| Ferrotec Corporation (6890) |

|

||||||||

Company |

Ferrotec Corporation |

||

Code No. |

6890 |

||

Exchange |

JASDAQ |

||

Industry |

Electric Equipment (Manufacturing) |

||

President |

Akira Yamamura |

||

HQ Address |

Nihonbashi Plaza Building, Nihonbashi 2-3-4, Chuo-ku, Tokyo |

||

Year-end |

March |

||

URL |

|||

* Stock price as of closing on June 26, 2014. Number of shares issued at the end of the most recent quarter excluding treasury shares.

|

||||||||||||||||||||||||

|

|

* Estimates are those of the Company.

|

|

| Key Points |

|

| Company Overview |

|

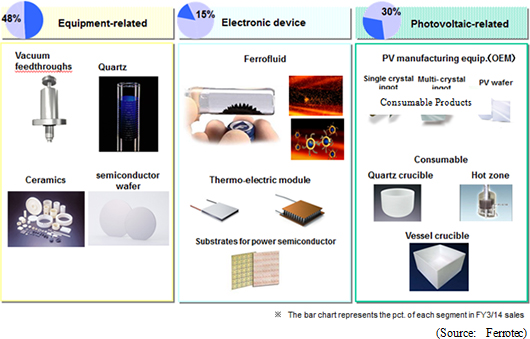

<Business Segments>

Ferrotec's operations can be divided between the equipment related business segment where vacuum seals, quarts products, and other ceramic products used in semiconductor, FPD, and LED related manufacturing equipment are manufactured, electronic device business segment where thermoelectric module application products are made, and photovoltaic business segment where silicon single crystal manufacturing equipment and crucibles used in devices are produced. In fiscal year March 2014, sales of the equipment related, electronic device, and photovoltaic related business segments accounted for 48.3%, 14.8% and 29.5% of total sales respectively, while saw blades, equipment part cleansing, machine tool, and other products not included in reported segments accounts for 7.4%. Moreover, Ferrotec leverages its know-how and technologies for vacuum seals, which are a main product of the equipment related business segment, in its silicon crystal manufacturing equipment.

Equipment Related Business Segment

Ferrotec places a strong emphasis upon, and provides total engineering services in, the equipment related business segment. In addition, the Company provides equipment parts, consumables, spare parts and equipment cleaning services (50% share in China). Vacuum seals, the Company's main products, boast the top market share in the world, and are functional parts that insulate the interior of manufacturing equipment from gas and dust contamination while supporting rotating action of the equipment. Vacuum seals are critical in manufacture of semiconductor, FPD, LED and photovoltaic manufacturing equipment. This product uses ferrofluid (Fluids that respond to magnetic fields), which has been a core technology since the Company's founding. Because of instability in these applications arising from their link with corporate capital investments cycles, Ferrotec focuses its marketing efforts upon expanding sales to applications for which demand is more stable, including transportation equipment, precision robots, and general industry usages. In addition, the Company has also focused its efforts upon assuming consigned manufacture of vacuum chambers that use vacuum seals and gate valves (Both use vacuum related equipment).At the same time, quartz products and ceramic products are critical elements in the process of semiconductor manufacturing. Quartz products are able to resist high temperature conditions that exist in the semiconductor manufacturing process, and are a high purity silica glass product that protects semiconductors from undergoing chemical reaction by preventing it from reacting chemically with gas. Ferrotec boasts of a high share of products purchased by LED manufacturers, in addition to high share of quartz products (Photovoltaic related business) used in the photovoltaic cell manufacturing process. This technology is also being used to cultivate high purity crucibles for use in semiconductor applications. The Company boasts of semiconductor manufacturing equipment manufacturers as their clients in Japan and overseas purchasing ceramic products that are Ferrotec's core material and technology. At the same time, sales of semiconductor inspection jigs for machinable ceramics to flash memory applications are growing. In addition, Ferrotec has achieved 300,000 units per month of small wafer processing (Ingot slicing) for discreet semiconductor applications, and its contribution are becoming significant. Electronic Device Business

Thermal element "thermoelectric modules" are products that can instantly raise or lower temperatures to highly precision and are core products of the Company's electronic device business. Thermoelectric modules are used primarily in heated automobile seats, and also in a wide range of other applications including genetic analysis equipment, optical communications, and consumer electronics. Ferrotec is also devoting efforts to expanding the range of applications for high-performance material by improving product quality, introducing automated manufacturing lines to reduce costs, and developing new products that are high in functionality. Sales of ferrofluids, including applications currently being developed for use in fishing reels (Water protecting internal seals) and speakers for 4K televisions, are also conducted in this segment.

Photovoltaic Related Business

Ferrotec entered the photovoltaic related business in 2005, and has manufactured and sold silicon crystal manufacturing equipment, consumable products including quartz crucibles, and silicon products. Based upon the current needs of the market, the Company is conducting consigned manufacturing of silicon crystal ingots and wafers used in photovoltaic substrates, as well as manufacture and sales of silicon-use multiple crystal vessels and single crystal crucibles manufactured when making ingots (both based on quartz processing technologies). With regards to consumable products like crucibles, Ferrotec boasts of a high market share due to its wide-ranging lineup of products and ability to manufacture customized products.

<New Endeavors>

With the goal of preserving the environment and contributing to the development of new energies, Ferrotec has been implementing horizontal deployment of its technological, manufacturing, and sales capabilities and invest in product research and development. Some examples of new product research and development include jet valves used in exhaust gas pollutant reduction technologies, high purity single crystal silicon ingots used in high purity crucibles, and waste heat power generation (Power boards) using thermoelectric modules. All of these products and technologies are necessary to protect the environment, conserve energy, and will lead to technological innovations. Furthermore, they leverage the technologies and manufacturing facilities of Ferrotec.

|

| Fiscal Year March 2014 Earnings Results |

Sales Rise 16.4%, Ordinary Income Improve to a Profit of ¥1.262 billion from a Loss of ¥3.465 billion in Previous Term

Sales rose by 16.4% year-over-year to ¥44.745 billion. Sales of the electronic device business rose by 44.8% year-over-year to ¥6.609 billion on the back of strong demand for thermoelectric modules used in automobile seat automated heating applications. At the same time, equipment related business rose by 14.6% year-over-year to ¥21.628 billion due to recoveries in semiconductor investments and improvements in semiconductor manufacturer capacity utilization rates during the second half. In addition, sales of the photovoltaic related business rose by 7.0% year-over-year to ¥13.203 billion due to favorable demand for photovoltaic use silicon (OEM provision) and despite weak capital investments and capacity utilization rates of module manufacturers.With regards to profits, the higher sales and decline in valuation losses resulting from the implementation of lower of cost or market accounting methods allowed gross income to rise by 55.1%. At the same time, sales, general and administrative expenses declined by 5.3% year-over-year on the back of successful business restructuring and reductions in labor and other fixed costs. Consequently, operating income improved from a loss in the previous term of ¥3.608 billion to a profit of ¥798 million in the current term. An improvement in non-operating income arising from an increase in foreign exchange translation gains (¥870 million to ¥1.475 billion), which offset business restructuring costs of ¥443 million, allowed ¥1.262 billion in ordinary income to be recorded. Liquidation of marketable securities totaling to ¥1.360 billion allowed extraordinary income of ¥1.378 billion to be recorded and contributed to the improvement in net income to a profit of ¥1.391 billion (An extraordinary loss of ¥3.656 billion arising from business restructuring expenses recorded in the previous term). Average foreign exchange rates of ¥97.99 per United States Dollar and ¥12.73 per Chinese Yuan were recorded (Compared with ¥80.12 and ¥15.97 to the Dollar and Yuan respectively in the previous term). Based upon foreign exchange rates observed in fiscal year March 2013, fiscal year March 2014 sales, gross income, sales, general and administrative expenses, and operating income would have been ¥39.0 (Up 1.5% ), ¥9.410 (Up 34.9%), ¥8.670 (Down 18.1%), and ¥0.740 billion ((Down 1.2%) respectively.  (2) Term End Dividend Payment of ¥6 Anticipated

Initial plans called for a dividend payment of ¥5 per share at the term end, but Ferrotec now expects to raise its payment by ¥1 to ¥6 per share for a dividend payout ratio of 13.3%.

(3) Financial Conditions and Cash Flow

Total assets at the term end rose by ¥8.379 billion from the end of the previous term to ¥74.723 billion. After adjusting for foreign exchange (Term end rate of Yen to Dollar of ¥88.58 rose to ¥105.39), the assets and liabilities of overseas subsidiaries rose by large margins in Yen terms. Net assets rose on the back of foreign exchange translation provisional accounts from ¥74 million at the previous term end to ¥6.741 billion at the current term end. Consequently, equity ratio improved by 5.3% points from the end of the previous term to 50.2% at the end of the current term.Moreover, current, fixed, and total assets would have amounted to ¥34.620 (Up ¥350 million), ¥28.760 (Down ¥6.1 billion) and ¥63.390 billion (Down ¥2.950 billion) respectively if the exchange rates of ¥105.39 per US Dollar (End March 2014) and ¥17.36 per Chinese Yuan (End December 2013) were used. Interest bearing liabilities excluding lease liabilities stood at ¥18.096 billion, but based on the same foreign exchange rates as the previous fiscal year (US Dollar and Chinese Yuan interest bearing liabilities) would have actually declined by ¥2.1 to ¥16.433 billion.    |

| Fiscal Year March 2015 Earnings Estimates |

Sales, Operating Income to Rise 11.7%, 125.5%

Ferrotec's estimates call for sales to rise by 11.7% year-over-year to ¥50.0 billion. By business segment, sales of the equipment-related business, photovoltaic related, and electronic device businesses are expected to rise by 3.1%, 22.3% and 14.2% year-over-year to ¥22.3, ¥16.150, ¥7.550 billion respectively.With regards to profits, increases in capacity utilization rates arising from higher sales and cost reductions are expected to allow operating income to rise by 125.5% year-over-year to ¥1.8 billion (Operating margin expected to rise from 1.8% in the term just ended to 3.6%). Ordinary and net incomes are expected to decline due to the disappearance of foreign exchange translation gains and extraordinary profit. Capital investments are expected to remain within the range of depreciation at ¥3.0 billion (Down 21.6% year-over-year, additional investments to increase efficiencies at existing facilities, investments in projects that are expected to be profitable and for which orders have been acquired, and investments to reduce cost of sales), while depreciation is expected to increase by 6.7% year-over-year to ¥4.2 billion. Ferrotec bases its estimates upon foreign exchange rates of ¥102 per United States Dollar (¥97.99 in FY3/14), and ¥16.5 per Chinese Yuan (¥15.96-¥15.97 in FY3/14). (2) Second Year of Higher Dividends Expected

Dividend payment is expected to be raised by ¥2 to ¥8 per share at the end of the fiscal year March 2015 for a dividend payout ratio of 35.2%.

|

| Segment Sales Trends and Estimates |

Equipment-Related Business: FY3/14 Sales Up 14.6% to ¥21.628 Billion → FY3/15 Sales Up 3.1% to ¥22.3 Billion

Vacuum Seals: Sales Rise 32% on Strong Demand from Semiconductor Applications, FPD, LED, Photovoltaic Up 14%, 13%, 2%

During fiscal year March 2014, sales rose by 15.7% year-over-year to ¥5.422 billion. While capital investments in high purity, fine, small to medium liquid crystal equipment have deteriorated, declines are being absorbed by increases in demand from major semiconductor manufacturers due to their relaunch of capital investments, expansion of consigned manufacturing by semiconductor manufacturing equipment manufacturers that have entered China, and increases in sales to robot manufacturers. During fiscal year March 2015, sales are expected to rise by 7.0% year-ove-year to ¥5.8 billion. Sales to equipment manufacturers are expected to be influenced by a peaking of capital investments for three dimension, miniaturization is expected during the first half, but consigned manufacturing trends are expected to remain favorable on the back of increases in demand from the automobile industry and semicoductor industies. Ferrotec is expected to strengthen its marketing efforts to capture demand from a wider range of applications including subassemblies and engeineering after service in general use industrial applications. Quartz Products: Sales to OEM, End Users Account for 65%, 18%

Sales rose by 31.1% year-over-year to ¥4.484 billion during fiscal year March 2014. Both capital investments by integrated circuit manufacturers within Japan and in other parts of Asia, and OEM supplies to major semiconductor manufactuers in the United States and Japan recovered. In addition, approval has been received for the start of production of high purity products at plants in China. At the same time, demand for short delivery times and price reductions are continuing.During fiscal year March 2015, sales are expected to rise by 4.8% year-over-year to ¥4.7 billion. Orders are expected to continue to trend at high levels on the back of favorable OEM supplies to major semiconductor manufacturers in the United States and Japan, and favorable investments by integrated circuit manufacturers. Moreover, production of high purity products is expected to grow. Ferrotec will implement efforts to improve profitability through materials cost reductions and to maintain product pricnig by fortifying its high value addition products including silicon parts for next generation and new machinery applications. The Company will strengthen its marketing efforts to Taiwanese companies by leveraging its strengths of short delivery times, stable product quality, and ability to provide customized products. Ceramic Products: Machinable Ceramics for Inspection Jigs 46%, Semiconductor Use Fine Ceramics 46%

Sales declined by 3.5% year-over-eyar to ¥3.865 billiion during fiscal year March 2014 (January to December). Demand for machinable ceramics (Product name: Photoveel) from the memory (N/Flash) recovered towards the end of the term. At the same time, supplies to Taiwanese and Korean manufacturerrs declined on the back of production adjustments for non-memory (Logic) products used in high functionality smartphones. Moreover, sales of products to organic EL manufacurers fell below plans due to delays in mass production, but demand from medical equipment manufacturers in the United States improved on the back of the start of mass production during the second half. At the same time, demand for fine ceramics from Taiwanese manufacturers picked up from the start of the year on their investments for miniaturization, and demand from major integrated circuit manufacturers underwent a rapid recover during the second half on the back of their investments in three dimension and miniaturization.Sales during fiscal year March 2015 (January to December) are expected to rise by 3.4% year-over-year to ¥4.1 billion. Demand for machinable ceramics is expected to grow on the back of SSD demand from memory (N/Flash) applications, and demand for non-memory (Logic) products is expected to continue to recover on an expansion in mobile device market in developing countries. While demand for fine ceramics is expected to slow during the middle of the coming year due to delays in fab investments, capital investments for three dimension and miniaturization are expected to continue in 2015. EB Gun, Deposition Equipment

Sales rose by 19.0% year-over-year to ¥3.242 billion during fiscal year March 2014 on the back of a gradual recovery in demand. However, there appears to be a break in the recovery in demand near term, and severe conditions within the LED market are expected to lead to a 4.4% year-over-year decline in sales to ¥4.6 billion during fiscal year March 2015. In addition to the focus of marketing efforts upon the optical market, Ferrotec will also leverage its capabilities in the European market.

Wafer Processing

Sales during fiscal year March 2014 rose by 14.9% year-over-year to ¥4.515 billion. A recovery in the market contributed to an increase in sales of own branded products, with particular strength in demand being noted in the China and Taiwan markets. Despite increases in the number of wafer products, the long amount of time required to recive approval is expected to delay their full contribution to profitbility until after the coming term. During fiscal year March 2015, sales are expected to rise by 1.9% year-over-year to ¥4.6 billion based upon the outlook for a continuation of favorable conditions and subsequent increases in sales in China and Taiwan. Investments for mass production and facilitaiton of a structure to achieve higher levels of technology and product quality are expected to be implemented by Ferrotec.

Electronic Device Business: Sales Rise 44.8% to ¥6.609 Billion → Expected to Rise by 14.2% to ¥7.550 Billion in FY3/15

Thermoelectric Modules Produccts: Automobiles, Biotech, Optical Communication, Semidoncutor, Physicochemical Equipment, Optical Applications to Account for 65%, 8%, 5%, 4%, 4%, 3%

Sales rose by 46.7% year-over-year to ¥6.054 billion during fiscal year March 2014 on the back of strong demand for automobile seat automated heating applications, and for nearly all other applications. Full scale provision of products used by major manufacturers of power device boards was also started. Sales during fiscal year March 2015 are expected to rise by 14.8% year-over-year to ¥6.950 billion due in part to the outlook for continued strong demand for automobile seat automated heating applications and for other applications. Sales of power device board use products are expected to expand on the back of an expansion of the variety of board applications. In addition to efforts to fortify marketing for power device boards, new applications of thermoelectric modules sold to new users are expected to be launched.

Photovoltaic Related Business: FY3/14 Sales Rose 7.0% to ¥13.203 Billion → FY3/15 Sales to Rise 22.3% to ¥16.150 Billion

Crucibles: Single Crystal Crucibles and Multiple Crystal Vessels Boosted Photovoltaic Related Sales 28% in FY3/14

Sales in fiscal year March 2014 rose by 36.5% year-over-yeare to ¥3.699 billion, due in part to a gradual recovery in demand arising from the bottoming in single crystal crucible demand. Pricing trended sideways while volumes increased. Demand for multiple crystal vessels from Taiwanese companies recovered. Sales during fiscal year March 2015 are expected to rise by 22.3% year-over-year to ¥4.500 billion due to the outlook for continued increases in sales volumes despite a lack of recovery in pricing for single crystal crucibles and multiple crystal vessels. Ferrotec will endeavor to increase pricing through the introducton of long life products, and by responding to changing needs of customers for single crystal crucibles with additional charges (Additional raw material load. Increases in heat usage efficiency and crucible usage efficiencies are expected.). Furthermore, the transfer of manufacturing to the Yinchuan Plant is designed to reduce costs. Moreover, Ferrotec will focus its efforts upon expanding sales of semiconductor use crucibles, and to gain approval of its products by Japanese semiconductor manufacturers.

Photovoltaic Use Silicon: Photovoltaic Related Business Sales Up 57% in FY3/14

Sales rose by 37.4% year-over-year to ¥7.570 billion. Strong demand in Japan, China, and the United States was complemented by the launch of business in developing countries like India. However, demands of customers for higher functionality and lower prices contributed to increased competition and weaker pricing. Amidst these trends, sales were successfully grown during fiscal year March 2014 by focusing upon OEM supply of N type crystals that boast of superior electricity generation efficiency. During fiscal year March 2015, sales are expected to grow by 14.9% year-over-year to ¥8.770 billion on the back of acquisition of new OEM customers of this N type crystal with superior electricity power generation efficiency. At the same time, demand within China for multiple crystal products is expected to be strong. Currently, the Yinchuan Plant is operating at full capacity and steps will be taken to increase capacity there so that production of N type single crystal silicon can be achieved to expand sales. In addition, Ferrotec is also considering increasing its facilities for wire saws (Ingot slicing equipment) to respond to strong demand for fixed abrasive grain and thin wafers.

|

| Conclusions |

|

Over the medium term, Ferrotec is expected to implement measures that leverage its strengths in vacuum and precision processing technologies to implement measures that leverage its strengths in vacuum and precision processing technologies in the realm of industries where expansion of market is expected, namely food, water, energy, communications and medical fields. Within the medical field, negotiations for sales of vacuum chambers, seals, and other parts used in CT scan and MRI equipment are being conducted with Chinese manufacturers. At the same time, negotiations for sales of thermoelectric modules used in medical equipment power board made by European medical equipment manufacturers are also being promoted. Ferrotec has been leveraging the long life and highly accurate temperature control functions of its thermoelectric modules used in blood analysis equipment (DNA and PCR analysis equipment) that have allowed it to achieve 90% market share. Disclaimer

This report is intended solely for information purposes, and is not intended as a solicitation to invest in the shares of this company. The information and opinions contained within this report are based on data made publicly available by the Company, and comes from sources that we judge to be reliable. However we cannot guarantee the accuracy or completeness of the data. This report is not a guarantee of the accuracy, completeness or validity of said information and or opinions, nor do we bear any responsibility for the same. All rights pertaining to this report belong to Investment Bridge Co., Ltd., which may change the contents thereof at any time without prior notice. All investment decisions are the responsibility of the individual and should be made only after proper consideration.

|