flexographic inks by developing new products

Overseas: To meet more demands in areas that have recovered early

Expansion of production facilities in emerging areas

Improving profitability at global bases

(Cardboard)

Penetration of price revisions

Promotion of sales expansion in the craft field

Improving profitability through various cost reduction measures

Important measures

In Japan, the company will work on the development of new environmentally friendly products such as biomass inks and flexographic inks for flexible packaging.

In addition, the company will promote efficiency improvement through product integration and cost reduction to strengthen the business structure.

Overseas, in addition to accelerating the development of non-toluene inks for emerging markets, the company will work on the development of water-based inks targeting China and East Asia in response to VOC reduction needs.

☆Printing/Information

(Offset inks)

To promote structural reforms both in Japan and overseas

To improve profitability by reducing costs such as reviewing raw materials

To accelerate global SCM rebuilding

(Functional inks)

UV inks: Expanding environmentally friendly products to the paper container and packaging markets

Inkjet inks: To accelerate development of products for China and products for flexible packaging

Metal decorating inks: To expand UV curable inks to the Asian market

Important measures

At the beginning of the term, the domestic market was expected to shrink at an annual rate of 5-7% due to DX, but the forecast was revised to accelerate to an annual rate of 20-30% due to the impact of the novel coronavirus crisis. Under such a severe business environment, the company will promote business structural reforms.

The first reassignment of personnel (71 people) was completed in order to downsize the organization. It will decrease 8.9% from 2019.

The company will also promote production optimization through production alliances.

On the other hand, the company will develop the market for other uses in the functional product line.

In addition to developing the EB offset ink product line for the small lot flexible packaging market, the company will strengthen the inkjet product line for flexible packaging.

(3) Impact of the novel coronavirus and future policies

① Impact of the novel coronavirus

For the time being (during the novel coronavirus pandemic), many of the industries targeted by the company (displays, electronics, automobiles, packaging and food, etc.) will be affected due to the sluggish consumption and declining demand. However, after the pandemic settles down, sales are expected to start recovering.

In the healthcare industry, demand is increasing even during the pandemic against the backdrop of an aging population and heightened health awareness.

On the other hand, the shrinking of the analog printing market is estimated to accelerate even after the novel coronavirus subsides. Thus, the company believes that the colorant/functional materials and the printing/information segments will be significantly affected.

② Policies during and after the novel coronavirus pandemic

◎During the novel coronavirus pandemic

To promote new product development to meet new social needs.

Specifically, in order to meet the growing needs for antibacterial and antiviral products, the company will use master batches for food packaging materials in the colorant/functional materials segment, hard coats for face shields in the polymers/coating segment, and UV curable varnish in packaging and printing/information segment.

◎After the novel coronavirus pandemic

As "an enterprise that can create lifestyles and cultures," it will provide products and services to meet the needs of “new normal.”

Specific focus areas and business policies will be announced in the next medium-term management plan.

③ Investment policy

The investment plan for this term was 18.5 billion yen, but it was revised to 17.7 billion yen through flexibly reviewing and postponing some plans in line with the demand fluctuation forecast due to the novel coronavirus.

However, the company will continue to promote investments in key areas and new businesses with a view to the after pandemic phase.

The progress of the main plans for this term is as follows.

Packaging Materials | Turkey | To start the construction of the new factory and to expand the production facilities for gravure ink and laminating adhesives |

Polymers/Coating | USA and China | Expansion and new construction of solvent-based and water-based adhesive production facilities |

Colorant/Functional materials | USA and China | Establishing new production facilities for materials for automotive lithium-ion batteries |

Printing/Information | France | Expansion of production facilities for inkjet inks |

4. Conclusions

Unfortunately, due to the impact of the novel coronavirus, the full-year forecast has been revised downward. Thus, it is certain that the numerical targets of the medium-term management plan “SIC-I” (FY2018-FY2020) will not be achieved. Analog printing is expected to have a more difficult business environment in the future and there are uncertainties about the investment trends of automobile manufacturers and electronics manufacturers, which are consumers of the company. However, electronics, automobiles, and healthcare are domains where constant or further demand expansion can be expected even after the pandemic. We would like to pay attention to the policies and concrete measures in the next medium-term management plan scheduled for February next year.

<Reference1:Mid-Term Business Plan “SIC-I” (FY 2018 to FY 2020) >

Under the long-term 10-year vision “Scientific Innovation Chain 2027 (SIC 27)” to realize sustainable growth for 2027, the company will develop a three-stage medium-term management plan every 3 years, clarify the challenges and roles, and act steadily for the future. It launched the first stage “Medium-Term Management Plan SIC-I (FY2018 - 2020)” January 2018.

<Basic policies>

The theme is “Frequent challenges”

By positioning the next medium-term management plan SIC-I (FY2018 - FY2020) as a period for building a

foundation for sustainable growth in the next 100-year range, we will take successive measures for

innovative change.

(1) Transformation of existing businesses and development of new businesses for growth

(2) Promotion of manufacturing innovation to increase sustainability

(3) Overhaul of management foundation

(Major challenges by segment)

Colorant/Functional materials | ◆Development and expanded sales of products using unique pigments and nano-level dispersion technologies. *LiB-related materials: To try to expand LiB-related materials including carbon dispersion materials, benefiting from accelerating growth of the EV market. *Functional products: To develop products with optical and insulation functions that are new to the market, using its unique materials and nano-level dispersion technologies.

◆Further expansion of color filter material and sensor materials. *To make sure to capture demand for the expanding Chinese market and advance sales of color filter materials for panels. *To strengthen development for the arrival of trillion sensor era. |

Polymers/Coatings | ◆Creation of new markets by solution-proposing marketing based on manufacturing *Electronics: To utilize open innovation and accelerate the development of new materials centered on control of heat and electromagnetic waves. *Packaging and industrial materials: To develop safe and secure materials that contribute to environment and energy-saving.

◆ Medical Science Business to be the next growth pillar. *To strengthen development of adhesive patches. *To increase sales of healthcare-related products such as cell culture coating agents and adhesives used for medical tapes. |

Packaging materials | ◆Acceleration of product development in response to the changes of the market *To promote improvement of the evaluation technology environment from the customer’s point of view and develop stand-by type new products *Inkjet inks: To accelerate product development in accordance with expansion of the market. *Metal decorating inks: To accelerate overseas market expansion.

◆Strengthening environmentally friendly products *Biomass inks: To increase lineups of biomass ink products lineups. *Water-based inks: To accelerate global business expansion by increasing functionality of packaging products. *UV inks: To promote global business expansion in the packaging field.

◆ Construction of a production system to meet regional needs. *To strengthen the supply base and improve CS through the restructuring of the global production systems *To improve CS by strengthening the overseas technology center and technology services. *To strengthen the business foundation by promoting drastic structural reform in the domestic maturity businesses |

Printing/Information |

*From the term ending Dec. 2018, the segment of Functional films and tapes is partially moved from the Printing & Information Related Business to Polymers & Coatings Related Business.

<Major measures>

(1) Transformation of Existing Businesses and Development of New Businesses for Growth

【1-1 Transformation of Existing Businesses】

■ Global development

To raise the growth capacity in overseas markets, it will promote the integration of global bases that have been established so far and the expansion of product lineups and will develop diverse businesses.

For pigment dispersions for inkjet inks and inks, in addition to manufacturing environmentally friendly products in China (Zhuhai), it will increase items in Japan, the US and France.

For laminating adhesives, it will try to increase sales in the food packaging material market in cooperation with global bases that operate liquid ink business.

The company aims for increased sales of 53 billion yen compared with the term ended Dec. 2017.

■ Expansion of new products

The company will promote the development of new materials with a focus on pigments and polymers and create new values by combining synthesis, dispersion and film formation technologies, which are its core technologies, to enter new markets and new areas.

Particularly, it will focus on electronics-related materials and medical/healthcare products in the Polymers & Coatings Related Business.

It aims for increased sales of 16 billion yen compared with the term ended Dec. 2017.

【1-2 Development of New Businesses】

The company set 6 priority domains in the SIC-I. To achieve sustainable growth, it will challenge the development of new business models centered on solution proposals that go beyond merely providing products and will link them to the activities in the “SIC-II” and “SIC-III” phases.

Field | Domain |

Life | Packaging Mobility Medical/healthcare |

Communication | IoT |

Sustainability | Natural extract Energy |

It will focus on the following 4 businesses.

[Sensor-related business]

The domains are mobility, medical/healthcare and IoT.

The company will focus on rapidly increasing “sensors” in the fast growing IoT market. In addition to “manufacturing” centered on chemicals, it will also try to develop sensor-related businesses that incorporate new technologies and provide “information and systems.”

(Major products/services)

The major products/services are image sensor materials and sensor devices. In the “SIC –II” and “SIC –III” phases, development of data business based on sensing data will also be considered.

[Waste-heat from living related business]

The domains are mobility, IoT and energy.

Focusing on “waste-heat from living” which is unused in the surroundings of the living, the company will develop technologies to efficiently recycle the heat and work on a business that provides recycling energy solutions.

(Major products/services)

Heat resistant adhesive film, super heat resistant insulation/heat conductive film, high heat management parts, etc.

[Healthcare related business]

The domain is medical/healthcare.

Based on the adhesive patch business platform, the company will steadily expand its pharmaceutical business base and strengthen development and sales of peripheral healthcare-related materials.

(Major products/services)

Tapes for blood glucose test strips, medical adhesives, biocompatible polymers, next-generation adhesive patches, etc.

[Natural extracts related business]

The domain is natural extracts.

The company aims to further develop businesses of new functional natural extracts making full use of edible pigments and bamboo-related products business platforms and advance the expansion of biomass products to further contribute to the low-carbon society.

(Major products/services)

Edible pigment products, Kuma bamboo grass related products, biomass inks, functional food materials, etc.

(2) Promotion of Manufacturing Innovation to Increase Sustainability

Until now, the company has been working on building a manufacturing network by proactively expanding overseas bases, building safe and secure manufacturing with consideration for the environment, and developing a global chemical substance management and trade management systems.

During the SIC-I phase, to contribute to the improvement of sustainability of ordinary citizens, life, and the global environment, it will tackle innovation in manufacturing for sustainable growth including the company itself and aim to achieve both contributing to sustainability and securing profitability.

(Example of actions)

*Building the global supply chain based on co-existence and co-prosperity with our partners

*Production process innovation integrated with digital technologies

*Promotion of manufacturing to live with the global environment (energy savings, reduction of CO2 emissions, etc.)

(3) Overhaul of Management Foundation

It will drive forward global integration of business systems to reform existing business, create new businesses and reform manufacturing. It will also work on strengthening the management foundation including recruitment of personnel for reform and institutional reform (i.e. complete transition to defined contribution pension system, commencement of retirement age of 65). In addition, it will implement CSR activities integrated with management and contribute to the improvement of the sustainability of ordinary citizens, life and the global environment.

It will strengthen the foundation to continuously create innovations.

(Example of actions)

*Promotion of ERP integration globally and promotion of greater business efficiency using AI

*Active recruitment of human resources necessary for innovative changes and the renovation of the personnel system to encourage innovations

*Promotion of active CSR activities to achieve important issues (materiality) of TIG

<Reference2: Regarding Corporate Governance>

◎ Organization type, and the composition of directors and auditors

Organization type | Company with auditors |

Directors | 11 directors, including 4 external ones |

Auditors | 5 auditors, including 3 external ones |

◎ Corporate Governance Report

The latest update: April 3, 2020.

<Basic policy>

Our corporate group shifted to the holding company structure on April 1, 2011. Under the holding company structure, our company aims to improve the value of the entire corporate group by strengthening its strategic function, promoting speedy business administration, and achieve a good balance between the optimization of the entire group and the optimization of each business.

Our group’s framework for business administration is constituted by the “ethos of the Toyo Ink Group,” which is composed of management philosophy and ethos, which summarize the basic policies for group management, and the course of action, and the “CSR value system,” which is composed of the CSR charter and course of action, which clearly describe the stance toward social responsibility.

Our group aims to contribute to the improvement of sustainability of residents, life, and the earth environment and become “an enterprise that can create lifestyles and cultures that would spread around the world” as set in the management ethos, through science-based manufacturing, by putting the “ethos of the Toyo Ink Group” and the “CSR value system” into practice.

In order to create tangible and intangible values as an enterprise and fulfill social responsibility, it is indispensable to self-evaluate corporate activities from the viewpoint of stakeholders and carry out well-balanced business administration for economic, social, personnel, and environmental affairs.

To do so, our company will:

*transfer the business execution function to each business company, and appropriately enforce the regulations for internal memos and affiliate management, which are adapted to each group company, in order to fortify corporate governance, develop its internal control system,

*improve the instruction and monitoring functions by enhancing the legal functions and systems, such as general meetings of shareholders, the board of directors, the board of auditors, comptrollers, etc.,

*improve the transparency of business administration by disclosing information swiftly, accurately, and broadly,

*strengthen and enrich its compliance system,

*promote environmental conservation on a global scale, and so on,

and foster good relationships with stakeholders, including shareholders, business partners, local communities, and employees, and enhance corporate governance.

<Reasons for Non-compliance with the Principles of the Corporate Governance Code>

Our company implements all the principles of the corporate governance code.

<Disclosure Based on the Principles of the Corporate Governance Code (Excerpts)>

Principle | Disclosure contents |

Principle 1-4. | The economic rationality of strategically held shares is discussed annually at the board of directors’ meeting. The company will examine the benefits and transaction status associated with the cross-holding as compared to the cost of capital for each individual stock, and if the cross-holding of the stock is determined not to be appropriate, the company will proceed with reduction based on the status of the issuing company and market trends. In the previous fiscal year, all strategically held shares of four companies and part of strategically held shares of two companies were sold. The voting rights of strategically held shares are exercised appropriately for each bill, after considering qualitatively and comprehensively whether the bill would contribute to the mid/long-term improvement in the value of the share issuing company, whether the bill would contribute to the common interests of shareholders, including Toyo Ink SC Holdings, and the effects on the corporate group and business, etc. Furthermore, if there are special circumstances such as significant loss of corporate value or occurrence of a serious compliance violation at the issuing company, or if there is concern that our corporate value as a shareholder will be impaired, based on adequate amount of information collected through dialogue with the issuing company, etc., we will carefully determine the pros and cons of exercising the voting rights of strategically held shares. |

Principle 5-1. | Toyo Ink SC Holdings considers shareholders and investors as important stakeholders, respects shareholders’ rights, and strives to improve shareholder value, with the aim of “enhancing the satisfaction level of shareholders” as a course of action. Especially, the constructive dialogue with shareholders and investors is recognized as an important factor. The company appoints directors in charge of financial affairs, general affairs, and IR, realizes the information sharing among related sections through organic cooperation, promotes the dialogue with shareholders through the general affairs section and the dialogue with investors through the publicity section, and reports their opinions that are considered important to directors in charge, when necessary. As for the management of insider information, the company produced the regulations for the prevention of insider transactions, the regulations for protecting and managing information, etc. The management of insider information is included in the standards for business activities as a concrete course of action. A guidebook is distributed to all employees of the corporate group, and the employees are educated regularly to diffuse the rules for managing insider information. |

This report is intended solely for information purposes and is not intended as a solicitation for investment. The information and opinions contained within this report are made by our company based on data made publicly available, and the information within this report comes from sources that we judge to be reliable. However, we cannot wholly guarantee the accuracy or completeness of the data. This report is not a guarantee of the accuracy, completeness or validity of said information and opinions, nor do we bear any responsibility for the same. All rights pertaining to this report belong to Investment Bridge Co., Ltd., which may change the contents thereof at any time without prior notice. All investment decisions are the responsibility of the individual and should be made only after proper consideration. Copyright(C) 2020 Investment Bridge Co., Ltd. All Rights Reserved. |